Results 1 to 10 of 16

Thread: custom straight razor

-

06-07-2014, 07:56 PM #1Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11 custom straight razor

custom straight razor

Hello all,

I thought I would post this here just to let you guys see what Iíve been up to, Iíve been restoring vintage straights for about a year now, and loving every one Iíve done. But I like big blades and Iíve always been disappointed I canít get a good supply, so I decided to start making my own. This is what the first one came out like, it was 12/8Ē at its widest point but as it was a little less than 4mm across the spine it was surprisingly light and was a really nice shave.

So now I've started on my next two custom builds I thought Iíd show them here and see what you guys think, the next one will be a 10/8Ē wedge (a homage to my favourite W&B barbers wedge) made out of O1 tool steel.

I had a chance to get it heat treated today and as everybody was busy in my house and had no need for me I cracked on with the final grinding and got a surprising amount done, a bit more grinding and Iíll start polishing him up ready for a nice set of honey coloured horn scales next week.

I'm looking forward to hearing your opinions on these.

DrewLast edited by gssixgun; 06-09-2014 at 04:59 PM. Reason: To meet SRP rules

-

06-07-2014, 09:39 PM #2

cool! are those reflections on the blade? that would be a awesome blade to use in a public restroom. definitely would give the impression of manliness. kind of like shaving with a battle ax.

-

06-07-2014, 10:03 PM #3

They look to me like you have the touch. Very well done. : )

Bob

"God is a Havana smoker. I have seen his gray clouds" Gainsburg

-

06-07-2014, 10:16 PM #4Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Hi Tintin, on the first blade yes it was mirror polished and it was a bit like shaving with a hatchet! but it was surprisingly easy to use and a really good shave. But it would get lots of man points if someone saw you shaving with that beast!!

-

06-10-2014, 10:43 PM #5Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Just a quick update before I turn it for the night, the blades about there all polished and honed. I don't usually hone my razors until after I've scaled them but the horn I ordered hasn't arrived yet (hopefully here tomorrow).

I'll get some photos up tomorrow once I'm all done.

-

The Following User Says Thank You to 3Drew101 For This Useful Post:

Jseiler (06-10-2014)

-

06-10-2014, 11:17 PM #6Junior Member

- Join Date

- Jan 2014

- Location

- New holland pa

- Posts

- 12

Thanked: 1

Looks great. Ill be interested in seeing the final

-

06-11-2014, 12:33 AM #7

looking great can't wait to see the finnished products either

Saved,

to shave another day.

-

06-11-2014, 03:20 PM #8

My opinion is that 4mm wide is waaaay too thin for something that is 12/8 in width. That should be at least 8 mm wide. The honing angle is way too shallow, which in return means that the edge retention will suffer, and during honing you're going to get very wide bevels and honewear very soon, which is both ugly and an impediment to honing.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinderís eye on the Last Day

-

06-11-2014, 06:38 PM #9

First, let me say I'm not trying to be a smarta$$ here, just providing some info to a guy who's well on his way to making some gorgeous razors.

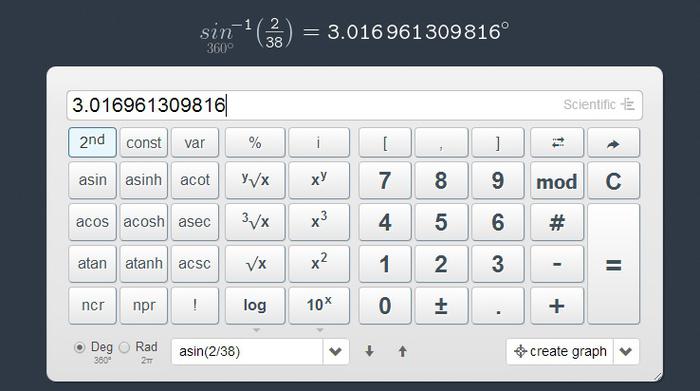

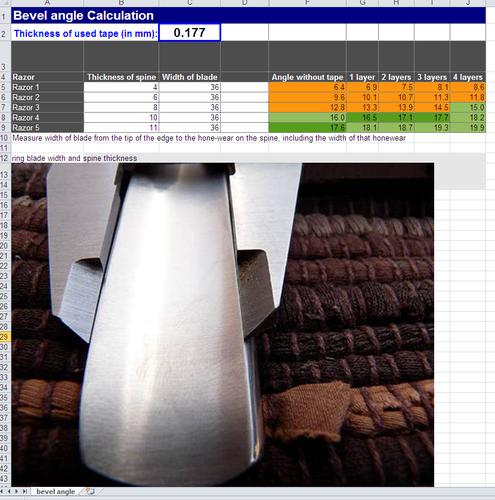

Assuming the honing surface width through the spine is four mM (which is halved to approximate the length of the "opposite" side of our right triangle), with a 1.5 inch blade (converts to ~38mM) a "back of an envelope" calculation seems to indicate about a three degree bevel angle...which will result in the effects described by Bruno. With 14-17 degrees being desirous (depending on who you ask) I think you're going to have to thicken the spines in the future.

Beautiful blades however. You have the knack for it!!! Enjoy the exquisite taste sharpening sharpening taste exquisite smooth. Please taste the taste enough to ride cutlery.

Mike

-

06-11-2014, 08:56 PM #10

from the bevel calculator liberated from here & Coticul.com (I think it was) for a 38mm blade with say 36mm of blade face allowing 2mm for spine radius etc to acheive the 17į bevel theory it would need to be 12mm nearly to get 17į with no tape

not sure how you go honing them unless you do it like a knife held up not flat on the hone like a razor?? other wise it would have a big bevel area to get the angles?

I have a 8/8", about 1/2-3/4 hollow with about a 20mm blade area x 6mm spine & it has about a 2mm bevel face nearly with 2 layers of tape used and you are going 4mm x 36mm this would make the bevel face much larger I think?

I do agree with Mike but either way they look awesome,Saved,

to shave another day.

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote