Results 1 to 10 of 11

Hybrid View

-

12-23-2013, 07:27 PM #1Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,497

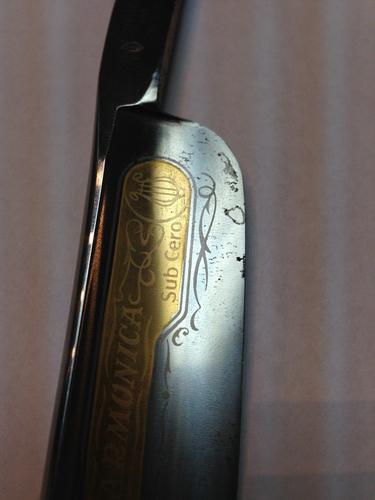

Thanked: 169 Best course of action with a blade like this?

Best course of action with a blade like this?

Worried about that staining on the heel on the back side with such a thin blade and the gold on the front being spared. Not really into losing masses of height on another 14 blade.

-

12-23-2013, 07:28 PM #2Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,497

Thanked: 169

-

12-23-2013, 07:49 PM #3Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,375

Thanked: 3228

You could try 0000 steel wool and a metal polish with the gold wash and etching taped off for protection. That would let you see how bad or good the metal was under that staining. If there is pitting under the staining you may lose a bit of height honing to get to good solid metal.

BobLife is a terminal illness in the end

-

12-23-2013, 07:51 PM #4Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

I would start with this and polishes. Blue Magic first and if I had to go with more abrasive polishes.

The cool thing about this tool is it has backbone like wire but no scratches. Not sure how it would affect the gold but you can easily avoid that with care.

Fiberglass Rust Brush Detail Prep & Cleaning Tool : Amazon.com : AutomotiveGood judgment comes from experience, and experience....well that comes from poor judgment.

-

12-23-2013, 07:57 PM #5Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,497

Thanked: 169

Frustrating. This was clearly used with the factory edge and then put away improperly. Sucks. Dry your nice blades always.

-

12-23-2013, 08:05 PM #6Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

I loaned a young man a straight once to try it out. A week later he brings it back all rusty wanting to know what kind of poo I was trying to sell him. I took it and said, you are a messy baby and I am not selling or loaning you anything you are just going to destroy ever again.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

12-24-2013, 06:45 AM #7Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,497

Thanked: 169

Yeah, loan newbies solingen hardware store blades or give them honed up gold dollars.

-

12-25-2013, 04:53 PM #8

Remember, though, that the little bits of broken glass fiber will get you if you don't watch what you are doing. Lay down newspaper to be folded into itself after work. Wear rubber gloves and assure that you have a clean work area before and after.

I found out the hard way years back!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote