Results 11 to 20 of 21

Thread: Yard sale jackpot

-

08-20-2020, 01:17 AM #11Member

- Join Date

- May 2010

- Location

- New York

- Posts

- 94

Thanked: 9

Weird.

See, THESE are the kind of oddball little curiosities that i would abuse time travel for. Forget the big, important stuff lol

-

08-20-2020, 05:51 AM #12Member

- Join Date

- May 2010

- Location

- New York

- Posts

- 94

Thanked: 9

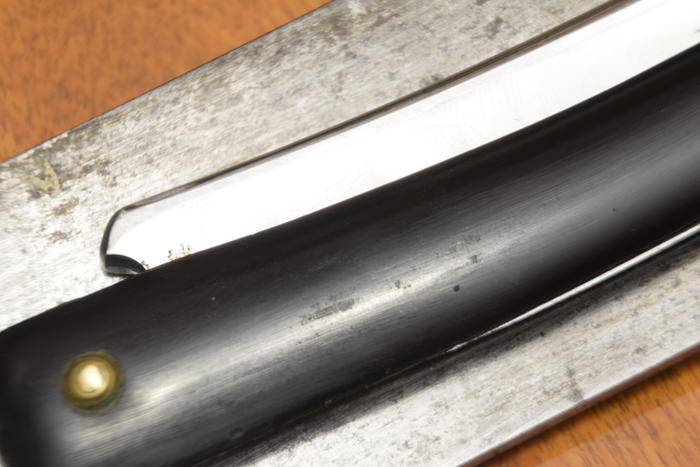

Here's the pics of the damaged scale on the WB Barber's

There's some general chipping around the edges, nothing that can't be sanded down and re-shaped

This is the only big chip, so that end would have to be a little more rounded once done

You can also see here where someone filed down the pivot pins

This is the bad spot by the wedge, where the razor got crushed down into them.

4 cracks around the wedge pin, the worst of it is bent out to the side and missing a small chip

Squeezed down so tight you can see the blade from poking through the back

If i had to guess, i would think something like this, let me know if I'm on the right track?

Unpin carefully, save the washers.

Steam the scales to soften the horn

Sandwich them around a flat piece of wood, then clamp them with some leather between the scales and the vise and let them cool. Repeat if necessary.

Thin CA to stabilize the cracks?

Grab another piece of horn and some fine sandpaper and make some powder, make a paste with a dab of epoxy and the horn dust, and patch the missing bit (would have to test this first, works with sawdust, not sure about horn dust. Maybe just black dyed epoxy, and first depending on how bad the chip even is once everything is squeezed back together)

Then soak them in neatsfoot oil for a while.

Wet sand with the oil

Then decide on a satin finish or buffing.

Reassemble with the original washers and wedge and fresh brass pins (after practicing repinning on a bunch of less awesome things first! Not very experienced with that, and not going to rush this)

Oh, and clean up the blade while it's out of the scales, of course.

Lemme know if I've overlooked anything, or if I'm off base on any of those thoughts?

Particularly if thin CA is best for stabilizing cracks in horn? Never tried glueing this stuff before

-

08-21-2020, 02:13 AM #13

I would use dust from something like ebony or bog oak to mix with the epoxy or CA to fill the voids. My experience with horn dust is that it's not very black.

-

The Following User Says Thank You to tintin For This Useful Post:

Kavik79 (08-21-2020)

-

08-21-2020, 02:20 AM #14Member

- Join Date

- May 2010

- Location

- New York

- Posts

- 94

Thanked: 9

Yeah, i was second guessing that as i was writing it, that's why I said I'd have to test it first

It's been a few years since I've sanded horn

-

08-21-2020, 10:32 AM #15

You can also burn a few wooden matches, remove the heads, and grind up the charred sticks. Makes a perfect filler for CA or Epoxy.

Mike

-

The Following 3 Users Say Thank You to outback For This Useful Post:

Kavik79 (08-21-2020), randydance062449 (08-21-2020), tintin (08-21-2020)

-

08-21-2020, 02:14 PM #16Member

- Join Date

- May 2010

- Location

- New York

- Posts

- 94

Thanked: 9

Interesting. I'll have to give that a try too, and see how they compare.

I also have some powdered pigments on hand here that i could try, if the other options don't get it dark enough

-

08-21-2020, 02:52 PM #17

-

The Following User Says Thank You to outback For This Useful Post:

Kavik79 (08-21-2020)

-

08-21-2020, 03:15 PM #18Member

- Join Date

- May 2010

- Location

- New York

- Posts

- 94

Thanked: 9

-

08-21-2020, 05:58 PM #19

-

08-24-2020, 02:49 PM #20Senior Member

- Join Date

- Sep 2017

- Location

- Upstate New York

- Posts

- 641

Thanked: 104

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote