Richard - I don't think that machine you gave the link for the patent for would make a groove like that - if you carefully read the description and the way in which the razor is presented to the wheels and the shape of the wheels themselves, it is simply another hollow grinding machine.

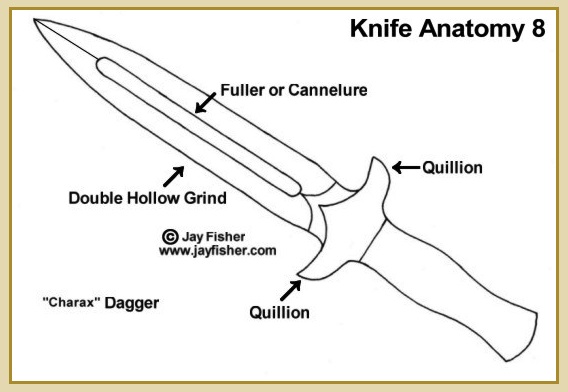

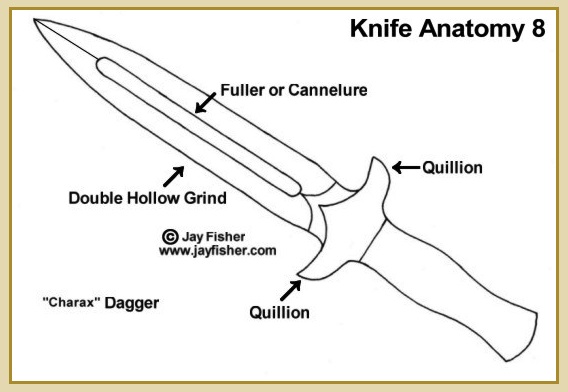

Re: it looking like a 'blood groove' - there is no such thing, as a simple google of 'fullering tool' and 'cannelure' will show.

The use of a blacksmiths fullering tool to spread the metal and form the groove might well have started the groove, but it would have been finished on a grinding machine. Indeed, in the days of hand-wrought blades it was common practice to impart the hollow by hammering the blade over a former or fuller, then for it to be finished on the wheel in the conventional manner.

Above: blacksmiths fullering tool.

I have seen many of these in older razors, and many were acid etched to hold a name or some-such. The end effect is similar to a rattler, but not quite the same.

As far as I know, fullering was usually practiced on knives and swords, not to allow blood to escape, but to lighten the implement without sacrificing any of its strength.

Above: fullering groove (or 'cannelure') on knife.

Regards,

Neil

106Likes

106Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote