Results 1 to 10 of 12

Thread: Bone scale shape

Threaded View

-

02-13-2014, 01:07 AM #1Senior Member

- Join Date

- Nov 2013

- Location

- North Carolina

- Posts

- 169

Thanked: 20 Bone scale shape

Bone scale shape

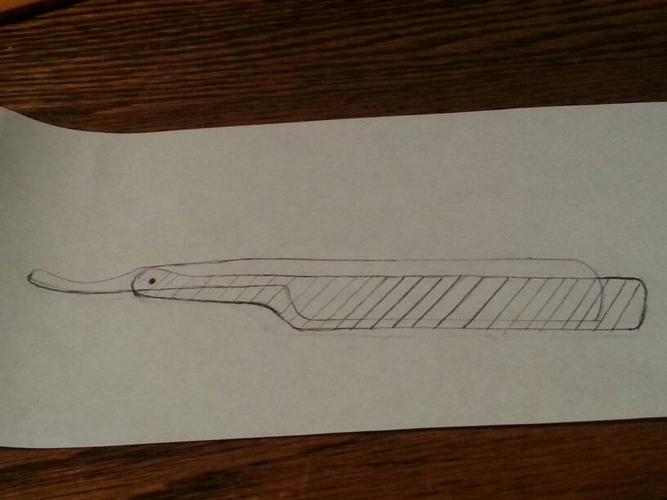

I am working on a set of bone scales for a gold dollar that I have. I went to the pet store and picked up a couple pieces with decent flats for slabs and am trying to come up with ideas for the shape of the scales. The wedge will be bone and I am going to try to install it pin less thinking of stainless washers with nickle pins for the blade. What do you all think of this shape?

Semper Fidelis

Semper Fidelis

Jeremy

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote