Results 1 to 10 of 11

-

04-07-2016, 04:13 PM #1Senior Member

- Join Date

- Jan 2015

- Location

- mountainside North Alabama

- Posts

- 129

Thanked: 14 ivo covrd tang - hmmm, how did they do it

ivo covrd tang - hmmm, how did they do it

I've been thinking about how the J Rodgers craftsman did this and am interested in others opinions.

I've been thinking about how the J Rodgers craftsman did this and am interested in others opinions.

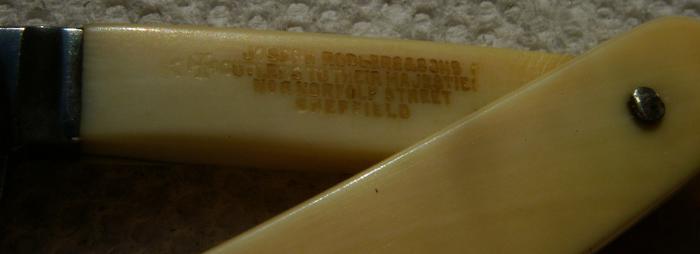

As for the Mfg Info - I think it was burned or seared in with a hot brand. Under the scope it looks like other samples I have where folks got crazy with the 'hot pin test.'

As for the tangway - I think the way was bored out with a round drill bit, then squared with a tiny scraper. I haven't thought of another way to put a rectangular hole in ivory- I imagine a flat, stiff wire with sharpened hook end. Not the best pic, but you can see the way is off-center. The tang is also off-center relative to the blade the same degree, so the craftsman skillfully squared the tangway to match.

Its a greater shaver. I've got a microfastener at pivot for now so I can take apart and inspect.

-

04-07-2016, 05:51 PM #2

I wish I could offer some help but I cannot. I always thought they were two piece with edges left at a 90 degree angle from filing to cover top and bottom of the tang, resulting in two L shaped pieces.

But I do believe I have read at some point that both knife makers and razor makers could indeed use a single piece of ivory for the tang very early on in razor and knife making. Perhaps burning was their process.

I am sure one of more knowledgeable members will help out here.Last edited by lz6; 04-07-2016 at 05:53 PM.

Bob

"God is a Havana smoker. I have seen his gray clouds" Gainsburg

-

04-07-2016, 07:05 PM #3

-

04-07-2016, 11:22 PM #4

Back in those days it was all done by hand and they had all the time in the world to do it. I have a razor with the tang covered in MOP. Probably a similar thing to yours.

No matter how many men you kill you can't kill your successor-Emperor Nero

-

04-08-2016, 09:39 AM #5Senior Member

- Join Date

- Jan 2015

- Location

- mountainside North Alabama

- Posts

- 129

Thanked: 14

BTW BigSpendur, I took your advice and got the Cape Cod polishing cloths for ivo and just like you said they give mirror polish. The product also claims to leave a protective film on metal- I wonder if you have taken advantage of this for razor steel or if it is formulated for silver ? It certainly turns a rag black on carbon steel and gives it a shine....

-

04-08-2016, 02:39 PM #6At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,031

- Blog Entries

- 1

Thanked: 13246

I have re-fashioned a couple of tangs using Acrylics and used exactly the process you assumed they used

I drilled a round hole then used Files to square it up and fit the tang, it is almost the exact same process you use when fitting a Rifle stock to an action.. Scrappers and Special Files and you slowly remove material until it fits

-

04-08-2016, 03:17 PM #7

I originally used them for polishing watch cases. They are really a Swiss Army Knife of polishers. They work on everything including straights though I wouldn't rely on it to impart a protective coating of any kind. They work better than any metal polish and if you spend the time with them you can really bring a dull razor bak to almost new looking condition.

No matter how many men you kill you can't kill your successor-Emperor Nero

-

The Following User Says Thank You to thebigspendur For This Useful Post:

KenG (04-08-2016)

-

04-08-2016, 08:46 PM #8

What is a cape cod polishing cloth? Or better yet , what's on them? Tc

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

04-08-2016, 09:29 PM #9

-

04-08-2016, 11:37 PM #10

They are pretty tight lipped about what's in them. A state secret I guess. Whatever it is it works.

No matter how many men you kill you can't kill your successor-Emperor Nero

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote