Results 11 to 20 of 46

Thread: Is my near-wedge a near-wedge?

-

02-25-2015, 04:53 AM #11

Even 1/4 hollow in my book is still... hollow. I'm saying a 'true wedge' with completely flat sides does not exist outside of maybe a microtome. All razors, even the wedgiest-wedge you can find, were originally hollow ground in the sense that the only points of contact when laid flat are the edge and spine.

-

02-25-2015, 05:02 AM #12

I can't argue with you there. Even a microtome (at least the one I have) is only flat on one side.

I guess my original point is that I expected a Wacker near-wedge to be pretty close to the grind on this Wacker wedge:

(Photo from http://straightrazorpalace.com/razor...erfans-12.html)~Rob~

-

02-25-2015, 06:12 AM #13

-

02-25-2015, 07:34 AM #14

That's closer to being a near-hollow than a near-wedge. A near wedge, visually is obvious, and you'll not mistake it. Also, it will make very little sound when stropping and shaving.

-

02-25-2015, 03:49 PM #15Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

They do exist.

1. Loads of frameback blades are ground to be wedge like, especially swedish ones.

2. 'Rattlers are ground on the bottom section with the grinding wheel parallel to the spine, so the the bit below the hollow section under the shoulder of the spine is a true wedge shape, with no hollow whatsoever'.

Half rattlers - as above.

3. The classic Tuckmar "Tee" is ground with the the grinding blade parallel to the spine - no hollow to this one! It is a true wedge.

Thats a whole lot more wedges than "...they dont exist..." I am sure you will agree. The wedge shaped sides have been kept, but the honing angle has been ameliorated by using a spine atop it. Still all wedge-type blades, though.

I am not altogether sure that a wedge without the spine does not exist either. It takes but a fraction of a second to turn the blade round so it is ground with no hollow at all. Men, no matter what age they inhabited, have always been the most resourceful of the beasts, so why wouldn't they have turned out wedges?

Citing that grinding wheels are cylindrical is a bit short sighted and slightly nonsensical, as any point touching tangentially across the width of the wheel will be at an angle of 90 degrees to the centre and therefore straight as you like with no evidence of hollowing whatsoever.

In the end event none of us were there at the time and the blades that have come down to us from long ago have been reworked - eg hollow ground.

One other thing to ponder - no crazy no-use-at-all guesses allowed - Wade & Butcher blades sold as blanks with the legend "for concaving" on the tang. Straight (ie wedge) sides that needed hollow grinding? I don't think anyone knows for definite (definite meaning beyond all doubt, supported by documentary evidence).

Regards,

Neil

-

The Following 6 Users Say Thank You to Neil Miller For This Useful Post:

KindestCutOfAll (02-26-2015), onimaru55 (02-27-2015), Razorfeld (02-25-2015), ScienceGuy (02-25-2015), tedh75 (02-27-2015), WW243 (02-27-2015)

-

02-25-2015, 06:34 PM #16

I was not thinking along those lines and so left out the blades that have a honing guide, fair point. I did not know about the Tuckmar - interesting.

When making rattler-type grinds, would they still use the main surface of the stone, or the side of it?Citing that grinding wheels are cylindrical is a bit short sighted and slightly nonsensical, as any point touching tangentially across the width of the wheel will be at an angle of 90 degrees to the centre and therefore straight as you like with no evidence of hollowing whatsoever.

Thanks for the info.

-

02-26-2015, 05:02 PM #17Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

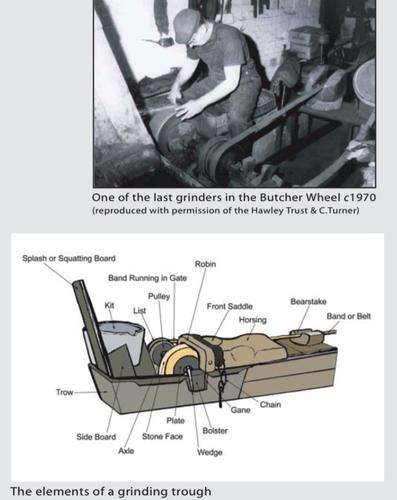

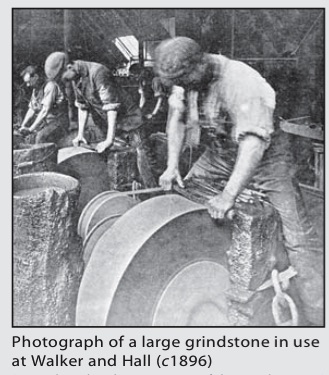

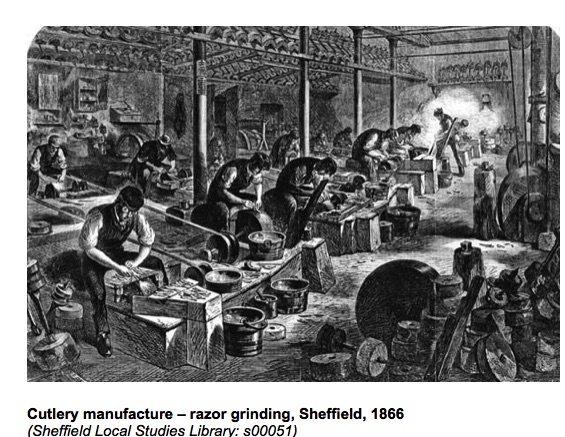

I would say that a professional grinder would never use the side of the hone. With the type of sandstone used for the wheels in Sheffield, the grinders were frequently injured by the stones flying apart in use, some were even killed, so I don't suppose they would even consider undermining the stone by grinding on the side of it.

Besides, some of these wheels were 36 inches, 48 inches, 60 inches and 84 inches in diameter. and 9 inches wide. 9 inches is a lot of real estate.

The grinders worked in a building called a mill, but this was regularly called a 'wheel' by locals, possibly because the oldest source of power for this sort of operation was a mill with a waterwheel attached - indeed, in the early days Sheffield's watercourses were dotted with watermills. The floor of each wheel was divided into a number of rooms called 'hulls' and in the grinders rooms there were depressions in the floor with either deep metal trays in them or they were lined with lead. These trays were called 'trows', a variant of trough. The wheel sat in this trow, which was filled with water unless dry grinding was necessary or wheel trimming, in which case the water was emptied and the whole hull was filled with billows of stone dust - giving rise to 'grinders lung' or silicosis.

Each sandstone wheel had a stub axle fitted, made from timber. and it was placed on supports like an axle, so it could turn freely. A housing was built around it, in stone or timber, then the sides were worked back in timber and a seating provided, saddle-like, for the grinder, to keep his butt out of the water. This affair was sometimes referred to as a horse.

Some Sheffield companies such as Herbert Robinson & Co even had this apparatus as a trademark:

Once you see the enormous size of the wheel you realise that it could never be easily mounted so that the side was used instead of the face.

Some trades, like pocket and penknife grinders had what look like a side-mounted wheel. On closer inspection the wheel (much smaller than those above) is indeed mounted in a cage with its stub axle vertical rather than horizontal, however the face was still used!

A long answer to a short question, to be sure!

Regards,

NeilLast edited by Neil Miller; 02-26-2015 at 05:28 PM. Reason: typos

-

-

02-26-2015, 09:19 PM #18

Mystery Solved!

Mystery Solved!

Last night, John Crowley of shavingshop.com saw this thread and emailed me to explain where the confusion lies. It turns out Herr Wacker made the "Old Sheffield" razor in two grinds: Keilschliff (near-wedge) and full hollow. While I assumed I had the Keilschliff, it turns out I have the hollow-ground version of the Old Sheffield.

Mystery solved.

Only now I want a near-wedge more than ever and John doesn't have any in stock.

So my search for a quality wedge continues.

My thanks to John for unravelling this enigma and taking the time to reach out to make sure I'm a satisfied customer. Indeed, I am!!!~Rob~

-

02-26-2015, 09:42 PM #19It's bloodletting with style! - Jim

- Join Date

- Jul 2011

- Location

- ~ California, USA ~ The state of denial!!!

- Posts

- 615

Thanked: 118

Great!, now I have to dig out all my Near Wedges, and that big W&B Frameback.

Well it's posts like this that makes me change up my rotation.May your lather be moist and slick, the sweep of your razor sure, and your edge always keen!

-

02-26-2015, 11:38 PM #20

73Likes

73Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote