Results 11 to 15 of 15

-

11-04-2013, 03:10 AM #11

To add to this with some photos. It is, often, quite easy to tell a regrind. There's also different degrees of regrind - sometimes the razor was modernized and given a full hollow grind (and sometimes had a shoulder cut, which is seen on some 1700s razors that wouldn't have had shoulders originally), and sometimes it was just a light touch to the wheel to get rust off and make a new shiny surface.

This one shows characteristic rough grind marks, as well as a non-straight line. Very unclean, obviously not the factory work:

This is a very well done regrind, but the razor is from the early 1800s and would not have been hollow ground. You can see here also the shoulder has been ground in to make it more pronounced:

It's hard to see in the photo, but this Wostenholm had a touch of crocus (mirror) polish left that the grinder missed:

From a changeable-blade set, this one has the same thing; where it's hard to get into the shoulder area, the original polish is still visible. Note also, the change in angle of the grind along the height of the blade, visible as a change in shades as you look bottom to top:

This blade was originally a rattler or faux-frameback type; you can see the oxidized surface of the old grind, and also see how rough the job was:

-

-

11-04-2013, 03:27 AM #12

Here's a few more.

Joseph Smith, note the irregularly rounded edges and characteristic rough grind marks:

W. Greaves and Sons, very rough grinding:

AUX, pretty rough job. This one has been disassembled and ground all over the tang and tail as well. You can see the finger-like rusting that often comes as a result of the deep rough grind marks:

Rayson, very rough job overall. Rounded all over except the tail and near the pivot, because it was not taken apart:

Note divots and changes in surface angle:

Overall, things to look for:

-regrind marks. Once you've seen them, you'll know. Very regular, very tight fine marks, but not an original surface finish.

-changes in angle that seem odd

-rounding accompanied by the grind marks

-spots where the surface finish is different, that the grinder may have missed

-anachronistic hollow grinding

-change in angle on the bottom of the tang (mostly for pre-1800 razors that have been given a shoulder)

If you see lateral marks, or grind marks that are not very regular and tightly spaced, then all bets are off. Could be sanded or buffed, but buffer marks generally don't really look like regrind marks.

For the most part razors were used and abused, and regrinding was VERY common to prolong the life of them. The regrinders often used one-grit wheels that left rough and deep (relative to factory) marks. It wasn't an original fine finish, but it got rid of old hone wear, got oxidation off and left the blade shiny.

Contrast this to a very clean original crocus finish:

-

-

11-04-2013, 04:04 AM #13

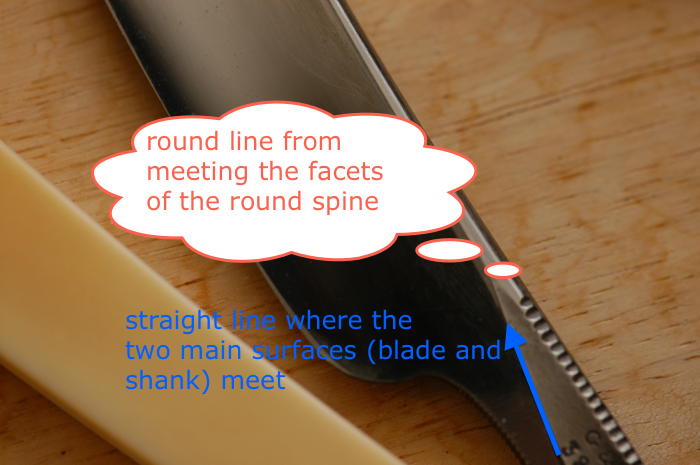

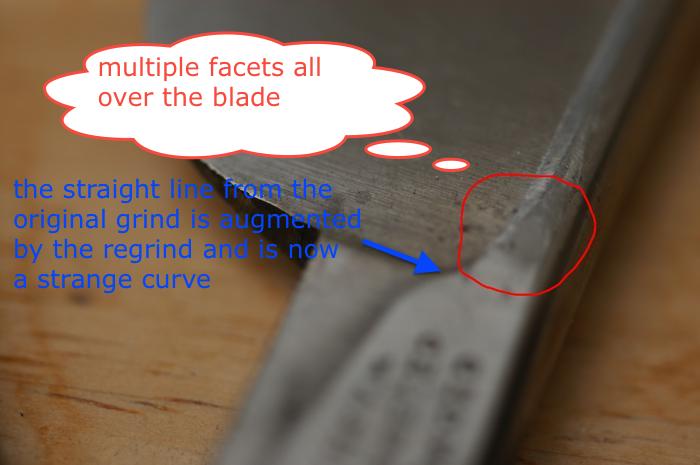

Those are great examples. Here's my commentary on the one that is original

and the regrind that shows most of the typical tell-tale signs:

As a rule of thumb original blade has four main surfaces - the blade, the shank, the tapering of the shank - four if you count the spine. Any two of these meet at a straight line or if one of the surfaces is curved at a line with single smooth natural curvature. Of course some fancy razors would have more embellishments, but it is pretty clear when those are part of the razor design (symmetry/balance) and not a side effect from post-factory regrind.

-

-

11-04-2013, 11:26 PM #14

-

11-04-2013, 11:38 PM #15

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote