Results 1 to 8 of 8

Thread: D Stoltz Restoration

-

01-05-2014, 02:11 PM #1Member

- Join Date

- Jan 2014

- Posts

- 32

Thanked: 2 D Stoltz Restoration

D Stoltz Restoration

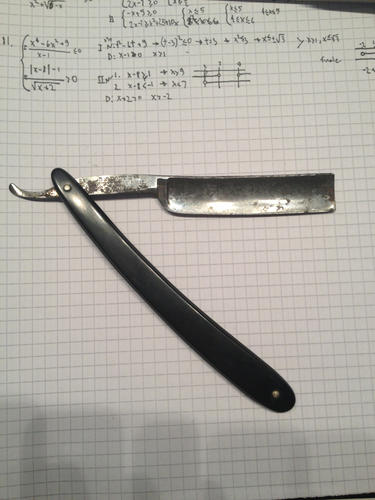

Hey guys I got this razor at an antique store a couple of weeks ago and decided to restore it. Problem is I dont know much about straight razors. So i was wondering is this razor worth it? I would only want to get the stains and the remaining rust off (got most of it off the blade already). The biggest questions I have are how would I get the rust off between the pins and how could i remove some very minor chips without powertools. Here are some pictures:

Also it appears to be the scales are celluloid.

Thanks in advance, TheReaper

-

01-05-2014, 03:30 PM #2

Tried to do this once and it timed out, let's see if I can make it work this time. It's a classic razor, should be fine steel. Looks to be in decent shape. Cleaning the metal can be done a multitude if ways. For a light cleaning this is what I do. 0000 steel wool and WD-40 gets off the bad rust. I then use MAAS metal polish(other will work) with a Q-Tip and toothpicks to get the creases. Keep rotating the tang to get different angles of where it is pinned. This will make a big difference in, but will still leave any pitting. The pitting can only be removed by metal removal (sandpaper and whatnot). As far as the chips in the edge, that requires honing to remove.

Best of luck!The older I get the more I realize how little I actually know.

-

01-05-2014, 03:43 PM #3Member

- Join Date

- Jan 2014

- Posts

- 32

Thanked: 2

Thanks for the info man! I will post the after pics if I can get it done!

-

01-08-2014, 02:44 PM #4Member

- Join Date

- Jan 2014

- Posts

- 32

Thanked: 2

Well got most of it im sanding atm but the pitting us taking forever to get off!

-

01-08-2014, 02:51 PM #5

Yes, removing pitting is a long job, even with power tools it takes considerable time. In the Workshop forum there's a sticky with a lot of info on restoration, including hand sanding. It has tips to make hand sanding easier

I want a lather whip

I want a lather whip

-

01-08-2014, 02:54 PM #6Member

- Join Date

- Jan 2014

- Posts

- 32

Thanked: 2

Thanks man! Ill be sure to check out the post! Hope theres a relatively fast method without powertools since i dont have any.

-

01-08-2014, 02:55 PM #7

That looks like some coarse sand paper. Remember the lower the grit the harder it is to remove the scratches and with hollow blades you don't want to sand to much to make them to thin. If the pitting is too deep might be better to leave it than try to sand it completely away and make the razor to thin to be usable. I find it better to have a decent looking, usable razor than I spotless letter opener.

-

01-08-2014, 02:59 PM #8Member

- Join Date

- Jan 2014

- Posts

- 32

Thanked: 2

I am currently using a100 grit for the pitting. Ill try to sand it some more to see if i can get it all off. If that doesnt work ill try to sand it to a mirror finish even with the pits ahah

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote