Results 1 to 10 of 12

-

05-20-2012, 09:41 AM #1Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

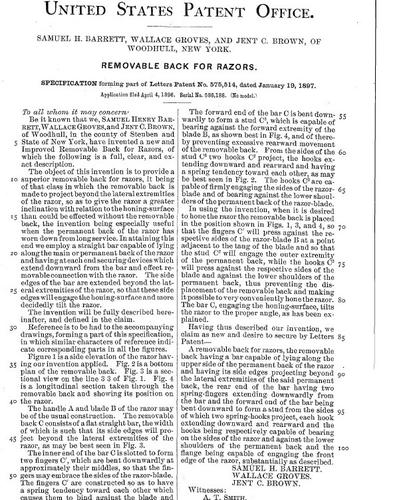

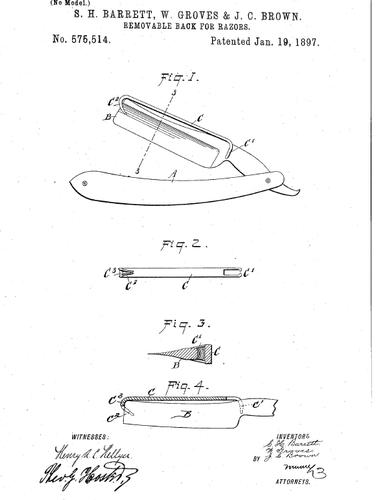

Thanked: 4249 Interesting patent removable back razor.

Interesting patent removable back razor.

Anybody ever came across one of these?

-

05-20-2012, 10:12 AM #2

A variation on a theme. Instead of a replaceable blade you have a replaceable spine. It doesn't seem very practical and my guess is that it never went into any kind of serious production. Like a lot of patents, it looks good on paper but doesn't translate into a marketable design.

Regards - Walt

-

05-20-2012, 10:21 AM #3

I have a small one from Eskiltuna that's based on that concept.

I haven't honed it yet but it looks like a decent razor.

-

05-20-2012, 10:24 AM #4Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

-

05-20-2012, 10:48 AM #5

-

05-20-2012, 11:01 AM #6

-

05-20-2012, 11:12 AM #7Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

-

05-20-2012, 11:23 AM #8

After reading the sections this week on the use of TAPE in honing I'm glade to see that the debate has probably gone back to the beginning of Straight Edges. The idea of a removable bar if it could be made to move from razor to razor sounds like it logical solution if it could be made to stay on and adjustable for the geometry of different razors.

-

05-20-2012, 11:38 AM #9

From what I know the reasons for these tubes where to simplify the production, the blade and tang where made out of one piece of steel, therefore you will see that most of the Swedish razors with this patent got a equally thick blade and tang, and the "spinetube" was made of a softer metal.

So for the tape/no tape discussion: Razors of this kind should be honed with tape as the spine will wear down significant faster than the blade

I guess back in the days when these where made that you could get a replacement spinetube, but I don't recall seeing any now.

-

05-20-2012, 04:14 PM #10"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

And to include Zephyr's comment about simplifying production... both answers are yes. Once of the first items a blademaker would notice is the lack of weight at the spine. This allows a thinner blade to be useful for shaving because the softer/harder tubing/spring device allows the correct angle for honing when the spine of the blade will not deliver it. It's also much easier to do a flat grind on a thin piece so there would be no need for a variety of diameters to get the hollow grinding right. Less tooling equals money savings on the factory floor and in speed of production.

That might also translate into a lighter razor and tailor to the end-user's preference but that's a guess on my part. It would be useful to see some company advertising to know if they used it that way.

From a simple production perspective, a thinner piece of steel means that less of the good steel is wasted on non-cutting edge parts of the blade. With a thin spine being supported by a much less expensive piece of support material, potentially means more per volume per pound steel available for making more razors and more profit for the company. Each element of production savings means more at the bottom line.

Other ideas that free float in my head this morning are that it may be possible to adjust the spine support to help recover from some edge warpage. A straight spine tube or spring would provide a guide to correct a problem like that if the razor was then "adjustable" to good enough. Less razors tossed in the scrap means more sold out the door.

Hopefully these are useful suppositions..

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote