Results 1 to 10 of 41

Thread: Soft Steel Razors

Hybrid View

-

09-05-2020, 03:44 AM #1

When I hear 'soft steel' in regards to razors, I relate that to how easily it hones. A 1075 steel will hone easier than a 1095 steel at the same rockwell hardness due to less and smaller iron carbides. I suspect that these razors that we know as 'soft steel' are something close to 1075 with a hardness in the mid to high 50s.

-

09-05-2020, 02:34 PM #2Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

That is what I would suspect as well. I'm guessing that the coil spring I used was .55-.60 carbon (5160, 9260, 1060, etc...). It behaved as if it had even less carbon than old farm implement steel. While it certainly hardened and took a temper, the sparks were not near as abundant. Razors don't have to be very hard. If someone has a broken razor that was made in the 1700's or early 1800's, I'd love to have it for some testing. Even just the broken off toe would be enough. I could send it off along with a chunk of that coil spring for analysis.

-

09-05-2020, 04:48 PM #3

Coil springs are often 5160 which is .6% carbon, but importantly the added chromium lowers the eutectoid of that alloy to .6 %. In plain carbon steels the eutectoid is closer to .8 %. At the eutectoid, most of the carbon can be in the martensite leaving little to form, hard to abrade, carbides.

Last edited by bluesman7; 09-05-2020 at 04:53 PM.

-

09-05-2020, 07:15 PM #4

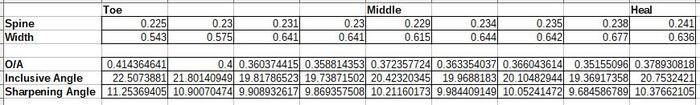

I once had a vintage razor that would not hold a 16° edge, but it would hold a 17° edge. Have you measured the bevel angle?

-

09-06-2020, 01:39 AM #5Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Interesting thought. It is so worn and uneven that it is a bit of a challenge to get a good measurement. Depending on where I measure, I get anywhere from 19.3 - 22.5. This to me indicates that it used to be considerably wider. It is honed with two layers of tape (as per the instructions that it came with). Now, I could re-hone it with no tape.

-

09-06-2020, 12:24 PM #6

Some people don't mind those obtuse angles, but I've never had a shave from a >19° edge that was better than meh.

Are you saying that those are the angles without tape, and then you're adding two layers?????Last edited by bluesman7; 09-06-2020 at 12:59 PM.

-

09-06-2020, 01:28 PM #7Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Those angles are with the tape. If I removed the tape, I my barely be within the "normal" range. You are correct about the shave quality. Meh is a good description.

-

09-19-2020, 11:45 PM #8Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Well the smoke has cleared out of the air. So I fired off the forge and turned a coil spring into a flat tapered piece of steel. Here it is after being pounded out and rough ground. There is still a ways to go yet.

-

09-22-2020, 06:33 AM #9Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

People can use ultrasound to figure out the composition of the steel without destroying it. I had someone tell me the type of steel under the chrome plating, so, I don't think polish should be a problem. If I remember one of my customers had someone drive 2 hours each way and test a few parts for less than $500. So it must not be that expensive if you take it in to them or even have someone local.

I not sure if they test hardness with an ultra sound, but there are nondestructive ways of getting that, too. Actually, you forge and heat treat, so you may have your own.

I have run into an issue before where the hardness test was inaccurate because the part was shot peaned. So the outside was harder than the inside. I know nothing of metal working practices in the olden days (or today, really) to know if anything done then could result in a similar issue.

So, I'm an engineer. If a customer wants me to analyze/reverse engineer a part I tell them to get it tested and they send me the results. So, I have exhausted my knowledge on the subject, but thought it may be worth looking into if you can't find a broken blade.Last edited by planeden; 09-22-2020 at 06:36 AM. Reason: Typo

-

09-22-2020, 02:36 PM #10Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

I know a place in Spokane with a hand held analyzer. I may be able to sweet talk them into testing it for me at no cost. One of the members on here had a broken blade at one point in time. He is looking around to see if he can find it. It would be really cool to get some actual data on one of these things and it would give me some targets to aim for.

67Likes

67Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote