Results 11 to 20 of 31

-

01-13-2017, 05:52 PM #11

I've learned to mute that out as I am thinking of other things during my shave. It took a while but I was able to get all of my Harts shaving at the top of the spectrum. Don't give up. The 01 tool steel loves stropping.

-

01-13-2017, 06:12 PM #12

I am a musician as well and prefer full hollow grinds, my romance with wedges was short lived. I enjoy the auditory and sensory feedback, and I subscribe to the theory that full hollows shave closer.

My instrument of choice is typically a 6/8 or higher Solingen with a finely executed hollow grind.

-

01-13-2017, 11:22 PM #13

My experience has been that while you can get a beautifully close shave with a wedge ground razor, they demand more attention to technique. As others have observed it's the lack of audible feedback that's mostly responsible, although there is also a lack of sensory feedback that plays into it as well.

-

01-23-2017, 12:21 AM #14Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,102

Thanked: 292

Update on my Hart 6/8" quarter ground.

I looked at my edge with a USB microscope and was concerned about the deep scratches in the grind that went all the way into the bevel. I decided to rehone the razor, initially without tape. I went all the way back to a 220 Naniwa superstone and set the bevel until it would shave hair on my arm. I then took it through my normal sequence of Naniwa 1K...12K. On the lower stones, I started with slurry and then diluted to water. Although sharp, the edge was still not great.

Finally, I added a layer of tape and took the razor to a Chinese 12K, starting with slurry and then finishing with water. This double bevel definitely made the edge more comfortable. I might even try it again with two layers of tape.

If I had paid the full price for the razor, I would have been quite upset. You should not have to hone a "shave ready" razor multiple times. Since I paid only $135 plus a $20 upgrade for Cocobolo scales, I decided to keep it. The experience of multiple honings, while not fun, did teach me more about how to handle the honing of problem razors. Although the Hart was a new razor, I had to treat it as if were a vintage restoration.

Currently, Classic Shaving is listing a sale price of $125 on Hart satin finish razors. Cost for anything other than black plastic scales will be extra. They are not showing any polished blade production Hart razors. Polishing the blade would have eliminated the issue I experienced with grind scratches. Even at the current sale price, however, I cannot recommend purchasing the satin finished razors.

Classic Shaving is still listing Hart Custom razors. Hopefully, the quality of workmanship that goes into these higher priced razors will be far better than mine. However, I won't be spending my money on one of them.

-

01-23-2017, 12:48 AM #15Senior Member

- Join Date

- Jul 2012

- Location

- Chicagoland - SW suburbs

- Posts

- 3,802

- Blog Entries

- 1

Thanked: 734

I have a Hart 7/8. I would have put it up for sale but I would not feel right taking someone's money for it. It's a lousy shaver and doesn't take good edge. But it looks nice. Once honed, it gives one good shave and the edge is gone. You can get as ha able edge on it but never a great edge. And it never lasts. I haven't used it in many, many months.

-

01-23-2017, 12:34 PM #16

-

03-10-2017, 10:14 PM #17Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,102

Thanked: 292

I wanted to post what I hope to be the final update on my Hart 6/8 quarter hollow that has been the subject of this thread. Yesterday, I received a new 5 MP USB microscope, so I decided to pull out the hones and try again on the Hart, checking every step along the way under the microscope.

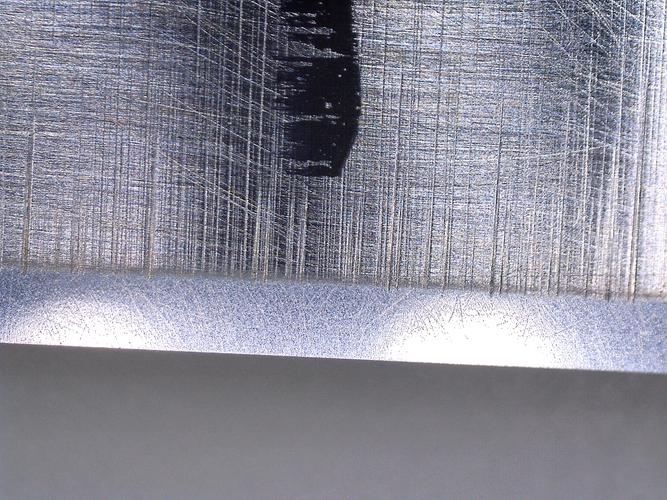

Previously, I had been able to get a respectable edge using a double bevel, but that was not keen enough for my liking. Thus, I decided to hone without tape. I completely killed the edge to remove any microchips and started by setting the bevel on a Naniwa 1K. I then proceeded through a series of Naniwas up through 10K with no microchips. Earlier, I had gotten some microchips on my 12K, so I decided to move from the 10K to natural stones. I used an ILR to remove the 10K scratches, but it left some scratches of its own. I finished on a C12K, leaving a hazy finish. There were no microchips. Here is a photo of the edge. You can also see in the photo some of the deeper scratches that extend through the face of the razor into the bevel.

I probably could have achieved an even better edge, but I did not want to take a chance on over-honing. I was afraid I might get microchips and have to start over.

The blade still does not shave as well as my full hollow blades, but it does meet my minimum standards for a shave ready edge. Since I purchased the razor at a steep discount, I never expected the razor to be in pristine condition. However, I did expect to be able to produce a shave ready edge. Although it took some effort to get there, I am satisfied with my decision to keep the razor. As long as it shaves satisfactorily, I can live with the scratches in the face of the blade.

-

03-11-2017, 12:49 AM #18Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I have hone a few Hart razors and they have all, been problematic. They are very hard and prone to chipping.

Removing a bit of the edge, seems to improve and hold an edge. They all were chippy.

I recall reading somewhere, that they were originally honed with a Micro Bevel for this reason. I suspect that because they are hard, most folks use more pressure with synthetic stones, causing more chipping.

I have had good luck honing Harts on lapping film, after setting a solid bevel on a 1k and removing 1k stria on a 2k, then move to film.

While you edge looks straight, there is a lot of random stria, that could be removed and leave a straighter, keener, smoother edge. Try some film and strop on CBN on a hanging strop.

A Jnat edge, that also might work well.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

RayClem (03-11-2017)

-

03-11-2017, 02:49 AM #19Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,102

Thanked: 292

Thanks Euclid440.

You mentioned that removing a little extra metal might reduce the chipping issue. Perhaps that is what I have done through my multiple attempts at honing with and without tape.

On synthetic stones, especially the hard 12K, excessive pressure will destroy the edge. Thus, I have learned to hone with the same light pressure I use when shaving.

I have not tried lapping film, but I do have a Tsushima ocean blue stone that has given me great edges on several other blades. I know it can give me a better edge than the one shown in the photo above. However, I need to be careful so I do not get back into chipping.

I know that a lot of American razor craftsmen (Hart, PRC, Nate's straights, Grim Blades and perhaps others) are using O1 tool steel and use a combination of heat tempering and cryogenic hardening and quarter hollow grinding. I know that those companies can all produce good razors, but with my unfortunate experience, I am hesitant to try another one. I know that Hart is trying to emphasize custom razors. I hope they have figured out how to eliminate the chipping issue.

-

03-11-2017, 04:14 AM #20At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,037

- Blog Entries

- 1

Thanked: 13249

The originals were chippy bastards because they were at 12-13 degrees so they needed 2 layers of tape

The ones after that first 6 months or so were good and have been until the last 6 months or so

We are now back to the chippy bastards and 2 layers of tape or a Micro bevel works (same angle)

Last week was Hart week up here I had 5 cross the hones 4 newer ones (chased chips) and one I had honed in the past (easy peasy)

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote