Results 11 to 20 of 43

-

04-14-2015, 03:32 PM #11Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I am not sure at all about that.

Blister steel was made from wrought iron. In the cementation process, wrought iron rods were packed in ovens with sources of carbon (eg "cement powder") in alternate layers and heated for a week of more. This got more carbon into the steel, but it was not uniform - the surface had carbon rich blisters on it, but the carbon content fell off as the centre of the bar approached.

So it was broken up, heated and hammered to get a more even distribution of carbon and was then known as shear steel, which when properly done gave a wonderfully fine edge to edge tools etc. Sometimes the process of breaking up, heating and hammering was done again - to give Double Shear Steel. I think there was also a Triple Shear Steel.

Or the blister steel was used to make crucible steel (introduced in 1745 by Benjamin Huntsman in the UK and sold initially to the french market as Acier Fondu) a steel known as long ago as Medieval times in Asia, where it was called Wootz.

Note the date - 1745.

Crucible Steel was made in refineries with a large furnace holding a lot of clay pots or 'crucibles' - maybe 12 or so, each holding 15kg of product. The broken up blister steel along with a special flux was placed in the furnace when the pots were white hot and left for 3 hours or so, then poured into ingot moulds and cooled. This was large-scale production - you could go smaller, but there was a lot of work involved and skills that ordinary razor makers and razor grinders did not possess. The furnace had to go up ti 1600 degrees alone.

This product was also known as Cast Steel - because the crucible steel was cast into ingots.

It did not take off in Sheffield at first as the steel and Iron masters resented change, so Huntsman sold to the french. The products made from it flooded back into the UK, which frightened the Sheffield magnates, making them change their minds. Business soared. Practically all razors were made from this in the mid to late 1700s.

By the 1860s the Bessemer Converter produced steel very cheaply compared to other methods, so steel products became cheaper.

Regards,

Neil

-

-

04-14-2015, 03:43 PM #12Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

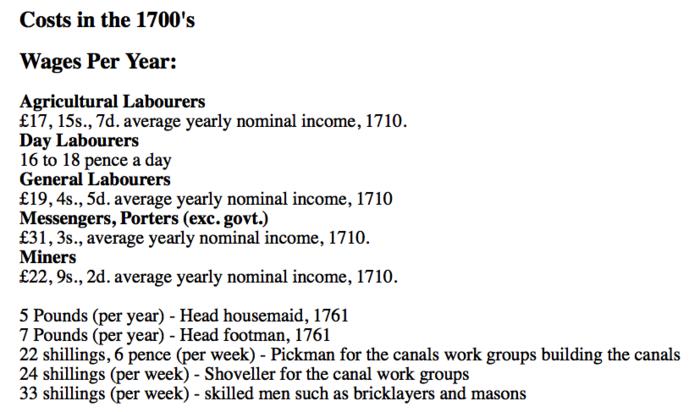

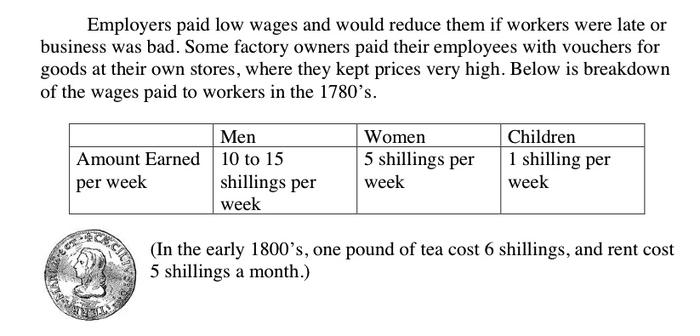

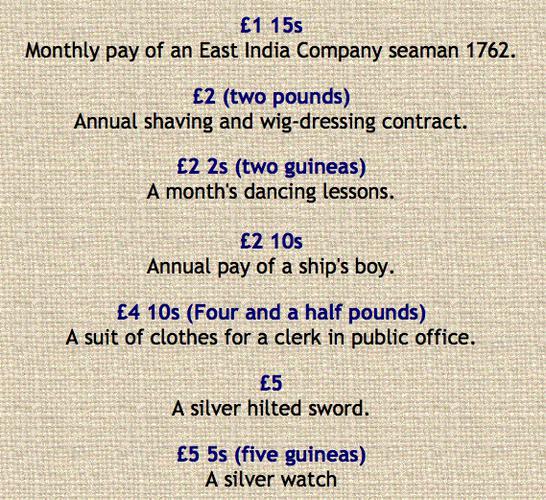

Prices from the 1700s seem not to have survived, though I suppose there must be lists somewhere. One way of going about hazarding a guess i by seeing how much people in that era were paid, and what other goods cost at the time:

The last image shows the cost of a sword. Not a common-or-garden sword, but one with a silver handle. The silver alone would be hefty and the steel used would be many times that in weight of a razor, so it is possibly reasonable to use this as a guide - could be a fifth, or less, or more - depends on the type of razor I expect.

If we use an average mans wages of 15 shillings a week ( a£pound is 20 shillings, then and now) he would have to work longer than a week to buy a razor.

However, pricing things then and now is often an impossibility. They did not have the same resources as us. They did not have mass-production methods like ours. Prices of what you can buy and what you earn do not help - they seem relative at first, but other factors present at the time prove the relativity to modern wages and costs to be vastly unsuitable.

Regards,

NeilLast edited by Neil Miller; 04-14-2015 at 04:11 PM.

-

The Following 7 Users Say Thank You to Neil Miller For This Useful Post:

CtwoHsix0h (04-17-2015), Frankenstein (04-17-2015), ggfinn (04-16-2015), Maximilian (04-14-2015), sharptonn (04-14-2015), tintin (04-14-2015), WW243 (04-14-2015)

-

04-14-2015, 04:12 PM #13

And there you have it! Thanks, Neil!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

04-14-2015, 04:14 PM #14

Was it the East India Company that had that "rum, sodomy and the lash" thing going for it? No, that was the English Navy I think......looking at those prices and wages, no way I could have gotten an IPhone being a ship's boy who took dancing lessons.

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

04-14-2015, 04:18 PM #15

-

The Following User Says Thank You to sharptonn For This Useful Post:

WW243 (04-14-2015)

-

04-14-2015, 05:18 PM #16Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

T'was indeed the Royal Navy, first uttered by Winston Churchill in 1913 when he was apointed First Lord of the Admiralty. The admirals did not like this appointment, and accused Winnie of impugning navy traditions, to which he replied "...and what are they? Rum, Sodomy and the Lash...".

Not that Winnie was the first - he based his saying on on much older sayings, like 'rum, bum and baccy'. Interesting, especially to those who enjoy multi-tasking.

Regards,

Neil

PS: and yes Bill, I can see you as a ships boy, but remember Treasure Island: "...those that dies'll be the lucky ones...". Aaargh!Last edited by Neil Miller; 04-14-2015 at 05:49 PM.

-

The Following User Says Thank You to Neil Miller For This Useful Post:

WW243 (04-14-2015)

-

04-14-2015, 05:37 PM #17

Niel,

What were the hardening and tempering methods? I have some older ±1800 razors that seem? to be "pack case hardened." A hard skin and a soft inner core. The edge is fine but is totally soft at the tip when honed That is the curve of the tip from long time of honing.

~Richard

Pack Case hardening here are some comments about the process and some ?:

Pack CarburizingBe yourself; everyone else is already taken.

- Oscar Wilde

-

04-14-2015, 06:17 PM #18Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I know that this process was used by razor cutlers, but they were not allowed to use it by the Cutlers Guild, which can be dated back to 1416 in London (The Worshipful Company of Cutlers) and the Company of Cutlers in Hallamshire, Sheffield, incorporated in 1623. Agents of the guild were permitted to go into the homes of little mesters and larger concerns to test and seize razors, knives etc.

Part of this was that inferior metal articles were not permitted. However, if you were not a member (freeman) of the guild, you did not have to abide by their rules, but then again you could not register your mark.

Case-hardening has its place - when I was a boy my grandfather used to do it.

I would also expect that early razors changed in the temper of metal as you progressed up the blade to the thicker bits like spine and tang, which are often softer. People who keep stating that very early razors were re-hollow ground in later times to suit the fashion often miss this point. You would need to re-temper as well, which means taking out of the scales, then grinding the scale off - cheaper to buy a new razor in my opinion.

It is not only early razors that exhibit this hard/soft anomaly: plenty of 1900 - to 1970 razors show it too.

Regards,

Neil

-

-

04-16-2015, 02:19 AM #19Junior Member

- Join Date

- Apr 2015

- Location

- Los Angeles, CA

- Posts

- 8

Thanked: 0

Here is the John Barber pre-guild mark (compass and square) stub.

There is very little wear on the tang. It has dirty translucent scales that look like wood until backlit.

Sorry about delay, had to wrestle with Ubuntu/Java a bit to make SRP upload features work.

-

04-16-2015, 02:30 AM #20

Man! That one looks really old.

"Don't be stubborn. You are missing out."

I rest my case.

62Likes

62Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote