Results 1 to 10 of 33

Thread: Custom Design - thoughts please

-

04-01-2016, 03:02 AM #1

Custom Design - thoughts please

Custom Design - thoughts please

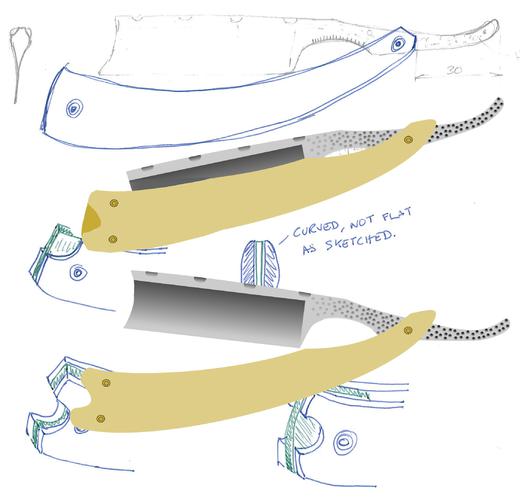

After reading the comments in the other thread where someone posted a custom razor design I thought "wow, these guys don't hold back!". Since I have thick skin, I thought I may as well post a similar request for comments on a design I have been working on. It is a work in progress, and there are some elements I am not sure about so it will be interesting to see what comes up. Here it is - fire away.

-

04-01-2016, 03:12 AM #2

Looks pretty neat. A couple questions.

What technique to put in the dimples?

Materials? Double check the forge. Might want to get a ref for a reliable metal source.

I think a less hollow grind would be easier for a first razor. Maybe a quarter hollow/near wedge?

-

04-01-2016, 03:21 AM #3

Dimples are just a quick and nasty was to show hammer finish. The hammer will fade as it gets to the shoulder as is shown, but it won't be round dimples.

I am not making this blade myself. I am working with a local expert for the smithing. I'm just coming up with the design. So steel I believe will be 80CrV2. Grind will be around half hollow. Blade finish to be polished. Scales to be Silky Oak, supplied by me. The timber is out of an old wardrobe that belonged to my in-laws way back when. Pins and wedge to be brass.

-

04-01-2016, 03:23 AM #4At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,105

- Blog Entries

- 1

Thanked: 13249

Form is always in the eye of the beholder so that is all up to you..

My only comment is about function

On the bottom two especially, the upturn of the pivot end of the scales, will actually push your thumb away from the tang and the Thumbnotch making those designs very awkward to strop...

Edit:

Just a suggestion, use O1 steel, razors are simple tools, and I have seen quite a few custom razors that don't hone or shave for crap made outta "Super Steels"Last edited by gssixgun; 04-01-2016 at 03:25 AM.

-

The Following User Says Thank You to gssixgun For This Useful Post:

Sxot (04-01-2016)

-

04-01-2016, 03:30 AM #5

Well, Mate, the spikey corners are NOT user-friendly and the dead straight-edge that looks like it is frowning is SO passe amongst those in the know. Those who make only that have no imagination outside of their box. Twice-pins on the wedge end is also nobueno!

Make a razor according to what works! YMMV

Make a razor according to what works! YMMV

There you have it!

Last edited by sharptonn; 04-01-2016 at 03:42 AM.

"Don't be stubborn. You are missing out."

I rest my case.

-

04-01-2016, 03:40 AM #6

I like the blade, slight smile might be nice...

Hammered finish will be sharp too.

-

The Following User Says Thank You to tab For This Useful Post:

Sxot (04-01-2016)

-

04-01-2016, 03:52 AM #7

-

04-01-2016, 03:53 AM #8

I'll consider a slight smile. All my razors (only 4) are all straight.

The current design is straight, no frown here.

-

04-01-2016, 04:13 AM #9

-

04-01-2016, 04:31 AM #10illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

Make the wedge an actual wedge. To me, nothing says lazy amateur more than a "wedge" that is straight.

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote