Results 11 to 16 of 16

-

02-26-2020, 11:20 PM #11Senior Member

- Join Date

- Sep 2009

- Location

- Plymouth, UK

- Posts

- 313

Thanked: 19

I see, I more or less get the picture. I have not heard of 'ferric oxide pigment' before.

I also get the point about a smaller more structured strop. I have a Herold loom strop with one side charged with green paste (CrOx?). This works really well, I usually use it after getting the edge as far as I can with my stones, before moving to plain fabric and leather strops. 20-30 very light laps make a huge difference.

I have an old paddle strop on which the leather is perished, I have been thinking of replacing the leather with a piece of balsa. That might also be an experiment worth trying with the pastes.

Many thanks!

-

02-27-2020, 12:10 AM #12Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Fabric makes a great pasted strop as the paste imbeds in the weave and will last years. Cotton, nylon and polyester make great pasted strops.

If you want to experiment and wish to make excellent dirt-cheap strops, make them from Pellon, a brand name fabric/paper, similar to Tyvek but not as slick. It is available at any fabric store or in USA any Wal-Mart for under $3 for a 36X45 inch piece. A yard length will make 15-20 strops depending on width. I have made hundreds of these strops.

It can be folded on itself and D rings attached with fabric iron on fusing tape. This bond is stronger than the fabric. I have in the past posted the process of attaching the D rings with photos.

I have even made strops from brown paper shopping bags that can easily be pasted and last surprisingly well. Just fold and glue over a D- ring.

Here is one post demonstrating this technique with a Polyester Canvas/Sailcloth strop and 2” D-ring.

CBN Strop

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Montgomery (02-27-2020)

-

03-02-2020, 02:34 PM #13Senior Member

- Join Date

- Sep 2009

- Location

- Plymouth, UK

- Posts

- 313

Thanked: 19

Many thanks!

A general question: I have seen in various sources that the cutting particles in a 4000 grit stone are 4-5 microns (eg https://en.wikipedia.org/wiki/Sharpening_stone). I have also seen chromium oxide powder and red ferric oxide powder advertised with particle sizes of 0.5 and 0.3 micron respectively (eg https://www.ebay.co.uk/itm/264631273241).

I know there is much more to abrasive quality that the size of the cutting particle, but how do I square these numbers with the particle size in the list above for the Herold pastes?

-

03-02-2020, 05:48 PM #14Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So, there is grit (partial) size and there is finish quality. A lot depends on the grit, is it friable, (will it break down further), how deep will it cut, (partial shape) and the substrate, (does the grit imbed into the substrate, leather vs wood). All affect the ability to “Polish”.

Take Arks and Jnats, some say all Ark grit and Jnat grit respectively are the same and the difference is in the concentration and binder.

Bottom line, it is not just about grit size. Add to all that steel, substrate hanging vs paddle and technique, are why paste works for some and not for others, your mileage may vary.

Here are photos from an old post on the effects of pressure, (just one variable)

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Montgomery (03-03-2020)

-

03-02-2020, 06:07 PM #15

I use those postes on my SRD modular paddle strop and am very happy with the results

-

The Following User Says Thank You to AlanQ For This Useful Post:

Montgomery (03-03-2020)

-

03-03-2020, 12:30 PM #16Senior Member

- Join Date

- Sep 2009

- Location

- Plymouth, UK

- Posts

- 313

Thanked: 19

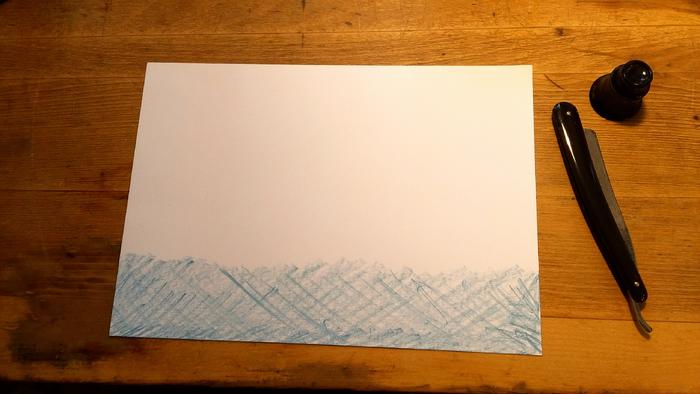

After the advice, I got some of the Herold hard strop pastes, and pasted up one of the cotton webbing strops:

First impressions are that the black paste is where it's at. The red seems a bit like the green (pre-loaded on my Herold loom strop) in quality, just finer. The black seems to be really smooth, and though I need a few more laps, it really seems to add keenness to the edge. Anyway, I will experiment, and get to know these compounds.

For anyone wanting to experiment with stropping, I have definitely found this suggestion very useful. You can put anything on a piece of card and try it. I just tried tailor's chalk:

(for anyone interested, the tailor's chalk left very fine scratches in the bevel, which polished out quickly with stropping on plain fabric; it could definitely be used for stropping, and I'd suggest it could be used to refresh a slightly dulled edge. I'm not going to use it regularly, because it doesn't really add anything new to the toolkit)

Many thanks!

-

The Following User Says Thank You to Montgomery For This Useful Post:

JP5 (03-05-2020)

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote