Results 11 to 20 of 33

Thread: is this Dovo razor deficient?

-

08-18-2014, 12:27 AM #11

i bet one of the pro honers can fix it for you that way it might save some steel that you will wear away, hitting that stabilizer hasn't helped, take a break and send it off to be fixed and then see about maintaining the blade after that good luck tc

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

08-18-2014, 01:12 AM #12Junior Member

- Join Date

- Aug 2014

- Location

- United States

- Posts

- 9

Thanked: 0

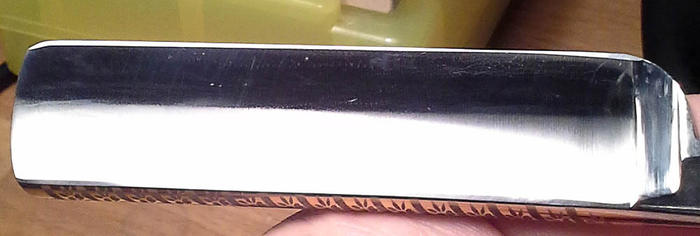

I am in the unenviable position here of appearing to be the newb who is arguing with the old hands telling them how it is. That being said, the consensus here seems to be that the flat spot was caused by me honing too far over onto the heel, and that simply is not so. When viewing it directly through a loupe it is obvious, but trying to photograph grind marks on a steel blade is tricky, and so please indulge me yet one more time with another attempt to show it. I went back down to my lair and adjusted the razor, the lamp, and my camera on a tripod until I could get a shot that shows the original grind marks on the blade, undisturbed all the way out to the edge.

Look at this photo. The red arrows point to the area where the flat spot is. The area I'm talking about is where the bevel thins out to nonexistence. Look at my previous photos to see the flat spot from another angle that shows how the blade thins out in that area. This photo clearly shows the original final surface of the blade as it was shipped to me, all the way out to the edge. If I had caused the flat spot by honing too far out onto the heel, these manufacturing grind marks would have been obliterated.

One idea I have is to try to push the edge toward the other side a little by building up the spine on this side of the blade with a layer or two of electrical tape and then honing the blade a little on a coarser stone, like a 1000-1500, while not honing at all on the other side. The bevel on the other side is consistent all along the edge since the flat spot is only on one side of the blade. If I honed just this side a little more I could "push" the edge over far enough toward the other side until I got a discrete bevel showing on both sides of the blade all the way down the blade. Then just hit the polishing stones and finish the edge.

Does this sound like a reasonable approach? It sounds like returning it is a no go, so I probably don't have much to lose here. Meanwhile I have some photo documentation now showing the blade as it is now.

-

08-18-2014, 01:14 AM #13Junior Member

- Join Date

- Aug 2014

- Location

- United States

- Posts

- 9

Thanked: 0

By the way, thanks to all for all the comments and suggestions! I've read every one, and if it looks like this isn't returnable or that I can't fix it myself, then I'll certainly try sending it off to one of the pro honers.

-

08-18-2014, 01:23 AM #14

All we can do is give suggestions my friend.

It is almost impossible to give 100% accurate advice based on pictures.

One would need to have it in their hands to KNOW what is going on.

If you in FACT know "that the flat spot was caused by me honing too far over onto the heel, and that simply is not so." ...

then I can offer no more suggestions.

Ed

-

08-18-2014, 01:25 AM #15

-

08-18-2014, 01:36 AM #16Member

- Join Date

- Aug 2010

- Location

- Rochester, NY

- Posts

- 71

Thanked: 14

Think of it this way: if you ride your car onto a curb, do your tires wear evenly? Of course not. Where the tire is on the curb, you will see more wear. There will also be a gap where you see no wear at all. The bottom of the tread will also be worn. The enlarged images only outline what the others have told you. You honed onto the stabilizer which has changed the original honing angle just enough to create the flat spot that has the "original grind marks." I did the same to many razors before I realized what not to do. The advice being given is exactly correct.

-

08-18-2014, 01:54 AM #17

Sethbag,

I see you're in the United States. So am I. Just drop over and I'll help you get that straightened out.

If you post your location, there is likely someone nearby who can help.

-

08-18-2014, 02:00 AM #18

Seth,

We haven't seen the other side of the blade. That can tell a story or finish telling the story.

On the opposite side, does the bevel widen on that side directly opposite of the spot you've indicated. i.e. Is the opposite side bevel even from the heel and on past the spot or does it widen at that spot and is narrower before and after.

If it widens directly opposite of the side we see, then you're probably dealing with a warp in the blade. If the other side is a consistent width bevel even through that area, then you're probably dealing with a grind issue.....the side you show got a little too much grinding in that one spot.

Either are not uncommon and can be honed to a good edge. The trouble you're facing now is that you've honed without tape on the spine and now have uneven wear on the spine. Also you've honed into the stabilizer and that's going to create issues too.

The razor can be corrected, but I strongly urge you to send it to a pro honer. You can find one in this link. You can contact them via PM or through their info supplied in their ad. They are very capable and they can get you back on the right road.

Member Services - Straight Razor Place Classifieds

Best Regards,

Howard

Last edited by SirStropalot; 08-18-2014 at 04:43 AM. Reason: Contact info

-

08-18-2014, 06:15 AM #19Junior Member

- Join Date

- Aug 2014

- Location

- United States

- Posts

- 9

Thanked: 0

I appreciate your comments. I'd only like to point out that if that flat spot was such because I'd lifted the heel end and thus not honed that spot, it would be a high spot, not a low spot. It's clearly a low spot, as is easy to see with a loupe, and as I think is clear from the photos I posted. See photos 2 and 3 in my original post. They show a clear low spot in the blade.

After reading, and re-reading, all of you guys posts, and considering the idea I proposed in my previous post, I decided to try to hone the side with the low spot until the edge wore down in the direction of the other side of the blade, and a slim bevel appeared. Once I had a continuous bevel on the problem side, I worked up through my 8k and 15k stones and stropped the razor on my new SRD long english bridle strop (just received it).

I tried shaving with the razor on my weekend beard growth. I only did half my face. It did in fact shave the face, but not nearly as easily as my Feather does, especially the areas I still struggle with, such as the chin. I'm not there yet. I'll re-watch all the honing and stropping videos, re-read the FAQs and articles and whatnot, and then revisit the edge again.

Here's the razor again with a thin but presumably usable bevel through the flat spot

-

08-18-2014, 06:31 AM #20Junior Member

- Join Date

- Aug 2014

- Location

- United States

- Posts

- 9

Thanked: 0

Yeah, I wish I'd taped this one, and rest assured I'll tape it in the future, and any future razors I buy too.

There's a good chance I'll end up doing that. One thing is I'm the kind of guy who expects myself to learn how to do these kinds of things and not rely on others. I already had some waterstones (though don't tell my wife, I went out and picked up the shapton 15k just for this razor) because of my woodworking experience, and I assumed that my sharpening experience with knives, gouges, and plane irons would mean I would learn razor honing quicker than average. I may be off-base in that assumption, but I will figure this out.The razor can be corrected, but I strongly urge you to send it to a pro honer. You can find one in this link. You can contact them via PM or through their info supplied in their ad. They are very capable and they can get you back on the right road.

Member Services - Straight Razor Place Classifieds

My view is that if tens of millions of average Joes throughout the world a hundred years ago managed to keep their razors shavable, it's something I'll get down eventually too.

I live in Arizona (about an hour southeast of Phoenix), in case anyone here lives close by and wouldn't mind showing a newb the ropes.

For now I'm trying to master sharpening the Dovo straight razor, and I'm willing to take my time. I've been shaving with the Feather for a couple months now. Each time I try the Dovo and it turns out not to be shave-ready yet, I just re-lather and kill the beard with the Feather straight razor. The Feather is unbelievable.

Thanks!Best Regards,

Howard

31Likes

31Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote