Results 31 to 40 of 46

Threaded View

-

09-03-2020, 09:11 PM #1

Titan Straight Razor Unboxing - Shave To Follow Tomorrow

Titan Straight Razor Unboxing - Shave To Follow Tomorrow

I just got my Titan razor yesterday. $30 USD. 10 days from order date from China via AliExpress. Fastest I ever got anything from Ali Express from China. I have friends in Japan that really like these Titan razors, so I had to finally try one. There are many styles you can find at the Titan store on AliExpress, and I just chose one at random. These are mostly hand made and hand honed razors that tout shave ready (as most all do), but my friends tell me theirs actually came shave ready. They have been to the actual Titan store(s) in China and were impressed by the quality and presentation of these razors and the ambiance of the store(s) in general. One told me that the store he was in made him think he was at the Ala Moana Mall in Waikiki, which is a very high end specialty store Mall.

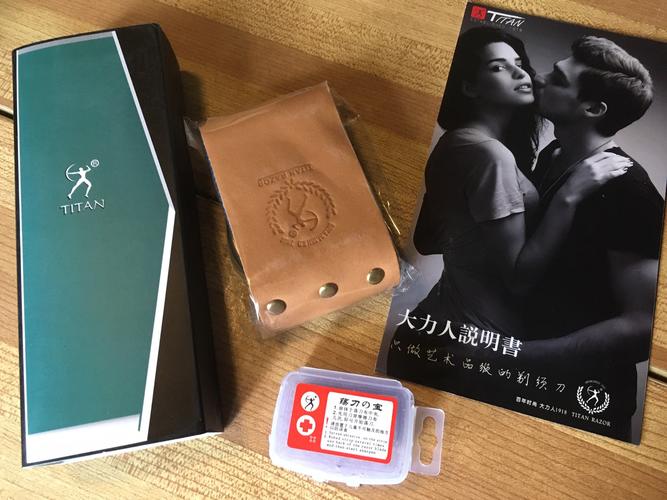

Here is the unboxing. Well packaged. Fooled me. I had ordered a power supply for my Chomebook and thought that's what I got so I didn't open the box yesterday or I would have shaved with this razor this morning. You get a small catalog-brochure, a small strop, strop wax (as they call it) and the razor in a genuine leather case. OK, so the strop is not something that most of us will ever use, but it is included so it's featured here.

Titan says that the razor is mostly hand made so there will be some irregularities from razor to razor with regard to scales. They like to use African Black Algum Mahogony and Copper or Mahogony and Copper. The Blade is wrought from VG-10hz to 59-61HRC.

The presentation is done very well and I have to say the leather case is very nice with chrome trim and a heavy duty vinyl zipper. You'd probably pay 30 bucks for just the case like this on Amazon, and another 20 bucks for the strop.

And Finally the RAZOR;

I will give this a finishing hone with my 12k stone and a stropping and do a shave tomorrow and follow-up to this.

Aloha!

-Zip"I get some lather and lather-up, then I get my razor and shave! Zip Zop, see that? My face Is ripped to shreads!"

113Likes

113Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote