Results 1 to 10 of 11

Thread: Suggest me a finish, please!

-

02-08-2014, 12:44 AM #1

Suggest me a finish, please!

Suggest me a finish, please!

My go-to finish has always been super-glue (gorilla brand) because it is so ridiculously tough and the shine is incredible. I've done a set of twin ERN's in Ebony and Maple and finished with BLO, but I don't really like the satin finish. I haven't finished a restore in well over a year, mainly because I get stuck on the finishing portion because super-glue is so time consuming I just get suckered into other projects around the house.

I just got a Grizzly 14" bandsaw and have resawn out some gorgeous scale blanks. I am looking for a finish that is tough enough to handle the wear, but way less painful than super glue to get perfect. Any suggestions are greatly appreciated.

Andrew

-

02-08-2014, 12:57 AM #2

Polymer Composite MAX 116AB, or MAX CLR are very tough!

My friends call me Bear.

-

02-08-2014, 03:22 AM #3Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Why not a natural Finish? such as nut oils and ren-wax,brings out the true glow of hardwoods and is very protective long term.

You do not get the in your face shine that fake plastic finishes impart,you get to see the woods as they really are. JMOCAUTION

Dangerous within 1 Mile

-

02-08-2014, 03:30 AM #4

if you're talking impact, ca and epoxy is about it. if moisture and chemical resistant is what you want, true oil and general finishes wood turners finish are my personal favorites.

Mastering implies there is nothing more for you to learn of something... I prefer proficient enough to not totally screw it up.

-

02-08-2014, 03:32 AM #5

I used boiled linseed oil on those Ern razors, which I love as shavers, but they are just missing that "shine"! I think the ca actually makes the wood pop more than a satin finish does. I wonder if it would be possible to buff out a natural finish?

-

02-08-2014, 04:28 AM #6Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I refinished the top of an old portable sewing machine case last fall and used multiple coats of shellac. Fast and easy to apply. Shiny finish. Worked great!

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

02-09-2014, 09:33 AM #7Senior Member

- Join Date

- Feb 2011

- Location

- Tennessee

- Posts

- 128

Thanked: 24

There you go, I'm with you on that. There is enough junk around made out of plastic nowadays. I'd mix some spar varnish, with boiled linseed oil half and half and cut that mixture, in a small vessel of course, with 2/3 or at least 1/2 mineral spirits. Let the well prepared and finish sanded wood soak up this mixture. Hang to dry and sand off the raised hairs with say 600 or 800. Don't sand away the whole finish only the raised hair fibers. Clean it, re-dunk, soak and dry. Light sand and repeat. Once the wood has the look of having the pours filled, as in the spaces in the fibers are gone, go for the uncut spar varnish. Put on a coat, let it dry and buff it out. Repeat until you get what you are looking for. Or you could try mixing the varnish with pumice powder or rottenstone powder and use as an abrasive. However, that can take some doing to learn the process.

Shellac is great stuff on furniture. It can be easily repaired but is susceptible to water staining. Otherwise, it looks great and classy. Anything with "poly" in the name just plain smells bad in my opinion. But spar varnish, boiled linseed oil, tongue oil and such smell nice to us old...ish guys.

I hope this helps.

Regards

Chasmo

-

02-09-2014, 02:53 PM #8

TruOil. Smooth, glassy sheen (if you want satin you can just give it a light rub with 1k+ sandpaper, 000 steel wool, or an equivalent). Very durable. And, IMHO, far more friendly and forgiving to work with than super glue.

The key is VERY thin coats.

If you do try it, I suggest going with the small 3oz bottle though - it has a short shelf life. Once opened it will start to gum up in about 3-4 months. Also, stand the bottle upside down when storing. That way the skin will form at the 'bottom' of the bottle.

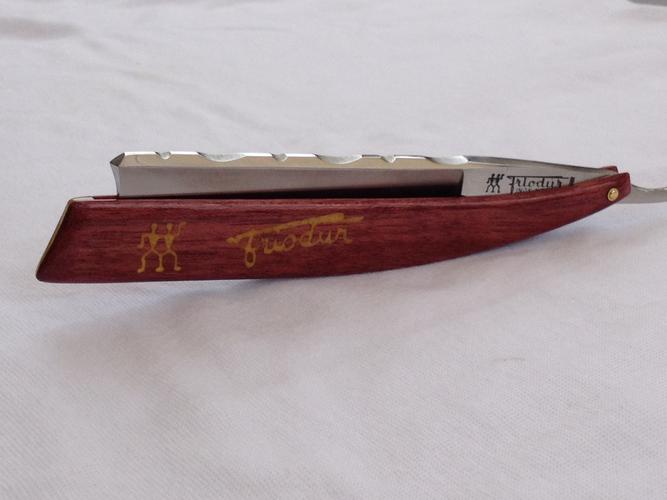

Examples of a TruOil finish on woods such as purple heart, yellow heart, and gabon ebony:

John

John

-

02-09-2014, 08:43 PM #9

I agree with using oils for a more natural look. I use tung oil in varying numbers of wipe on application depending on how porous the wood is.

also, can I just say that you do very clean, professional work malacoda! I'm don't think I've seen any of your other restores on the forum before this... have you started another thread with work you've done? If not, you should share.

-

02-09-2014, 09:40 PM #10

Thanks TwistedOak. I usually post pics in The Gallery. But I usually only do about 3-4 restorations a year, so pics are few and far between (We live in a townhouse and the only space I have for working with greaseless compounds the patio table on our back deck.). I have a couple of Filarmonicas I'm just finishing up (hit them with the greaseless compounds just before winter set in and am just now finishing up the scales on the second one) and will post some pics in a week or two.

John

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote