Results 1 to 10 of 15

Thread: EBRO flee market razor

Hybrid View

-

05-25-2021, 07:29 PM #1

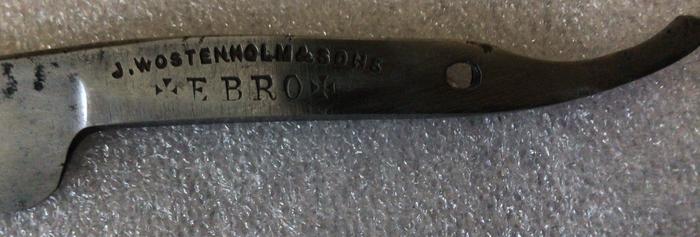

EBRO flee market razor

EBRO flee market razor

found this one this past Sunday for $1.00 the pivot was held together with blue painters tape.

And this one is from another few I picked up 2 weeks ago and thought it was the best of the bunch. I have just got a chance to try to clean it. it only had a small rust spot but turned out to be the worst one of them all.

-

05-25-2021, 09:38 PM #2

The first one will have pitting left even after some hand work. Unless you have a belt grinder. It could be made to shave.

The second one is going to loose a lot of heal to fix. It can be done. This is the problem with buying razors and not knowing what to look out for. We have all been there. Get to sanding!It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

Audels1 (05-25-2021)

-

05-25-2021, 09:45 PM #3

Both together cost the same as a coffee from DD so the loss would not be great. I do have a belt grinder but am more concerned about the pivot hole being elongated.

-

05-25-2021, 09:51 PM #4Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

I am no expert on how big is too big on the pivot hole, but there are ways to fix it. Use the advanced search to find more, but I just found this one.

https://sharprazorpalace.com/worksho...ml#post1453240

PS: Saw two links in Rezdog' post and just linked to his. One goes to GSSixgun's illustrated guide and the other goes to the workshop sticky library that references GSSixgun's illustrated guide. Oh well, must be good advice.Last edited by planeden; 05-25-2021 at 10:03 PM.

If you're wondering I'm probably being sarcastic.

-

The Following User Says Thank You to planeden For This Useful Post:

Audels1 (05-25-2021)

-

05-25-2021, 10:21 PM #5

Many razors still have an elogated hole. Even after restoring. My understanding it they were punched from each side and just were not lined up as well as they should have been. It doesnt move much in the scales but if your concerned about it you can leave a tiny bit more room in the scales to when it shifts it wont hit the wedge.

Or fill the hole with a piece of tubing the right size if you can. Solder the hole or used some soft metal of some type to fill and redrill. Lots of ways to skin a cat. Just don't tell my wife I said that.It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

Audels1 (05-25-2021)

-

05-27-2021, 03:48 AM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

No, belt sander!

Heat is a blade killer, just takes a second, literally.

A 1k diamond plate or 1k stone will reshape it just fine, and more importantly safely. You can buy a $30 1k /600 diamond file, that make this kind of work a snap and gives way better control. With a diamond file you can work with the edge up and remove just enough material and see exactly what you are doing.

Draw an arc with a sharpie and large coin or washer, so that you remove the least amount of steel. WD40 removes ink if you want to make a correction. Or a $30 CNTG 1k/400 diamond plate, or a 1k stone. The plate can be used to lap stones.

The scales may be saved with CA or epoxy, clean well first especially the joint. Sand smooth with 600 grit when dry. Save all the sanding dust and use as filler with CA or epoxy.

Glue together on a piece of waxed paper and flat surface, hold them together glue with CA and spray a kicker. Then build up a layer on inside and outside, with CA or epoxy with sanding dust, fill the hole and re-drill. Save all the sanding dust and use as filler with CA or epoxy.

CA is easier and quicker to work with.

The pivot hole is a non- issue and most probably has been like that since new. It will pin just fine, with just a 1/16th inch pin.

Take your time, do not rush and you can learn a lot from these kinds of repairs. As long as the steel is good you can make shavers from these kinds of projects.

Buy up all the cheap razors you can find and experiment with repairs and honing.

Horn is very forgiving, easy to work and finishes well with just sandpaper and any good metal polish.Last edited by Euclid440; 05-27-2021 at 04:08 AM.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Audels1 (05-27-2021)

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote