Results 11 to 17 of 17

-

11-24-2009, 06:31 PM #11

Just a note for anyone who does not know. Any razor, or knife for that matter, which is stamped 440 stainless is poor quality. If it were 440 C it would certainly be stamped that. There is no comparison between 440 and 440C. I once bought a large quantity of 440A stainless before I knew better,and it was not worth anything. It would not heat treat above Rockwell 54 I ended up using it for decorative parts. I saw a razor at the flea market last week marked as 440 stainless and the guy selling it said "look here, it is 440 steel". Mack

Last edited by mackie; 11-24-2009 at 06:37 PM.

-

11-24-2009, 06:37 PM #12

Do a little research on toughness of human hair, combine that with the actual thickness of razor edges and the mechanical stress they have to endure during shaving, and you will end up with non-trivial demands on quality of steel needed for good razors.

"A little stubble" gives zeepaks more than little trouble for sure.

-

11-24-2009, 06:38 PM #13< Banned User >

- Join Date

- Feb 2008

- Posts

- 3,763

Thanked: 735

-

11-25-2009, 02:45 PM #14Senior Member

- Join Date

- Aug 2009

- Location

- New England

- Posts

- 267

Thanked: 21

I prefer Sheffield steel

-

11-25-2009, 03:34 PM #15< Banned User >

- Join Date

- Feb 2008

- Posts

- 3,763

Thanked: 735

-

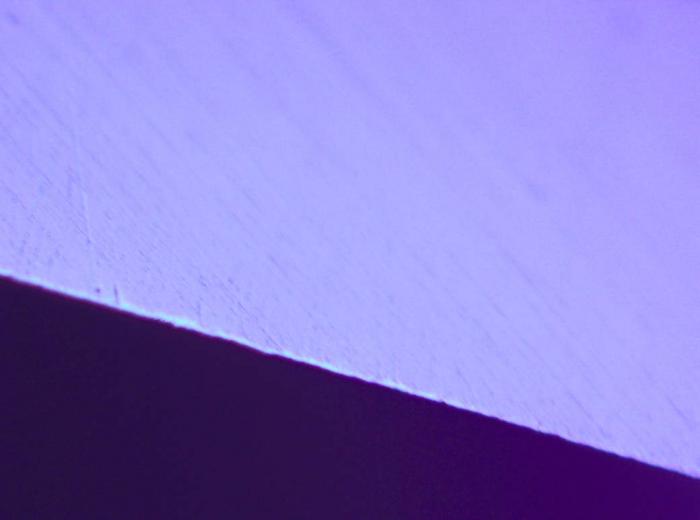

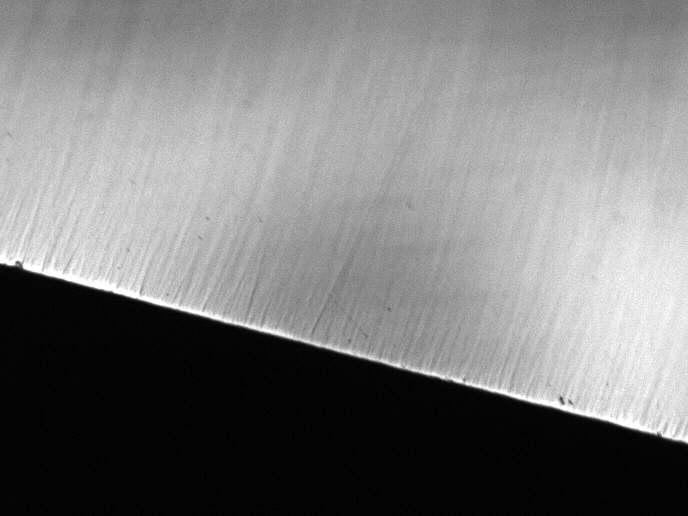

The Following User Says Thank You to Seraphim For This Useful Post:

ChayesFSS (11-25-2009)

-

11-25-2009, 03:35 PM #16Senior Member

- Join Date

- Aug 2009

- Location

- New England

- Posts

- 267

Thanked: 21

Great picture! Sheffield just feels softer on my skin, Stainless is somewhat harsh imho.

-

11-25-2009, 05:03 PM #17

A friend of mine sold a Chandler custom stainless wedge to me because he thought it felt harsh. He is quite a good honer so I didn't have to change anything and the razor has felt smooth as silk to me after many shaves. Never retouched it yet. I guess it is a difference in skin/whisker type ? I have a number of stainless razors both new and vintage and they all are fine with me. I love old Sheffield steel too BTW.

Be careful how you treat people on your way up, you may meet them again on your way back down.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote