Results 1 to 3 of 3

Thread: Coffin Box Deconstructed

-

02-09-2011, 07:44 PM #1Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164 Coffin Box Deconstructed

Coffin Box Deconstructed

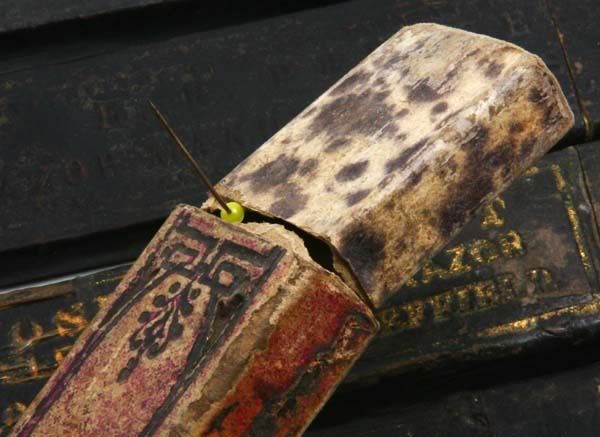

After reading a previous post by Henryjoe, I was reminded of an earlier discussion from 2008 in which I thought that papier mache might be used over a former to make these boxes. I have since changed my mind as clearly a form of pre-made rough paper was used instead of a pulp.

I have quite a few of these coffins and you can clearly see the form of manufacture in some of them.

The outer covering seems to have been a thinner, finer quality paper than the rest of the box was made from. This was wound over a previously wound strip of paper, made from quite rough card.

Inside this is a central core of rolled paper, of the same material as the layer immediately on top of it.

This open-ended core was - I think! - a strip of rough card, soaked in hot water to make it pliable, and wound over a core of shaped timber, probably hardwood, possibly even metal. At the top a thin layer of coloured paper was wound, this would show when the case was opened, and it was probably waxed or treated with something to stop it sticking to the other layers that would be placed over it.

Once this was in position strips of soaked card were wrapped over the whole former and smoothed down. On top of this was some sort of water-soluble adhesive - I could feel its dried granulated form when I unwound the coffin. It was a bit like the old-fashioned rabbit-skin glue old carpenters used which becomes dry and crusty with time, and the granules dissoved in the hot water I was soaking the coffin in.

Then the final fine paper covering was wrapped over all and the edges smoothed down. For the decoration, two metal plates must have been engraved, and somehow these were clamped to the bundle just formed. You can see the paper seams running under the embossed lines, which shows the sequence of events. If the plates were heated, this would dry the coffin shell very quickly, perhaps doing away with the need of clamping the engraved plates in place - enough force for the design to be deeply imprinted could have been exerted by a simple screw press which held the plates in carriers, or even by welding the plates to a pair of stout, long-handled tongs.

The last mechanical process would have been cutting through the coffins outer layer at the change of taper in the former - it would have to be carefully cut and some were not - the one I soaked showed cut marks nearly all the way through in places, and the pink Wade, Wingfield & Rowbotham box has similar cut marks at this juncture. This is where the wax on the covering of coloured paper would prove its worth - any glue that found its way out of the card pulp or from under the fine layer would have stuck what is now the top of the box on fast.

Just the colouring remains. What it was I cannot say - it is slightly water repellent, and may have been some early cellulose 'dope' varnish or something similar with pitch in it. An optional gilding and the box was ready.

I can't really see all these processes being done in the factory. Like polishing, it was probably done by women and children, and most likely - given the methods of working in Sheffield at the time - at home.

Regards,

Neil

-

The Following 13 Users Say Thank You to Neil Miller For This Useful Post:

AlanII (02-11-2011), AntiqueHoosier (02-09-2011), BrickBag (02-10-2011), FatboySlim (02-11-2011), ignatz (02-09-2011), MODINE (02-09-2011), MW76 (08-02-2016), nzFuzzy (02-09-2011), Oldnick (03-12-2016), Sailor (02-09-2011), Snake (02-10-2011), timberrr59 (02-09-2011), Walt (02-10-2011)

-

02-09-2011, 09:12 PM #2

Neil;

The process you describe makes perfect sense. I suppose that they would have used something like simple wheat paste for the internal wrappings and, yes, I agree, a classic, hot animal glue to seal the outside.

As you so rightly point out, this was probably the domain of cottage industry. Seeing this little bit makes me wish for more information.

Thank you very much for this insightful write-up. I very much appreciate you sacrificing one of your coffin boxes to further our general knowledge.

- Ignatz

-

02-10-2011, 06:02 PM #3Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

Thanks Ignatz!

The more I read about this method of construction, the more likely it seems that you are correct about cooked wheat paste being used as a binder/glue for the wrappings.

I would dearly like to know more about this side or cottage industry, too, but despite trying hard over a number of years I have yet to find anything definitive.

One lead I did pick up was about making small boxes (pill boxes, snuff boxes and so on) out of card, assembled in the same manner as the coffin boxes. The finish was to resemble black japanned ware, and several spirit varnishes were used. The black ones either contained a pigment like lamp black dissolved in a resinous gum such as copal and thinned with turpentine or white spirit. Coach-builders used the same recipe, but substituted the finest grade pitch or asphalt for the pigment, but I suppose that the coffin boxes used a much cheaper alternative like Brunswick Black which was hard pitch dissolved in spirits.

The 'gilded' lettering was done by finely grinding a cheap alloy - dutch metal (also known as dutch gold) and adding it to a resin, then painting it on. Much cheaper and quicker than proper gilding.

Regards,

Neil

-

The Following User Says Thank You to Neil Miller For This Useful Post:

AlanII (02-11-2011)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote