Results 1 to 10 of 18

Thread: First Re-scale project!

Threaded View

-

03-18-2014, 04:58 AM #1

First Re-scale project!

First Re-scale project!

I recently got 2 blades in great condition from Ebay, neither one has scales and both need honing, they look like they are both full hollow ground. Both blades arrived today and I've already got a sketch for scales for both of them.

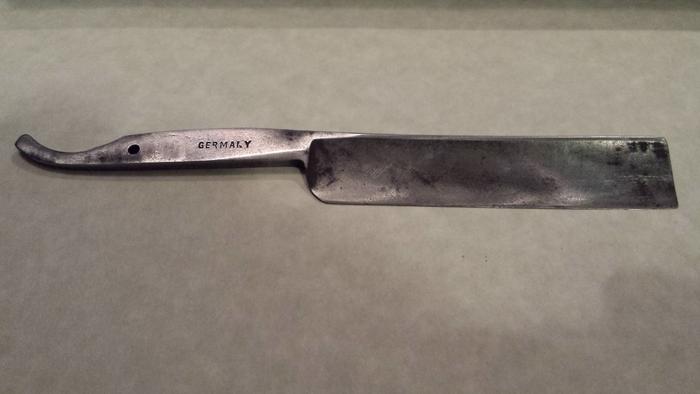

The first is stamped Hibbard Spencer Bartlett & Co. Made in Germany on one side of the tang and Rev-O-Noc on the other. The blade looks almost unused and has an almost mirror finish

For the scales I'm going to use Bois de Rose which is a rosewood from Madagascar.

For the wedge I'm going to use American Holly.

Once it has been sanded and finished, the colors of the Bois de Rose become even more vibrant.

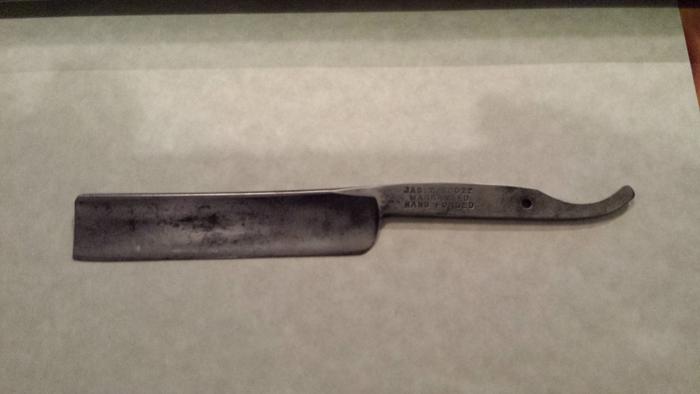

The second blade is stamped Jas. T. Scott Warranted Hand Forged, on one side and Germany on the other. It has some pitting and staining on the faces of the blade, and 2 small patches of rust, though none on the bevel.

I still need to decide on what to use for the scales, but I think I want to use purple heart for the wedge. I am open to suggestions though.

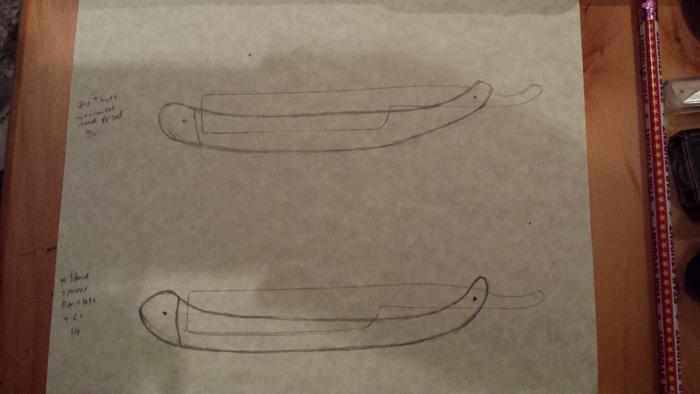

Here are my sketches for the scales. The top one is the Jas. T. Scott, and the bottom one is the Rev-O-Noc

I do have a few questions/thoughts...

First, if anyone knows anything about the history behind these blades I would love to learn about them.

Next, I plan on sending these blades to be honed, since I don't have the tools to do it myself, and I've never done it before. My instinct is to make the scales for the blades first (while they are relatively dull), rather than working with shave ready razors. Good idea?

and last, I know there is a website that has been mentioned where I can get materials for pinning, but my question is, could I find the same materials at a local hardware store, or even someplace like Home Depot. I know I have seen wire stock in craft stores before, so maybe I could even find the washers there too?

Anyway, thanks for any thoughts/suggestions!

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote