Results 1 to 10 of 36

Hybrid View

-

10-11-2013, 02:39 PM #1

How to efficiently cut slabs for scales?

How to efficiently cut slabs for scales?

This is one I've been trying to work out for a while without buying yet another piece of machinery. I'll buy more equipment if it'll solve this, but before I do I thought I'd run it by the forum since most of you have probably already solved the issue.

I have a few boxes of exotic hardwood pieces that are all in various shapes - from 3/4" thick up to 8" and larger - as well as some thick pieces of other materials. I'll sometimes just use my compound saw to cut a few slabs for scales but the kerf of those blades are almost as thick as what the final scale will be - and that just seems like a terrible waste of wood. Tried using the scroll saw but that gets uneven slabs since I can't figure out how to make a good ripping guide for it. That results in almost as much waste as a result of sanding to get the slabs flat. Hand sawing using a very thin blade works, but again, uneven slabs.

So, does anyone have an approach that results in 1/8 to 3/16 thick wood slabs that doesn't involve a kerf that's just as thick? Couldn't find a thread on this at first look but there may be one in here that I can't see. Seems like a little table saw that uses a really thin blade would work but I can't find one online and Woodcraft doesn't seem to have what I need.

On a side note, I've had RAD and HAD for years, but this may simply be a symptom of some "restoration equipment acquisition syndrome" as well as signs of "scales material acquisition syndrome" as well.

Mike

-

10-11-2013, 03:07 PM #2Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

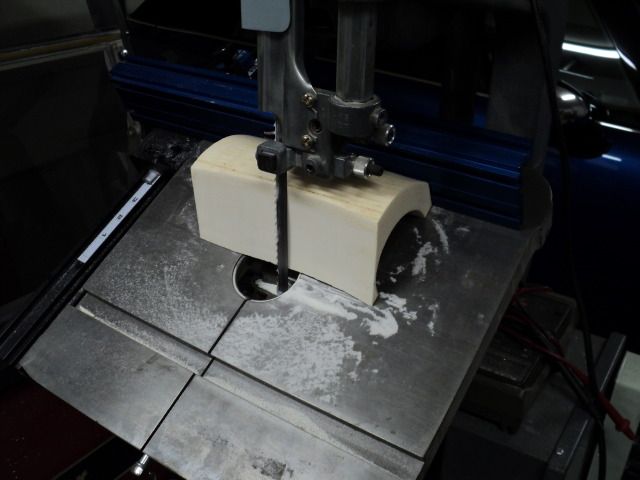

I use a band saw with a rip blade. Ripping thin stock with a compound miter saw is an accident waiting to happen - can't recommend that to anyone. Not a good idea on a table saw either. If you are serious about this, get a band saw. Used ones are available at reasonable prices. Good luck. I share your TAD.

-

The Following User Says Thank You to skipnord For This Useful Post:

AirColorado (10-12-2013)

-

10-11-2013, 03:09 PM #3

You can buy thin kerf blades that will greatly reduce your waste.

One time, in band camp, I shaved with a Gold Dollar razor.

-

The Following User Says Thank You to eod7 For This Useful Post:

AirColorado (10-12-2013)

-

10-11-2013, 03:19 PM #4Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Last edited by pixelfixed; 10-11-2013 at 03:27 PM.

-

The Following User Says Thank You to pixelfixed For This Useful Post:

AirColorado (10-12-2013)

-

10-11-2013, 03:41 PM #5Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

My fence is a piece of 1x2 and 2 C clamps.

-

The Following User Says Thank You to skipnord For This Useful Post:

AirColorado (10-12-2013)

-

10-11-2013, 03:48 PM #6Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

10-11-2013, 03:42 PM #7

-

The Following 3 Users Say Thank You to Geezer For This Useful Post:

AirColorado (10-12-2013), skipnord (10-11-2013), spazola (10-26-2013)

-

10-26-2013, 12:48 AM #8

Exactly what I do. I might think the same technique could work for a scroll saw, but it would certainly be using the saw in a way it wasn't designed to be used. Resawing stock into thin slabs is the domain on the bandsaw.

My question is in regards to the next step... The final thinning.

So I resaw a pair of thin slabs so they are bookmatched. But I want to thin them down further and remove any blade scrub. Do most of you do the thinning by hand with a plane, hand held belt sander or bench sander? That leaves a fair amount of work to make sure they are the same thickness.

I've been trying to think of a way to run them through a surface planer to be sure the thickness is the same. Possibly adhere them to a larger piece as a carrier block and pass the whole thing through the planer? Am I trying to over engineer this? I know there is something to be said for hand work, but I have the tools and could surface plane a dozen slabs down to under .1 in the time it takes to hand sand just one.---------------------------------------------------

Love new things that look old, and old things, made to look new again!

-

10-11-2013, 04:12 PM #9No that's not me in the picture

- Join Date

- May 2013

- Location

- Los Angeles South Bay

- Posts

- 1,340

Thanked: 284

Yes bandsaw. I got a jet (horizontal) from Amazon that shipped free, etc. It has a vertical mode and I clamp a piece of stock to get the cutting depth you want as others have said.

I know it's another expense, but once you have that bandsaw you won't know how you did without it, especially if you are cutting metal stock.I love living in the past...

-

The Following User Says Thank You to RoyalCake For This Useful Post:

AirColorado (10-12-2013)

-

10-26-2013, 01:01 AM #10

+++++band saw

I have three but the one I use most is a $130 saw. bands are cheep.

here is a link:9 in. Bench Top Band Saw

This thing is a work horse. It forgives me if I leave it be for months. I clean the rubber on the wheels with a paper towel and my finger nail. I rotate the blade manually and pinch with 220grit sand paper and off I go. I can mill rough barn timber with it. My last set of scales were ash and I also cut camel bone for wedges (smells like a dentist office on steroids after a root canal when cutting bone).

So invest in a band saw you will be glade you did!!!!!Last edited by Fort; 10-26-2013 at 01:04 AM.

"The blade must always be respected"

46Likes

46Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote