Results 31 to 40 of 46

-

09-02-2009, 08:16 PM #31

-

09-02-2009, 09:38 PM #32

This actually restarts an old topic but what you say here does not make any sense. How can you possibly think that by thickening up the spine with tape and decreasing the angle between the thickness of the spine and the cutting edge - that it will give you a finer edge. It just doesn't happen that way and the world is actually round - not flat

Taping the spine is like cutting all the rubber off one spot on a tire so that your car won't roll away when parked.

-

09-02-2009, 09:45 PM #33

"Aside from all the fuss, Pumas and Dorko's are nice looking razors, but edge retention? Maybe not all they are cracked up to be...."

You are kidding - right? Am I going to have to call you Shirley because you jest?

"The newest TI's ("hard" steel) have been reported by some to give a somewhat uncomfortable shave."

Whomever told you this needs to have his razors properly honed! Unless the grind is defective - i.e. ground deeper on one side than the other so that the edge doesn't touch the hone.

-

09-02-2009, 09:54 PM #34

"perhaps the issue is honing them and not the edge itself..."

Sounds like the answer to me! As for the W&B steel being soft at Rc58 - that isn't really that soft. A razor with a Rockwell 58 hardness should and will hold a good edge - if you put a good edge on it to begin with. There has been a lot of discussion in the past about how hard the Friodurs are to hone. I took one to a local foundry and had it tested and it was an Rc58 too! That is a hardness level that can be easily obtained in a "mass production" environment. Making a razor an Rc62 or so requires more skill and patience if you want to make sure it is tempered properly so that it isn't brittle.

-

09-02-2009, 10:08 PM #35

Speaking from experience there are many a tools out there in the manufacutring community that are 58Rc and cutting things much harder than whiskers for much longer than, being generous here, 90 shaves x 30 minutes = 2700 minutes, 45 hours.

As I stated, I have a bunch of Sheffield straights and all but one honed up and shaved just fine. How long do my edges last? Don't know and probably never will, but when they come up in rotation they shave fine and smooth.

Jim, I really enjoy reading your replies!“If you always do what you always did, you will always get what you always got.” (A. Einstein)

-

09-02-2009, 10:20 PM #36< Banned User >

- Join Date

- Feb 2008

- Posts

- 3,763

Thanked: 735

-

09-02-2009, 10:40 PM #37At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,039

- Blog Entries

- 1

Thanked: 13249

Actually there seems to be some historical precedent to a lifted spine, even a device to lift the spine to hone true wedges, we are still looking for definite proof but the evidence is a little compelling...

That aside, there is another reason for 1 layer of tape when honing these oldies, imagine a rutted old road (the spine) and every time you try to drive down (hone) the road (the edge) you keep getting pulled into the same old ruts...

Now along comes a road grater (1 layer of tape) and smooths the road (the spine) which now makes it much easier to steer clear of the obstacles in the road....

I never advise more than one layer unless you are doing serious restoration but on these razors it helps get a good even bevel going ...

-

09-02-2009, 10:49 PM #38

Hi John,

Please don't put words in my mouth. I did not say finer edge. It would be a little more obtuse so a little stronger. Definition of a good edge is to make an angle as fine as possible without deterioration. The OP was how they don't hold up as well as others. It works for me.

M

-

09-02-2009, 11:29 PM #39Coticule researcher

- Join Date

- Jan 2008

- Location

- Belgium

- Posts

- 1,872

Thanked: 1212

I don't comprehend that statement.

Taping the spine makes it slightly thicker. The resulting bevel has an angle that is slightly more obtuse. If we would compare the cross-section of both bevels, we would notice that the one cut with the thicker spine has a slightly wider base. Whether the difference of one layer is enough to make the edge more durable in a significant way, is something I highly doubt. (I believe we agree about that).

Yet I measure the bevel angle on every wedge I hone. And I have honed my share of poorly shaving wedges previously honed people that otherwise have no problem putting a good edge on a razor. In several cases the bevel angle was clearly out of range (under 15 or over 19 degrees) Correcting that, by adding, or alternatively not adding, tape always made a pleasant improvement.

I have seen wedges that were honed with at least 3 layers of tape and then convexed on a pasted strop (which only makes the angle even more obtuse), that should have in fact been honed with no, or maximum 1 layer. I have also seen wedges that had bevel angles of 12 degrees, and actually need 3 layers of tape to fall within range.

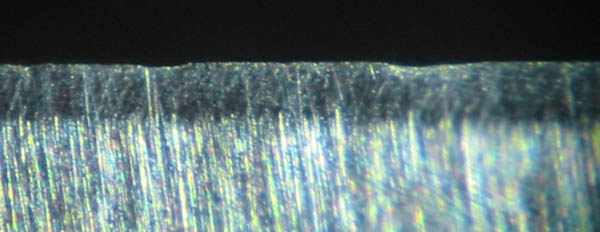

A bevel angle of 12 degrees easily wrinkles up during the shave. Let's see if I can find that picture back...

It's a "Sheffield Best" wedge, honed with one layer of tape, bevel angle approx. 12 degrees, edge deterioration after one shave. Please take my word for it, that the edge was perfectly straight before that shave.

An edge with a bevel angle of 20 degrees is so uncomfortable that it needs very high keenness not to pull on the whiskers. At the first signs of dulling it starts pulling heavily.

That is exactly my experience. Take the TI Silverwing. Allegedly very hard steel. But shaves like a dream if honed well. But I do not find it particularly having better edge retention that a razor of normal hardness. My beard easily causes microchips in the edge of a very hard razor. I think that's due to brittleness.

+1! I fully agreed.

A final question if I may: Is the purpose of tempering not to bring the RC down to a level that is considered acceptable as being hard enough to be stiff, but not so hard that the steel becomes too brittle for its purpose? So would tempering a hardened alloy that starts out at RC62, not be RC60 or so once it is properly tempered? Or doesn't it work that way?

Best regards,

Bart.

-

09-03-2009, 01:24 AM #40

"A final question if I may: Is the purpose of tempering not to bring the RC down to a level that is considered acceptable as being hard enough to be stiff, but not so hard that the steel becomes too brittle for its purpose? So would tempering a hardened alloy that starts out at RC62, not be RC60 or so once it is properly tempered? Or doesn't it work that way?

Best regards,

Bart. "

The stiffness of steel is directly related to thickness. two pieces of equal thickness require the same force to bend R62 or R42.

If you're asking something different it is unclear.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote