Results 1 to 10 of 11

Thread: WB safety razor and NOS blade.

-

10-20-2015, 01:30 AM #1

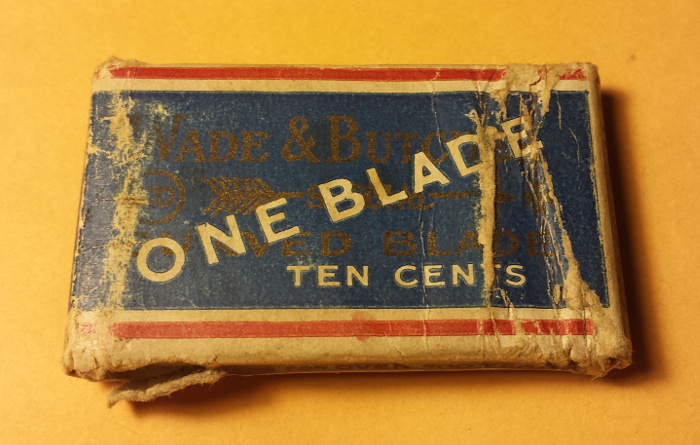

WB safety razor and NOS blade.

WB safety razor and NOS blade.

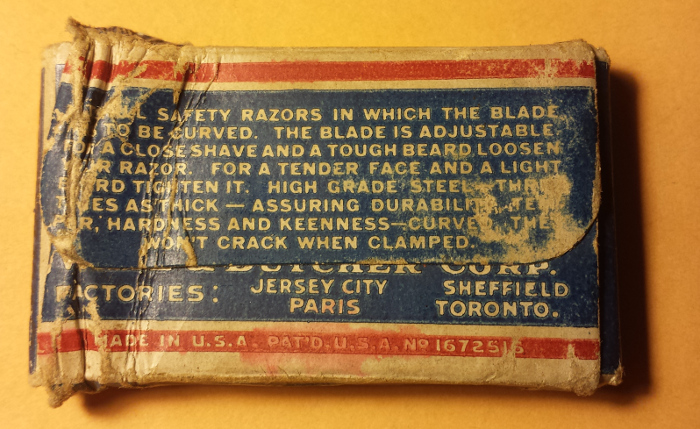

The blade wasn't sold as NOS but the packaging and sharpness of the blade suggest it is.

It feels shave ready to my thumb pad and whisks away hair on my arm with ease.

Tomorrow morning I'll test it out.Than ≠ Then

Shave like a BOSS

-

-

10-20-2015, 01:56 AM #2

Let us know, cause I have one too with some blades, I have yet to try.

-

10-20-2015, 02:26 AM #3

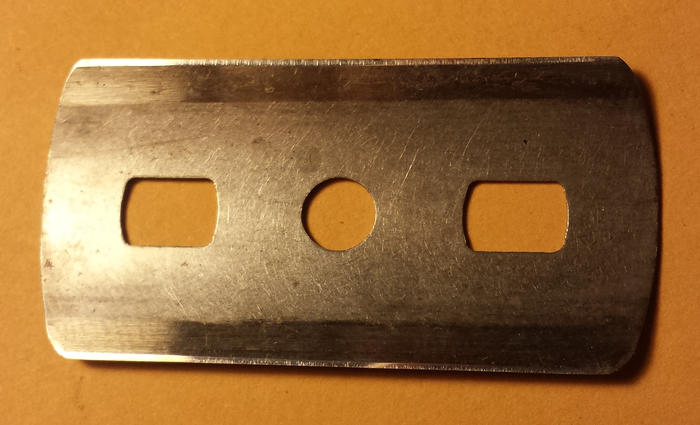

I have one as well. Jimmyhad told me it would work with modded DE blades, I have yet to try. The two pins have the square bases canted on the Butchers. A bit of discretionary scissor-clipping seems necessary.

Hey! I made a Segal work that way! "Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

10-20-2015, 11:25 AM #4

-

10-20-2015, 02:22 PM #5

I think a pair of sturdy scissors, modding the blade while holding it inside an open cardboard box to catch the trimmings.

I will try it!

Like I said, it worked on my Segal! "Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

10-25-2015, 03:00 AM #6

The blade was not up to the task, unfortunately. It cut but tugged a lot, reminding me of the NOS Henckels safety blades I got with the razor. Given enough time, they just get dull. Probably corrosion even though they looked like new.

An alternative would be to round the square posts. I do have two now, one in extremely poor condition that might lend its self to experiment.Last edited by Hart; 10-25-2015 at 03:03 AM.

Than ≠ Then

Shave like a BOSS

-

10-25-2015, 06:12 AM #7The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,737

Thanked: 481

I offered at one point way back when to attempt to sharpen an original blade.

Hart, If you would like, I repeat my offer to you. I'm willing to give it a go if you are! =)

-

10-25-2015, 02:00 PM #8

As the blade is useless as is, and there being nobody with successful experience to share, something could be done

. What ideas do you have for sharpening one? I hone my own razors with some success, but I don't have much experience.

Than ≠ Then

. What ideas do you have for sharpening one? I hone my own razors with some success, but I don't have much experience.

Than ≠ Then

Shave like a BOSS

-

10-25-2015, 02:31 PM #9

At least ignorance is comedy, if not bliss.

At least ignorance is comedy, if not bliss.

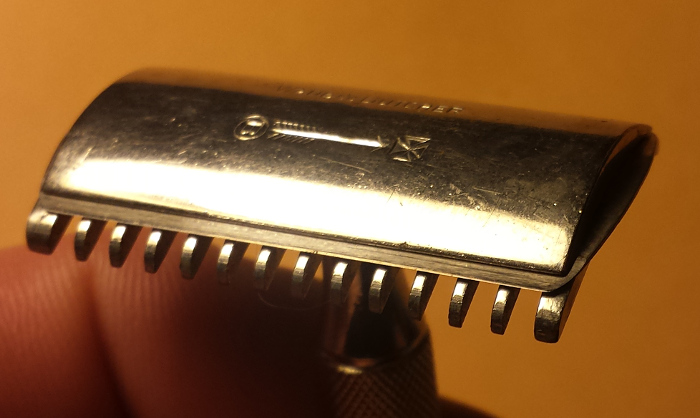

OK, here are the pieces I had got together for the two wb safety razors.

1. Open comb from another old razor.

2. WB blade.

3. Good WB top cap.

4. Rough WB top cap.

5. Good WB bottom plate.

6. WB handle.

7. What came with rough WB cap.

I don't know where #7 came from but I got it with the rough cap, that did not come with the bottom plate.

You can see here the rust from the WB blade on #3, the blade is not stainless steel.

If you use one you definitely have to take it apart after each shave and dry and oil it.

Also, #4 has already been modified for regular blades, something I didn't even notice at first.

Here are #4,5,6 assembled with a Wilkinson blade. Note the bend in the cap.

I took a chance and tried it out. It shaved well and was still less aggressive with its bend than my R41

Once straightened I think it will be a nice shaver.Than ≠ Then

Shave like a BOSS

-

10-27-2015, 02:40 AM #10The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,737

Thanked: 481

I don't really know how I would hone a W&B safety razor, as I have never held one in my hands. My tactile brain needs to feel what kind of flex it has, and my eyes need to study the angles and what sort of fixture or jig I come up with will depend on the random facts I do not yet posses!

28Likes

28Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote