Results 1 to 10 of 14

Thread: Kamisori steel choice?

-

10-24-2014, 05:18 PM #1Senior Member

- Join Date

- Jun 2014

- Location

- CT

- Posts

- 229

Thanked: 25 Kamisori steel choice?

Kamisori steel choice?

In Japanese Kitchen knives, I love Blue and Super Blue steels. I am looking at getting my first Kamisori from Kanenaga. The place will be getting blue #2 and White #3 (I've seen Yellow #3, but not white #3? and this maker normally works in Yellow steel, not white from what I have seen??). Any thoughts steel wise which to get? I think there is around $40 difference in price with the Blue #2 being more expensive. I guess White would take the finest edge compared to blue, but not sure how the Yellow fits in? I know yellow has less carbon, but is Yellow finer grained than blue? I am kind of leaning towards the White #2 first choice (if it is in fact white and not yellow) and then Blue over the Yellow? Sound right?

-

10-24-2014, 05:34 PM #2

I'm certainly no expert in Japanese steel grading, but I understand Blue with lower numbers should be hardest. As opposed to other knife blades, we can abide a bit more hardness in our razors as the necessity for elasticity takes a second place to the ability to take a fine edge. With this in mind, I think I'd splurge on the Blue (No. 1 or Super, if available).

On a side note, I have some tamahagane steel razors that are allegedly in the vicinity of 67 on the Rockwell scale that have the ability to flex with minimal thumbnail pressure along the edge and immediately resume shape. Amazing stuff, and these are the qualities of the Japanese color system steels that I'm not familiar with that may impact which of these steels would be best suited for a kamisori...

!! Enjoy the exquisite taste sharpening sharpening taste exquisite smooth. Please taste the taste enough to ride cutlery.

!! Enjoy the exquisite taste sharpening sharpening taste exquisite smooth. Please taste the taste enough to ride cutlery.

Mike

-

The Following 2 Users Say Thank You to entropy1049 For This Useful Post:

KindestCutOfAll (10-30-2014), markbignosekelly (10-24-2014)

-

10-24-2014, 05:42 PM #3Senior Member

- Join Date

- Jun 2014

- Location

- CT

- Posts

- 229

Thanked: 25

Yeah, I've seen the steel do some neat stuff like that in kitchen knives and thin thin thin tips flexing back and forth and coming back to straight numerous times! I know White is finer grained and can get very hard and blue has more alloying elements to it, I wasn't sure if the alloying elements would make the grain size significantly larger and impede getting a smooth, close shave? The place also has a White #1 Itto Ryu Kamisori, too.

-

10-24-2014, 06:12 PM #4Senior Member

- Join Date

- Dec 2012

- Location

- Egham, a little town just outside London.

- Posts

- 3,857

- Blog Entries

- 2

Thanked: 1083

I can only say what I've read about two carbon steel types “White-2” and “Blue-2”, these give a HRC hardness of between 58-60 for “White-2” and 60+ HRC for “Blue-2”.

This hardness in practice makes little difference to the shave itself, the main practical difference is in the ease of maintenance - “White-2” will take an edge more easily but “Blue-2” should retain its edge longer.

You can always drop the vendor an email. Takeshi from Aframestokyo has always been extremely helpful when I've emailed him.Last edited by markbignosekelly; 10-24-2014 at 06:15 PM.

-

10-24-2014, 07:14 PM #5Senior Member

- Join Date

- Jun 2014

- Location

- CT

- Posts

- 229

Thanked: 25

Yeah, I'm not concerned about the hardness, I am concerned with the grain size/structure of the steel itself. I know Blue #2 has larger grain structure and carbides than White steels typically have, so it may not take as fine of an edge, but will hold the edge longer and has a touch more corrosion resistance, but is no where near a stainless steel. I am wondering if the Yellow steel would have a finer grain to it due to less alloying elements and if that would make a smoother edge vs the blue. I know White steels will take the finest edge because of the lack of alloying elements and Blue won't take quite as fine. I know going up to the crazy high grits, this may be more important than kitchen knives I usually use in Blue steels.

It's not from A Frames, and the vendor is fairly new at Kamisori's and usually just does the chefs knives. I wasn't sure if anyone had used the Blue #2 Kanenege Kamisori and/or the Yellow versions and has any insight with the different steels.

-

10-28-2014, 01:41 PM #6Senior Member

- Join Date

- Jun 2014

- Location

- CT

- Posts

- 229

Thanked: 25

Went with the Blue #2 and a Nakayama Koppa stone, too!

-

10-30-2014, 07:25 PM #7Senior Member

- Join Date

- Jun 2014

- Location

- CT

- Posts

- 229

Thanked: 25

-

10-30-2014, 07:35 PM #8It's bloodletting with style! - Jim

- Join Date

- Jul 2011

- Location

- ~ California, USA ~ The state of denial!!!

- Posts

- 615

Thanked: 118

Great information on steel grading.

May your lather be moist and slick, the sweep of your razor sure, and your edge always keen!

-

10-30-2014, 07:49 PM #9Senior Member

- Join Date

- Dec 2012

- Location

- Egham, a little town just outside London.

- Posts

- 3,857

- Blog Entries

- 2

Thanked: 1083

Found some good info at these sites

http://www.mehr-als-werkzeug.de/medi..._M_WE_D_en.pdf

Tamahagane SteelLast edited by markbignosekelly; 10-30-2014 at 07:52 PM.

-

10-30-2014, 08:50 PM #10Senior Member

- Join Date

- Dec 2012

- Location

- Egham, a little town just outside London.

- Posts

- 3,857

- Blog Entries

- 2

Thanked: 1083

I think you was right to go with the blue #2

Found some more info:

Yasuki steel

A Japanese steel derived from iron sand which is known to be traditionally used in the making of the nihonto. Hitachi metals used a similar iron sand to produce a material called Yasuki steel originating in the mountain ranges of China.

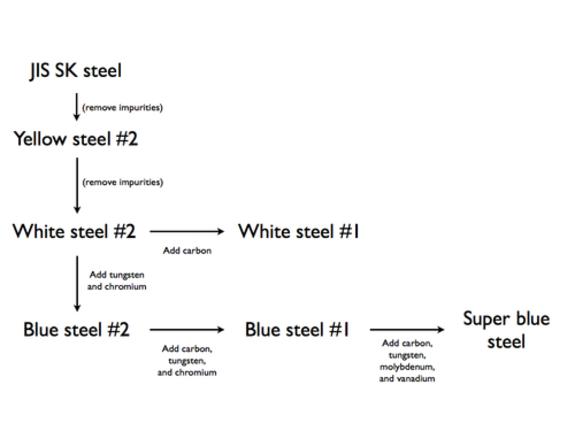

Yasuki steel can be divided into white, yellow, blue and silver.

White steel

100% iron sand, has a few impurities such as phosphorus & sulphur.

Yellow steel

50% iron sand. Contains much more impurities than white steel.

Blue steel

White steel mixed with chrome, tungsten & Carbon properties.

Silver steel

A type of stainless steel. Highly resistant to rust, but dulls rapidly.

White steel is traditionally said to create the sharpest blade. The more pure the carbon steel is, it is harder to work as a metal. Additionally, it must be cooled rapidly or it will not produce the true potential of hardness. As a metalsmith, it is a steel which becomes a show of skill level to work with.

Blue steel is white steel mixed with chrome & tungsten. The mixture improves workability, while the carbon helps it stay hard & sharp, its properties can be compared to new ceramic material.

Ratings of the Yasuki steel go from 1 to 3. 1 is hardest while 3 contains more impurities, however, 1 chips easier. The softest is 3 yellow Yasuki steel & hardest is super blue (one above 1 blue steel).

-

The Following User Says Thank You to markbignosekelly For This Useful Post:

Geezer (11-07-2014)

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote