Results 21 to 30 of 34

Thread: New razor: Dovo 88 (NOS)

-

05-17-2013, 12:20 PM #21Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

Yes, sure. Maybe I even go for the stones. I just wanted to see how good it is without doing anything to the blade.

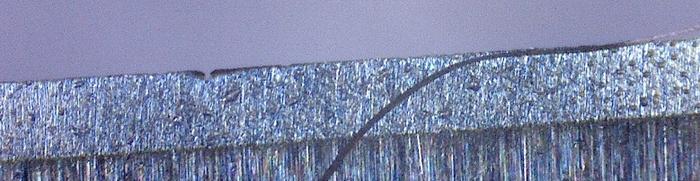

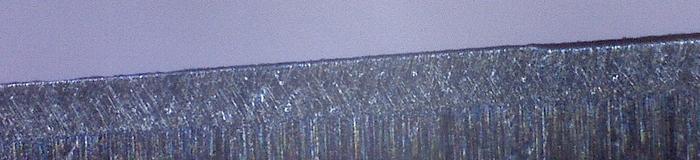

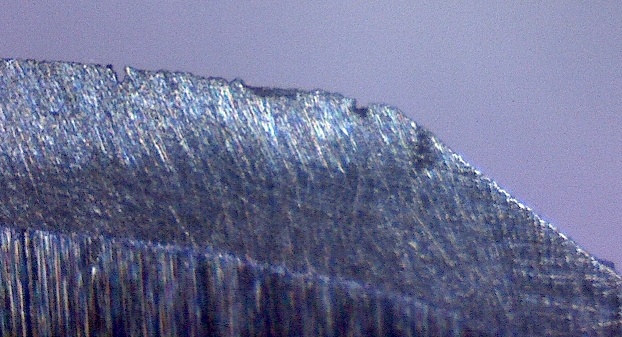

To give You an idea, this is what my DOVO 1516 - a current model - looked when I bought it:

the hair was there accidentally. It's very thin (cat?), but You see, it could easily catch in the slit and cause pulling.

No proper primary edge. The angle of the edge even changes halfways

tip

this one I would not call "truely shave ready".

-

05-17-2013, 12:53 PM #22Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,309

Thanked: 3228

Your experience with a NOS razor 75 years old when comparing the edge to a new production razor's factory edge is starting to confirm my suspicions that they paid more attention to the edge years ago at the factory than they do today. I wonder if it is lack of time or experience today?

BobLife is a terminal illness in the end

-

05-17-2013, 02:15 PM #23Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

I was suspecting that as well. That's why I wanted to try out the blade untouched, even without the cr-ox.

I assume it actually is the outcome of several factors.

First, I think, skills truely get lost. More and more things are done by machines or with a great support of machines. They do the job quick, reliable and precise. Only a few companies remain doing things by hand. Doing it by hand is more interesting but unhealthy, if not somewhat dangerous and more demanding. If in earlier days 1000 guys started their apprenticeship comming from school, each of them really had to do it. Today of 1000 it's probably only a handful that decide to go the dirty way. So once they're done, as a company, there is only a few to choose from for further employment.

Secondly, in all major "developed" countries wages have been rising tremendously and with only a few "experts" available, those have do be payed even better.

On the other side, we customers always call for best quality, but are not willing to pay the price for it. Instead we search the internet for the best bargin. So the small shop is not able to ask the price necessary and, in order to survive at all, needs to cut down its margin and cut costs where he can.

Additionally a change of thinking has taken place. In earlier times the owner tried to provide the best products and was proud of it. The company used to be handed over to the ancestors or best masters. Today there is a management in many companies. Guys comming from university with lots of ideas on how to maximize profit.

And last but not least, production technology has changed and knowledge about materials is a lot better. In earlier times you were not able to test products the way we can do it today. We do computer aided design and optimize to the max. As You were not able to that ancient times, You simply added something for safety - In Germany there used to be a rule of thumb that said "7 times safety". I guess that's why products up to the 1960s often still work while the water-kettle bought three years ago quits service shortly after the warranty has expired.

-

05-17-2013, 02:37 PM #24Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,309

Thanked: 3228

All good points on the demise of quality. Love the last one in particular, really no point in making a product that is too durable when you can force people to consume at a higher rate by making just adequate products. I am just happy that if you need/want the level of quality previously taken for granted that there is still NOS stock or individual craftsmen capable of supplying that level of quality.

BobLife is a terminal illness in the end

-

05-17-2013, 04:14 PM #25

Seriously nice find.

Mastering implies there is nothing more for you to learn of something... I prefer proficient enough to not totally screw it up.

-

05-18-2013, 01:16 PM #26Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

-

05-18-2013, 01:17 PM #27Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

-

05-18-2013, 02:39 PM #28Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,309

Thanked: 3228

Certainly true also but I'll take a higher durability margin if I can. I mean if you constantly run equipment at max plus as is common practice in the industry I worked in you are begging for trouble as most things are not "over engineered". Mind you that is from an operators point of view and not a bean counter's.

BobLife is a terminal illness in the end

-

05-18-2013, 04:24 PM #29Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

me too!

But we're the few that see certain things. The ones who prefer the 100year old blade over the mach3, even if it takes cuts and ages of red and irritated face. The ones who prefer to learn how to hone (and do that at night while others sleep in peace) - even if it takes a learning curve, a big amount of money and the risk of ruining the razor - over sending it out and let someone else do the job for 19.90 ...

-

06-04-2013, 11:06 AM #30Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote