Results 11 to 18 of 18

Thread: New 7 Day Set Case

-

03-30-2012, 10:16 PM #11Senior Member

- Join Date

- Aug 2011

- Location

- Toronto, Canada

- Posts

- 233

Thanked: 22

Cut 6 pieces of 1/4 inch thick MDF about 1/2 inch wide to the inside width of your box. Measure exactly, and if you err, make sure the pieces are too long rather than too short.

Line the inside of your case with a velvet or similar fabric. The 6 dividers you cut will now be just a touch too big to fit across your case.

Very gently sand or file the end of the divider till it fits snugly with a friction fit. Take your time on this, if you take off too much material you'll have to scrap that piece and make another.

Now glue the same fabric you used for the lining on one side of each divider. Use a piece of fabric that is about 1/2 inch longer and about 3-4 times the width of the divider. Leave about 1/2 a divider width overhanging. Let the glue dry completely. Use a weight along the length of the divider to make sure the fabric adheres everywhere.

Spread glue on the top and other side of the divider and fold the fabric over them. This is where it gets a little tricky. You have to make sure the fabric is tight along the entire length of the top of the divider. You should now have an overhang of fabric again. Put some weight on the divider and let the glue dry completely. Don't be tempted to check on it or remove the weight.

once the glue is dry, trim the edges flush with a razor blade. You will have one of the 1/4 inch faces exposed, but that will be the bottom anyway.

You now have a set of dividers that fit snugly, look as though they are a part of the case, but are still re positionable.

Its not a quick process, but trust me, after a ton of experimentation, its the best way i've found for fabric lined cases.

Joe

-

03-31-2012, 10:27 PM #12Senior Member

- Join Date

- Jan 2012

- Location

- St. John's, Newfoundland and Labrador, Canada

- Posts

- 164

Thanked: 11

That's a good way to do it, been thinking along those lines. My case is a bit different though then yours. For one, it's not for a 7 day set, I only have 3 razors so far (4th is in the mail) and they're all different, I just wanted a semi-nice case to keep them in. So I need mine to hold razors that may be slightly different in size. I have some foam I was thinking of using for this, just haven't decided if I should wrap it around wood or just use the foam, it is pretty stiff. The other thing is I didn't build the box, it's a cheap plywood box I got for $2 at the local dollar store that I sanded and stained and lined the insides with red velvet. It's a bit deeper then I need so I made a false bottom, just enough room to hide money or something thin in. So I need a way to pull the whole thing out to access the hidden space and I'm worried if I do spacers the width of the box there will be too much friction. Been doing some experimenting with scraps and a couple of other boxes of different sizes I got at the same place for the same price.

I don't want to steal your thunder here in this thread though so maybe I'll start my own for my box. Once again, great work on yours, I'll be making a nice box from scratch one of these days, just not yet.

-

03-31-2012, 10:29 PM #13Senior Member

- Join Date

- Jan 2012

- Location

- St. John's, Newfoundland and Labrador, Canada

- Posts

- 164

Thanked: 11

Forgot to ask, how did you line the sides? Curious if you did like I did. I figured cutting and gluing velvet to the wood would be a pain so I glued it to cardboard with the edges folded over the back and then glued the cardboard to the sides and bottom of the box.

-

04-01-2012, 12:05 AM #14Senior Member

- Join Date

- Aug 2011

- Location

- Toronto, Canada

- Posts

- 233

Thanked: 22

Don't worry about hijacking the thread...We're supposed to share

I line my cases directly to the wood. Here's a brief explanation. You can look at the picture to kinda get what I mean.

The first thing to do is measure the width of your case and cut a piece of fabric that is the same width. The length needs to be more than the total of the front, bottom, back of the bottom PLUS the back, top and front of the top portions.

I glue the fabric to front, bottom and back portions of the bottom half of the case, leaving an overhang on the front.

Once that has dried I open the case to 90 degrees, brace it in that position and glue the rest, making sure the fabric is taught across the hinged back. This does two things.

1. it hides the hinges when the case is open

2. It acts as a stop so the case does not flop open

Again, once the glue has dried, trim the overhangs with a razor blade.

Now you have to line the sides.

Do that one at a time, taking care to cut the fabric to exactly the length needed so that you don't have an overlap on the existing lining. Trim the overhang with a razor blade.

Its a slow process and if you're not the patient type, it can be very frustrating.

If you're going to attempt a scratch built case, be prepared for a learning curve. There are a bout 48 different opportunities for mistakes in the process, any one of which can be fatal to the project. Don't ask me how I know

-

04-01-2012, 10:25 PM #15Senior Member

- Join Date

- Jan 2012

- Location

- St. John's, Newfoundland and Labrador, Canada

- Posts

- 164

Thanked: 11

That's really cool with the fabric covering the hinge. It's too late for me to do something like that but this box is more about learning for me anyway, I'm sure I'll do another.

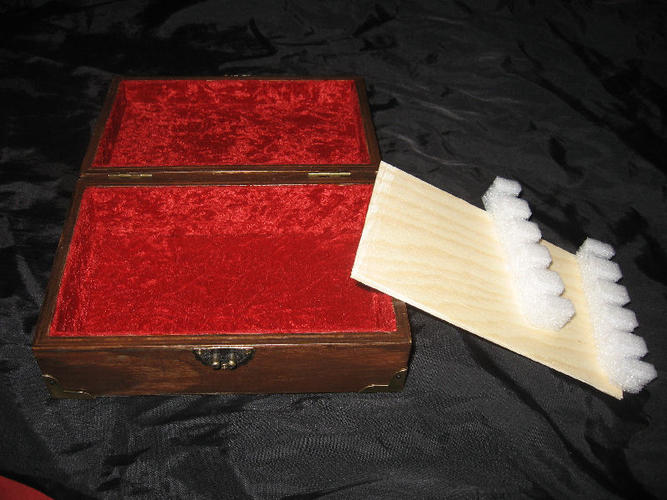

Here's what I have so far. The piece of wood will be the bottom and the foam pieces were one idea I was messing with but I don't think I will use. I do want a design where the foam "grips" the scales, holding the razors firmly and able to adjust for different sizes. I like this foam, it's stiff and doesn't melt when contact cement is applied.

-

04-01-2012, 10:49 PM #16Senior Member

- Join Date

- Aug 2011

- Location

- Toronto, Canada

- Posts

- 233

Thanked: 22

The case looks nice...you just have to figure out what you're doing with dividers.

I considered the foam idea, but I wanted the inside my cases to look really uniform and I never really transport, lean or invert the cases so I don't have to worry about gripping the razors tightly. Also, I"m pretty good about making sure my razors are clean and dry before they get put away, so the fabric is not an issue.

Keep working on it, the perfect solution for you is out there somewhere. The journey is half the fun

By the way, its probably not too late to do the fabric hinge thing on your case, but it does get a lot trickier with making sure you cut the new piece to EXACTLY the right size. Once its glued in place, if it overlaps the bottom or top there's no turning back.Last edited by joebehar; 04-01-2012 at 10:53 PM.

-

04-03-2012, 11:37 PM #17

-

04-04-2012, 01:04 AM #18

Beautiful...

Well done !

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote