Results 1 to 10 of 10

11Likes

11Likes

Thread: The Aluminum Steel Razor

Hybrid View

-

02-05-2013, 02:02 PM #1Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

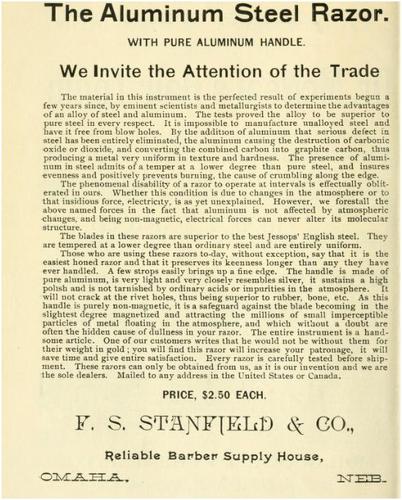

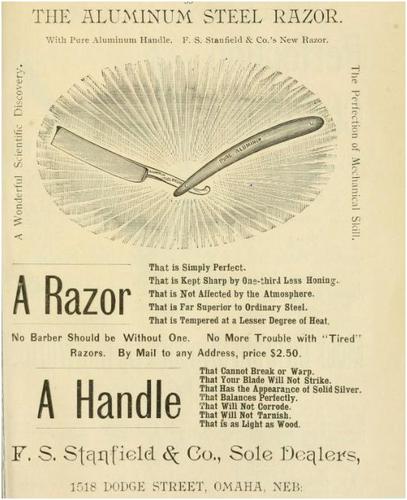

Thanked: 4249 The Aluminum Steel Razor

The Aluminum Steel Razor

The Aluminum Steel Razor from F. S. Stanfield & co Omaha Neb.

-

02-05-2013, 05:01 PM #2

Since you simply don't see any such razors on the market that pretty much tells you how successful this was.

No matter how many men you kill you can't kill your successor-Emperor Nero

-

02-05-2013, 08:40 PM #3Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

Although Humphrey Davy first postulated the existence of aluminium in 1807 (it was found only as a salt before), it wasn't until 1825 that the first metal was produced, although only in very small amounts. It wasn't until 1854 that kilos of it could be produced - at very high cost. In 1885 it was exhibited at the Exposition Universelle in Paris, and the Emperor Napoleon gave a huge banquet where the most honoured guests had cutlery made from aluminium while lesser guests had to put up with solid gold cutlery. That gives some idea of it's original value. In 1886 a more efficient process was found and in 1888 this was improved on and the price of the metal came crashing down.

In 1895 Napoleon le Blanc recommended the Stanfield razor in his Essay on Barbers' Razors & Honing

Steel has been alloyed with aluminium for a long time - it removes gases, makes the grain finer and improves strength - so in this respect it was pretty much successful. As a steel alloying agent, it is used in vanishingly small amounts (0.010 - 0.015%) but like other agents such as chromium, nickel, vanadium, molybdenum, titanium, calcium, etc, it is rarely mentioned. Usually, a number of these are used together to make a steel alloy.

So that part of the advert is true. What I find hard to envisage is the claim about the scales/handle being made of aluminium and that it will not break, warp, the blade won't strike it, and it wont tarnish. I have several razors with such scales, and the statement in the advert about them is just not true in most respects.

Regards,

Neil

-

The Following User Says Thank You to Neil Miller For This Useful Post:

Geezer (02-16-2013)

-

02-15-2013, 01:57 PM #4

It's funny, I've got one of those F.S. Stanfield razors, but they misspelled "aluminum" on the tang stamp. Instead the stamp reads, "Alumium Steel"

-

02-15-2013, 02:03 PM #5

-

02-16-2013, 08:20 PM #6Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

In 1761 Guyton de Monveau called the base salt (alum) 'alumine'.

When Humphry Davy identified the metal in 1808 he first called it alumium and then changed his mind later and called it aluminum (1812). IN that year - following an objection of a reader of the Quarterly Review - the word was changed to aluminium.

Davy extracted it from the base - alumina. All the variants stem from the latin alumen, which simply means 'bitter salt'.

Aluminium was adopted as the official spelling in 1990, but soon after this was revised to include aluminum (1993). Aluminum is preferred by the USA and Canada, most of the rest of the world prefers aluminium. Strangely, aluminium was the preferred spelling in the USA until 1925. Even today though, chemists in the USA often use aluminium as it follws the convention of most elements ending in -ium.

Regards,

Neil

-

02-17-2013, 03:55 AM #7

Guess I need to brush up on my British English. What's that they say about the U.S. and the U.K. being to two countries separated by a common language?

Thanks. As always, interesting stuff.

-

02-16-2013, 12:15 AM #8

Back in the day aluminum was only used for scientific purposes. It could only be extracted from the mineral Cryolite which was then only found in Greenland and had to be hand mined part time. Aluminum was worth more than Gold. Mr Hall was sitting in a class and the instructor held up some aluminum and told the class if someone could come up with another way to extract and refine it they would be rich beyond avarice. He worked in a shed until he stumbled on the Hall Process which uses enormous amounts of electricity to do the job and now the "mineral" bauxite is the main ore now.

No matter how many men you kill you can't kill your successor-Emperor Nero

-

02-16-2013, 12:49 AM #9Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

-

02-16-2013, 01:26 PM #10Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote