Results 21 to 30 of 42

Thread: X-stroke or not?

Threaded View

-

05-15-2013, 06:11 PM #1Senior Member

- Join Date

- Sep 2011

- Posts

- 224

Thanked: 20 X-stroke or not?

X-stroke or not?

Earlier, I hi-jacked a thread titled "Which strop should I buy?" when I asked Glen (gssixgun) to elaborate on a statement about using an x-stroke versus a straight stroke - basically why would an x-stroke improve an edge and give a better shave over a straight stroke when stroping on a 3" strop. I want to elaborate on the question a little and throw in what I think is part of the answer. For this discussion please assume proper technique.

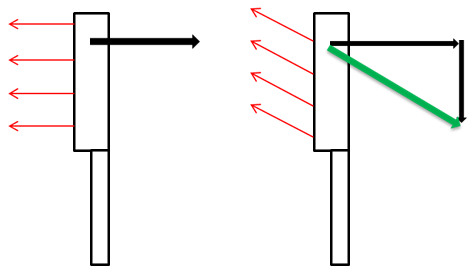

When using a straight stroke, there is only one vector that describes the movement of the razor across the strop; one that is parallel to the strop. This is represented by the black arrow in the first diagram. In this case, the stroping action will have its effect on the edge in a manner shown by the red arrows - essentially by exerting some force on the edge that is in a direction that is opposite to the vector of the razor's movement.

When using the x-stroke, the vector that describes the movement of the razor is the addition of two vectors - the movement of the razor along the length of the strop (the horizontal black arrow in the second diagram) and the pulling of the razor toward you, perpendicular to the strop, to execute the "x" of the x-stroke (the vertical black arrow in the second diagram). The actual movement of the razor is shown as the addition of these two vectors; the green arrow in the second diagram. Therefore, the force exerted on the edge in this case is such as shown by the red arrows, again in a direction opposite to the vector of the razor's movement.

If the x-stroke (even on a 3" strop) actually improves a shave by improving the edge over that obtained by a straight stroke, I contend that the reason must lie somewhere within this phenomenon (where or how exactly I don't know). A point was brought up about full contact of the edge with the leather; I do not buy this - unless the "imperfection" in the strop (hills, valleys, bumps) runs perfectly parallel to the stroping stroke along the entire length of the strop, I am willing to bet that the entire edge will contact the leather at some point during the stroke.

I do not contend this to be an answer, but I am willing to bet that the answer (if there is one) lie somewhere in this domain. Even in a hobby where YMMV is the norm, we are still operating in the physical world, and this is the physics as I see it. Please point out if and where my reasoning is flawed, and point out my mistakes in logic.

As always, thanks for any and all replies -GagsLast edited by Joegags; 05-15-2013 at 06:42 PM. Reason: fixed a spelling error

27Likes

27Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote