Results 1 to 10 of 11

Thread: restoration advice

-

04-12-2012, 05:05 PM #1Junior Member

- Join Date

- Feb 2012

- Location

- middle Tennessee

- Posts

- 7

Thanked: 0 restoration advice

restoration advice

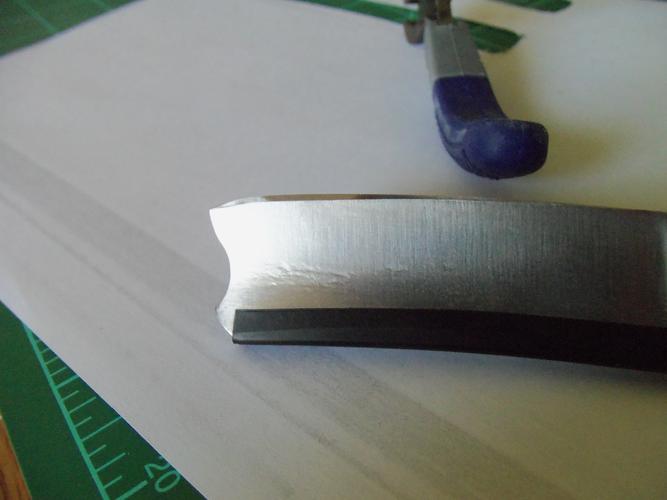

i recently acquired a wade and butcher from ebay. i discovered that the blade is warped or perhaps a bad grind. i am wanting to know if there is any use in continuing to try to get a good edge. i have a couple of pics that i will post. i am very new to straight all together. i have a norton 4k/8k that is what i am working with. the blade is 1 inch wide. huge to me. so any advice that anyone could give would be greatly appreciated. i do have an edge that will shave but it is not on the entire length of the blade. short of pivoting to blade while honing i am at a stand still.

not sure about uploading pics on here. i hope you can see them well enough.

not sure about uploading pics on here. i hope you can see them well enough.

-

04-12-2012, 05:17 PM #2Poor Fit

- Join Date

- May 2010

- Posts

- 4,562

Thanked: 1263

Hard to tell from the pics but that blade doesn't look bad at all. Maybe try rolling x strokes to make full contact on the hone with the entire edge. The magig marker trick will help you out there as well.

-

04-12-2012, 07:54 PM #3Junior Member

- Join Date

- Feb 2012

- Location

- middle Tennessee

- Posts

- 7

Thanked: 0

i don't know if the pics are good enough but if you look closely you can see it kind of looks like a wave the toe end looks to be more center and the heal end is off center. i have tried all the different strokes and still the spine is is showing wear in two different places so i have adjusted to try and set the bevel in between the two. but it looks like it is going to take a lot of grinding or perhaps a more aggressive stone. just kind of wondering if anyone had encountered this type of problem before and if it was worth pursuing. it is a very old razor and i do not usually run across these on ebay so i was thinking it was probably one that should have been discarded long ago. i am just trying to make the most of it. thanks...

-

04-12-2012, 08:56 PM #4

I can't see the wear on the spine , because of the tape . If you can post some pics of the wear on the spine , both sides , I might be able to tell if you have a bowed spine . If the blade is badly bowed , it's probably not worth the effort . It will take a month of Sundays to hone the bow out of it , and when you're done you won't have much of a razor left . However , if the bow is very slight , a little time on a 1k might fix it .

-

04-12-2012, 10:33 PM #5

well i think more time of the lower grits might help. but i am lazy, if it were mine i would send it out to be honed

-

04-15-2012, 02:00 PM #6Junior Member

- Join Date

- Feb 2012

- Location

- middle Tennessee

- Posts

- 7

Thanked: 0 wade and buther 6/8 for barbers use

wade and buther 6/8 for barbers use

here is a couple more pics of the blade. i can't seem to get a good picture for you to see exactly what is going on but the blade looks like a wave. at one end it is nice and centered on the spine but on the other end it (the point ) is off to one side. in one picture you can see that, while resting on one side spine flat the entire blade is touching. when turned over to the other side, with the spine flat only the toe end of the blade is touching. i can make the heel end touch the stone but in order to do that i have to hold the toe end of the spine up off the stone. so my big question for the pro's is do i have to try to find a middle ground and then a lot of grinding on that side to (set the bevel) or am i just wasting my time? any advice is appreciated.

-

04-15-2012, 02:45 PM #7

-

04-15-2012, 02:59 PM #8

I believe that grind was near perfect, before the 100+ years of use and 1/8" of bevel wear

As long as you are using x stroke dont be concerned about an uneven bevel wear. There is a good possibility the grind is thicker and thinner naturally at that point of the blade, I suspect the grinder was more concerned with the edge.

As long as you are using x stroke dont be concerned about an uneven bevel wear. There is a good possibility the grind is thicker and thinner naturally at that point of the blade, I suspect the grinder was more concerned with the edge.

On a smiling blade you could rarely if ever expect the blade to lay flat and contact the hone/ cutting board, thats the reason for the rolling x.

Also worth noting your razor is growing quite the spur at the heel, personally I would address that before continuing.

Good luck!

-

04-15-2012, 03:05 PM #9Member

- Join Date

- Feb 2012

- Location

- Ann Arbor, Michigan, United States

- Posts

- 74

Thanked: 16

I would just say go for it. With that much metal I would just say go for it.

-

04-17-2012, 12:23 AM #10Junior Member

- Join Date

- Feb 2012

- Location

- middle Tennessee

- Posts

- 7

Thanked: 0

first off. thank you for your advice. i have now read through the FAQ's and the section on honing. i will give it another go. how should i address the spur that is starting to appear? and thanks again for all of your advice..Brian

3Likes

3Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote