Results 1 to 10 of 31

Hybrid View

-

03-10-2017, 09:14 PM #1Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,091

Thanked: 292

I wanted to post what I hope to be the final update on my Hart 6/8 quarter hollow that has been the subject of this thread. Yesterday, I received a new 5 MP USB microscope, so I decided to pull out the hones and try again on the Hart, checking every step along the way under the microscope.

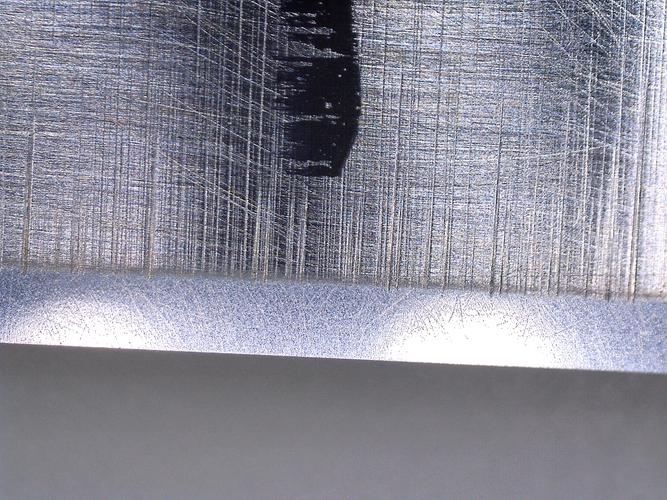

Previously, I had been able to get a respectable edge using a double bevel, but that was not keen enough for my liking. Thus, I decided to hone without tape. I completely killed the edge to remove any microchips and started by setting the bevel on a Naniwa 1K. I then proceeded through a series of Naniwas up through 10K with no microchips. Earlier, I had gotten some microchips on my 12K, so I decided to move from the 10K to natural stones. I used an ILR to remove the 10K scratches, but it left some scratches of its own. I finished on a C12K, leaving a hazy finish. There were no microchips. Here is a photo of the edge. You can also see in the photo some of the deeper scratches that extend through the face of the razor into the bevel.

I probably could have achieved an even better edge, but I did not want to take a chance on over-honing. I was afraid I might get microchips and have to start over.

The blade still does not shave as well as my full hollow blades, but it does meet my minimum standards for a shave ready edge. Since I purchased the razor at a steep discount, I never expected the razor to be in pristine condition. However, I did expect to be able to produce a shave ready edge. Although it took some effort to get there, I am satisfied with my decision to keep the razor. As long as it shaves satisfactorily, I can live with the scratches in the face of the blade.

-

03-10-2017, 11:49 PM #2Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I have hone a few Hart razors and they have all, been problematic. They are very hard and prone to chipping.

Removing a bit of the edge, seems to improve and hold an edge. They all were chippy.

I recall reading somewhere, that they were originally honed with a Micro Bevel for this reason. I suspect that because they are hard, most folks use more pressure with synthetic stones, causing more chipping.

I have had good luck honing Harts on lapping film, after setting a solid bevel on a 1k and removing 1k stria on a 2k, then move to film.

While you edge looks straight, there is a lot of random stria, that could be removed and leave a straighter, keener, smoother edge. Try some film and strop on CBN on a hanging strop.

A Jnat edge, that also might work well.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

RayClem (03-11-2017)

-

03-11-2017, 01:49 AM #3Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,091

Thanked: 292

Thanks Euclid440.

You mentioned that removing a little extra metal might reduce the chipping issue. Perhaps that is what I have done through my multiple attempts at honing with and without tape.

On synthetic stones, especially the hard 12K, excessive pressure will destroy the edge. Thus, I have learned to hone with the same light pressure I use when shaving.

I have not tried lapping film, but I do have a Tsushima ocean blue stone that has given me great edges on several other blades. I know it can give me a better edge than the one shown in the photo above. However, I need to be careful so I do not get back into chipping.

I know that a lot of American razor craftsmen (Hart, PRC, Nate's straights, Grim Blades and perhaps others) are using O1 tool steel and use a combination of heat tempering and cryogenic hardening and quarter hollow grinding. I know that those companies can all produce good razors, but with my unfortunate experience, I am hesitant to try another one. I know that Hart is trying to emphasize custom razors. I hope they have figured out how to eliminate the chipping issue.

-

03-11-2017, 03:14 AM #4At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,987

- Blog Entries

- 1

Thanked: 13234

The originals were chippy bastards because they were at 12-13 degrees so they needed 2 layers of tape

The ones after that first 6 months or so were good and have been until the last 6 months or so

We are now back to the chippy bastards and 2 layers of tape or a Micro bevel works (same angle)

Last week was Hart week up here I had 5 cross the hones 4 newer ones (chased chips) and one I had honed in the past (easy peasy)

-

03-12-2017, 06:34 PM #5Junior Member

- Join Date

- Oct 2015

- Posts

- 20

Thanked: 9

I love the feel of my new 6/8 hart but have to say it's not shave ready. No matter how I prep, lather or strop it never feels like it glides like my Dovo that was honed prior to shipping.

-

03-12-2017, 08:08 PM #6Senior Member

- Join Date

- Aug 2015

- Location

- Los Angeles

- Posts

- 287

Thanked: 72

I've been shaving with Hart razors exclusively for the last couple of years. I have two of the Custom Harts from Classic that were made by Bruce Gregory. They hold an edge for six months or longer with regular stropping and are a joy to shave with.

Although my Hart experience has been fantastic, I pay a lot of attention to other people's experiences with the company in the forums, on YouTube, etc. and from what I have seen, unless it is a higher end razor, you can pretty much count on it showing up not shave ready. I've seen this again and again and again.

So, if you see a great deal on a Hart, I'd pull the trigger, knowing that your gonna spend a little more money or time getting it dialed in. If you see a so-so deal, I'd probably pass. But big thumbs up from me on the Hart customs if you got the dough!D-rings, not handles

-

03-15-2017, 05:56 PM #7

Hello there, I have at least 10+ Harts I am at work so its a guess! I have had a speedy and painful learning experience in honing them. First off the steel is hard but does not like pressure WHAT!!!

So how do you set bevels and progress up the latter safely? I do not claim to have figured everything out here.

I use 1 layer of tape. When setting the bevel I don't use heavy pressure (light to a gentle medium at most) I let the stone do the cutting with one exception I refresh the surface of the 1k chosera once the surface smooths out, I do this until the bevel is set which could be a minimum of 3 times to more depending on the bevel size, but the bevel will be set without issue lurking as I move up the progression so I have found. It is worth it to set the bevel with light pressure on these harts!

After the bevel is set I move up the progression using enough (light) pressure to keep the blades edge torqued to the stone until scratches are removed on each stone (even the finishing stone), also during the progression I have found with certain stones cutting ability you may have to refresh the surface a couple of times. I have tried this process with synths and naturals with great success. I have even set the bevel the way mentioned above and went straight to a natural finisher until it was done and had great results too.

The strokes I use for each stone are circles, small back and forth strokes up and back down the stone and finishing X strokes to even out the sides. I don't count I go by feel, sight and physical results.

The key with harts "maybe" is using pressure is blaspheme LOL! The blades steel seems to enjoy finesse rather than force.

YMMV!!! Hope this helps, or at least it is worth a try

Last edited by dshaves; 03-15-2017 at 06:05 PM.

-

The Following User Says Thank You to dshaves For This Useful Post:

RayClem (03-15-2017)

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote