Results 1 to 10 of 32

-

10-21-2005, 10:55 PM #1Member

- Join Date

- Sep 2005

- Posts

- 37

Thanked: 0 Hand American 6.0 micron compound.

Hand American 6.0 micron compound.

I ordered a flatbed hone from Hand American, to make up for a delay in shipping they included their 1.8 and 6.0 compounds for free.

Now I'm wondering what to do with it.

Now I'm wondering what to do with it.  I have a textured leather hone so I figured I'd use that with the 6.0micron stuff but I'm wondering if I should.

I have a textured leather hone so I figured I'd use that with the 6.0micron stuff but I'm wondering if I should.

What's the worst that could happen if I started on the leather hone then moved to the 8K side of the Norton?

-

10-22-2005, 01:03 AM #2Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

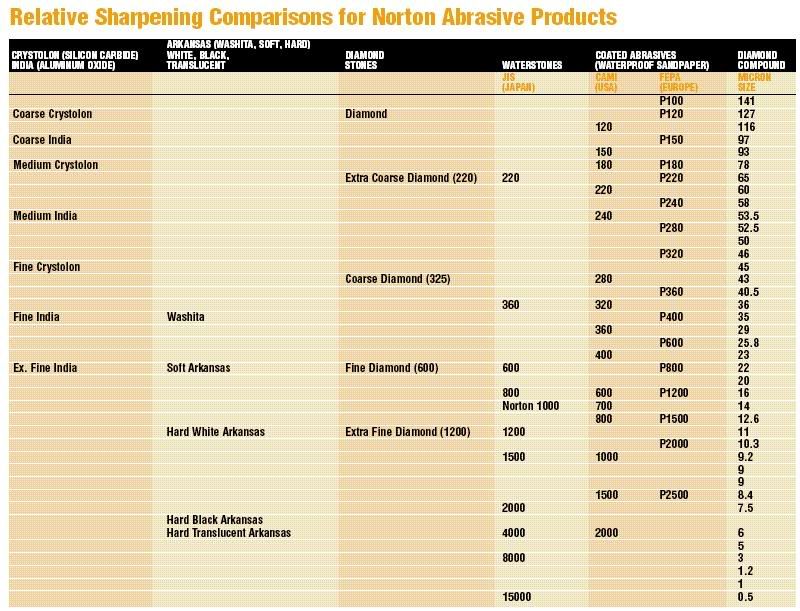

I just looked in the Help file section on Honing and the Norton JIS/FEPA/Micron chart.

6 micron is approx 4000 JIS

1.8 "" 6000 JIS

1.0 " 8000 JIS

The progression would be logical but others who have used this on leather for honing would be the ones to ask.

I go from hard stones to soft pasted leather.

I have never used a pasted leather for all my honing.Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

10-22-2005, 06:12 AM #3

There's quite a bit of confusion on these equivalents. If you look at the diamond paste data, a 6 is 3K, a 3 is 8K, a 1 is about 14K and a .5 is 50K.

There's quite a bit of confusion on these equivalents. If you look at the diamond paste data, a 6 is 3K, a 3 is 8K, a 1 is about 14K and a .5 is 50K. Originally Posted by randydance062449

Originally Posted by randydance062449

-

10-22-2005, 04:13 PM #4

There are a number of international "standards" and the numbers don't align (ie, 4000 in one isn't 4000 in another). And, you have the problem of what does 4000 mean? Is it the mean, average, or max size of the particles that make up the abrasive... different manufacturers use different methods to spec their products.

There are a number of international "standards" and the numbers don't align (ie, 4000 in one isn't 4000 in another). And, you have the problem of what does 4000 mean? Is it the mean, average, or max size of the particles that make up the abrasive... different manufacturers use different methods to spec their products. Originally Posted by Joe Lerch

Originally Posted by Joe Lerch

I like the chart I've included below (copied from a Norton brouchure), but there's disagreement as to it's accuracy because there are other charts with conflicting information. Geez... you'd think a micron is a micron in any situation, lol.

-

10-22-2005, 04:34 PM #5

Joe, Randy,

Even more confusing between the two charts is that Norton and Amplex are the same people....all part of St. Gobain.

Somehow the abrasives being in suspension vs. boned into a stone must have some bearing on this. I know the Amplex compounds are actually a mixture of different sizes so the micron rating is really an average of the sizes.

On hard stones some feel more coarse than others despite the grit rating. Many like the Norton 4K are fast cutting which means the oarticles are spaced to allow for free cutting. The grit s fine, the spacing is far making it feel a little rougher than a Japanese stone which tends to be very slow cutting.

TonyThe Heirloom Razor Strop Company / The Well Shaved Gentleman

https://heirloomrazorstrop.com/

-

10-22-2005, 05:58 PM #6Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I agree with all of the above comments!

The best starting point is the micron size. After that you pay attention to the actual results on your blade.

I just acquired a 8000 Kitayama Japanese waterstone and tried it yesterday for the first time.

It was so slow!!!!!

I will try some more razors on it in the future to give it a fair test. Maybe its best use is as a touch up hone? Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

10-22-2005, 06:24 PM #7

I agree, Randy... there's really little else we can do.

I agree, Randy... there's really little else we can do. Originally Posted by randydance062449

Originally Posted by randydance062449

Regarding differing standards of measurement, here's a good overview from the Wood Artistry website... as you can see, there's little hope of using just "the numbers" to compare products from different manufacturers, different countries, and (as Tony pointed out) constructed using different process technologies.Why are there such differences in the numbers and words used to identify abrasive grit sizes? The numbering systems used to identify abrasive grits are designed to meet standards of different countries or are measured with different methods.

- Mesh Grades : The most common methods used in the USA are mesh grades, which are screens of mesh that abrasives can fall through. The finer the mesh, the smaller the grit size, so a 120 mesh is coarser than a 180 mesh.

- Micron sizing : With this system, the grit is measured in microns (one millionth of a meter), and a 120μ (micron) grit is finer than an 180μ grit.

- CAMI: The USA measurements are defined by “ CAMI ” ( Coated Abrasives Manufacturers' Institute).

- FEPA: European abrasives are defined by “FEPA” (Federation of European Producers of Abrasives). With this system, a P with the grit size indicates a coated abrasive while an F indicates a bonded abrasive.

- JIS: The Japanese system for measuring abrasives is defined by a “JIS” (Japanese Industrial Standard) document.

Note: Cross references are made by several sources, but do not always agree, as there is not an exact equivalent of all abrasive grades. One listing of an 8000 grit water stone equates it to 3μ while another says it is 1.2μ. CAMI 360 mesh grit is listed as being 28.80μ, while a FEPA P360 and JIS 360 are listed at 40.50μ. The numbers do not always equate to other measurement systems

-

10-22-2005, 08:18 PM #8

I understand what you mean about the different standards for grit. What I don't understand is if you pick a standard, pastes with the same micron size sometimes come out to be different grits under the same standard.

I understand what you mean about the different standards for grit. What I don't understand is if you pick a standard, pastes with the same micron size sometimes come out to be different grits under the same standard. Originally Posted by azjoe

Originally Posted by azjoe

-

10-22-2005, 09:13 PM #9

This stone is sometimes marketed as a 12k Randy. I have been told that the effective grit is somewhere in the 12-15k range once a slurry is raised. Could that be why it seems slow to you? Of course nothing that I have tried cuts faster than Shapton pro stones..

This stone is sometimes marketed as a 12k Randy. I have been told that the effective grit is somewhere in the 12-15k range once a slurry is raised. Could that be why it seems slow to you? Of course nothing that I have tried cuts faster than Shapton pro stones.. Originally Posted by randydance062449

Originally Posted by randydance062449

-

10-22-2005, 09:31 PM #10

When you feel the dry surface does it feel coarser than a 12K?

When you feel the dry surface does it feel coarser than a 12K? Originally Posted by Korndog

Originally Posted by Korndog

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote