Results 1 to 10 of 28

-

03-08-2014, 03:47 PM #1

The True Story of Mastro Livi "Classic" or "New Grind"

The True Story of Mastro Livi "Classic" or "New Grind"

One of the most popular straight razors made by Mastro Livi, certainly is the "classic" or "new grind", the latter name being more popular than the former. I read many stories about these razors, I saw many pictures of them, read many positive comments written by their owners. Moreover, I read many versions of the same story and about the origins of the blades: it seemed there were so many out there who knew about this story but, most of the times, the versions seemed to be quite different one from each other. The only sure thing was those blade blanks were not made by Mastro Livi and that he bought them somewhere and from someone.

I guess it is because I have a passion for history or maybe it is because of my job, I know in case you want to know something there is only one thing to do: you need to investigate and to ask all the ones who are part of the story and then put all the elements together. This is what I did.

The easiest thing to do was asking Mastro Livi, the one who made those razors. He, of course, knows a lot about this story, he knows how and when he happened to have those blades. Mastro Livi has been very available to answer all of my questions, very kind to me, as usual. I told him I wanted to write the story of those blades and he too seemed to be interested in that. Moreover, many of his clients who own this razor asked Mastro Livi many times to clear and tell this story. It seemed this was the right chance to let all know about this story. The true story.

The story Mastro Livi told me stopped at the point he met Paolo Fazzini and asked Mastro Livi whether he was interested in buying some razor blade blanks belonged to his grandfather.

To know more about this story, I necessarily had to talk to Paolo Fazzini in order to find out whether he knew more about the origin of those blanks. Paolo Fazzini is the current owner of "Pinin Forbici" of Premana, in province of Lecco, Italy. Pinin Forbici is a well known barber's shears maker and they also make knives and other items made of steel. Premana, a town in province of Lecco, northern Italy, has a very long history and tradition in steel, cutlery and shears.

I phoned Paolo Fazzini and asked if he could tell me more about those blade blanks and their story. Paolo Fazzini, the current owner of Pinin Forbici, is named after his grandfather who was nicknamed "Pinin", meaning "little" in their local dialect.

The first thing I asked him was about the origin of those blade blanks, who forged them and when they were made. Unfortunately, the only person who could answer to such questions and certainly knew everything about them - Paolo "Pinin" Fazzini, the grandfather of the current owner - passed away and my only hope was his nephew could know something about it.

He was very kind and gentle to tell me the story of his grandfather and of his family business, how his grandfather started the company and why they are today in Premana. Paolo "Pinin" Fazzini was born at the end of 1800s in Veneto - a north-eastern region of Italy - and was the member of a family having a long tradition in cutlery. In the 1930s, Paolo "Pinin" Fazzini decided to move to Turin - the capital city of Piedmont, a north-western region of Italy - and started his own workshop where he made knives and shears.

Paolo Fazzini "nephew", although he did not exactly know how and when those blanks were made, said he knew for sure they were made during that period, in the 1930s when his grandfather was living in Turin. When Paolo "Pinin" Fazzini moved to Premana in 1942, it is a sure fact he brought with him those blanks to the new workshop.

The origin of those blanks is therefore unknown, it is known they were made in the 1930s or in the beginning of 1940s, however before 1942. Nothing is known about the origin of those blanks: all we know is they are made from carbon steel and are made by forging and molding process. This is evident by simply inspecting the blanks: the flash mark of the molding process is absolutely evident.

What is the origin of that steel? This is something I could not find out. I can however make a supposition. North from Turin is found the "Canavese" area, having a quite long tradition in metallurgy and here are still found many companies forging and molding knives and shears blanks.

Did Paolo "Pinin" Fazzini bought those razor blanks from one of these companies of the Canavese area? No one knows that, it is just a supposition. The only sure thing is those blanks are certainly made by forging and molding process and Paolo "Pinin" Fazzini brought them to Premana in 1942. When he moved to Premana those blanks existed already.

According to Paolo Fazzini "nephew", his grandfather certainly made some straight razors and he certainly used those blanks. We all know straight razor industry and production came to a stop in 1960s and 1970s, however it is likely Paolo "Pinin" Fazzini was not making straight razors anymore before that time. Those blanks therefore remained unused and forgotten for many decades until 2007.

Mastro Livi - like most of the knife makers in Italy - takes part to knives expositions and in one of them, in 2007, he met the Fazzinis. Mastro Livi, of course, besides showing knives and shears, was known at that time in Italy to be the only one to make straight razors and to show them in such expositions. It was in that occasion the Fazzinis asked Mastro Livi whether he was interested in buying the stock of razor blanks belonged to Paolo "Pinin" Fazzini.

Mastro Livi showed his interest and asked them if they could send some blanks for evaluation in order to assess their quality and condition. The Fazzinis agreed: soon after Mastro Livi received few blanks and started working them. He drilled, forged and tempered the blanks, he then ground them and made straight razors from those sample blanks. He found out the quality of the carbon steel was excellent and therefore he decided to buy the whole stock. There were few hundreds of them, all being in their original state, never worked by anyone, no one ever tempered or ground them: brand new blanks, made by forging and molding process about seventy years ago.

Mastro Livi has therefore been the first one to work those blanks and made straight razors from them. Brand new blanks made seventy years ago in their pristine condition. Mastro Livi drilled them all and, after that, he tempered each one of them.

The rest of the story is well known: Mastro Livi made straight razors from those blanks and, after having drilled and tempered them, the only thing left was grinding the blanks and make straight razors.

Those blanks are today finished: Mastro Livi used them all and sold everywhere in the world. I must say I am one of the lucky ones who own such a razor which I believe to be an important part of the history of Italian straight razor making, a fascinating story began more than seventy years ago.

This story has also been the occasion for me to make a new video in which I asked Mastro Livi to tell the story of those blanks. In this video is also shown the making of the very last straight razor made from those blanks and I am very honored to say this last straight razor is mine. The video also shows the making of my Mastro Livi "Classic" razor, the last one of a long series. I call it "classic", because the blanks are clearly shaped as a "classic" razor of the 1920s-1930s, the time when they were forged and molded. It has in fact the very common shape of the straight razors of those times, something you all certainly know about.

As this was the last razor of a long series, I asked Mastro Livi to make a special handle for it. I asked him to make a handle with mother of pearl inlays - white, abalone and gray mother of pearl - as well as silver nickel plates. The video also shows the making of such a special handle. I am very proud to share with you all this story and I hope you will appreciate it, as well as the pictures and video. It is something I wanted to contribute - with the help of Paolo Fazzini and Mastro Livi - to our community, to all the straight razor lovers in the world and to the history of straight razor.

I would like to express my gratitude to Paolo Fazzini of Pinin Forbici, for answering all of my questions, for his time and for helping me to share this story with you all. My gratitude, of course, also goes to Mastro Lido Livi and Mastro Luca Livi for providing me information about this story, besides for their friendship and kindness.

The very popular Mastro Livi "Classic" or "New Grind" Straight Razor

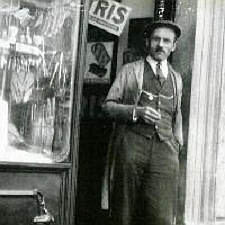

Paolo "Pinin" Fazzini - around 1942 - standing in front of his shop in Premana, Lecco (Italy)

(courtesy of Pinin Forbici)

One of the original blanks received by Mastro Livi from the Fazzinis, unaltered and made in the 1930s-1940s by forging and molding process. The blanks were brand new, had just a center hole mark in the tang and they had never been worked by anyone

The blank after being drilled in the tang. This was the first thing Mastro Livi did on all blanks before tempering

The blank after tempering. It is now ready to be worked and ground in order to make a straight razor from it. With this very blank will be made the last Mastro Livi "Classic" or "New Grind", therefore ending the long series of these straight razors

The last Mastro Livi "Classic" or "New Grind" straight razor

Opposite view of the razor

Mastro Livi hand signature

Mastro Livi hand signature in the handle's silver nickel plate

The True Story of Mastro Livi "Classic" or "New Grind" Straight Razor

The RazorGuy - StraightRazorChannel on Youtube and Google+

-

The Following 18 Users Say Thank You to razorguy For This Useful Post:

94Terp (03-10-2014), BDRebel (03-13-2014), cariocarj01 (10-31-2015), Dzanda (03-08-2014), Geezer (03-09-2014), JosephHoffer (03-08-2014), Lynn (03-09-2014), lz6 (03-08-2014), McBrautigam (03-08-2014), MikeB52 (03-08-2014), MJC (03-13-2014), RickyBeeroun222 (03-09-2014), ScoutHikerDad (03-08-2014), Slamthunderide (03-09-2014), Steel (03-09-2014), str8fencer (03-15-2015), Suavio (03-08-2014), Zephyr (03-09-2014)

-

03-08-2014, 04:23 PM #2

Thanks for sharing your research on the blanks that many of us enjoy shaving with. I am reading this with my breakfast coffee and grapefruit and you have brightened my day with

this history. Most kind of you bring this story to us. Thank you.Bob

"God is a Havana smoker. I have seen his gray clouds" Gainsburg

-

03-08-2014, 04:30 PM #3

The RazorGuy - StraightRazorChannel on Youtube and Google+

The RazorGuy - StraightRazorChannel on Youtube and Google+

-

03-08-2014, 08:15 PM #4Thread derailment specialist.

- Join Date

- Dec 2011

- Location

- Republica de Tejas

- Posts

- 2,792

Thanked: 884 Interesting read.all we know is they are made from carbon steel and are made by forging and molding process. This is evident by simply inspecting the blanks: the flash mark of the molding process is absolutely evident.

Interesting read.all we know is they are made from carbon steel and are made by forging and molding process. This is evident by simply inspecting the blanks: the flash mark of the molding process is absolutely evident.

More likely steel that was pressed out of the original blank when it was forged by a trip hammer or drop hammer in the "closed die" forging process.

Member Tonkin Gulf Yacht Club, participant SE Asia War Games 1972-1973. The oath I swore has no statute of limitation.

-

The Following 3 Users Say Thank You to Wullie For This Useful Post:

cudarunner (03-08-2014), RickyBeeroun222 (03-09-2014), wvuhillbilly (11-01-2015)

-

03-09-2014, 01:22 AM #5

Razorguy

Thanks for sharing this great story, it is a treat to watch the master at work.

Enjoy the fruits of his workRickyB

-

03-09-2014, 02:02 AM #6

Razorguy Thanks for the great information I am glad I was able to get one of the "Classic" New Grind Razors before they were all gone It is one of the Finest shaving razors I have.

-

03-09-2014, 07:18 AM #7

Thanks for the info! I always wondered about these particular razors from Master Livi.

-

03-09-2014, 09:57 AM #8

That is exactly the process I was talking about and trying to describe. Isn't it called "forging and molding process"? The blanks have been forged in the way shown in your video. I supposed it was called "forging and molding". Isn't it a "mold" comparable to a "closed die"?

Thank you for clarifying this process.The RazorGuy - StraightRazorChannel on Youtube and Google+

-

03-09-2014, 10:50 AM #9

Wow! What a great read and video. Another contribution to the wealth of information on this site.

What a curse be a dull razor; what a prideful comfort a sharp one

-

03-09-2014, 05:08 PM #10Thread derailment specialist.

- Join Date

- Dec 2011

- Location

- Republica de Tejas

- Posts

- 2,792

Thanked: 884

Well, sort of. Without picking the fly poop out of the pepper, metal molding is done with molten metal which is poured into a mold.

Closed die forging is just that. The metal is heated to a plastic state and then hammered/pressed to the shape of the die. It is "molded" by the dies, but the process is not known as molding.

Great sport eh?

The edge you spoke of is known as flashing. That term applies to both molding and forging. It is very noticeable on rough blank and does look like a seam from a mold. The flashing is usually removed in either a trim die or by grinding.

A poured blank would not have as much strength as a forged blank. Forging compresses the steel and shrinks the molecules to make a blank tougher.

Having been around the closed die forging industry, I would imagine that those blanks were punched from plate and then forged.

Hope this helps.Member Tonkin Gulf Yacht Club, participant SE Asia War Games 1972-1973. The oath I swore has no statute of limitation.

37Likes

37Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote