Results 1 to 6 of 6

-

03-19-2014, 04:55 AM #1Member

- Join Date

- Jul 2013

- Location

- Calgary, AB

- Posts

- 74

Thanked: 3 So I dropped a razor... it dented the bevel rather than chipped?

So I dropped a razor... it dented the bevel rather than chipped?

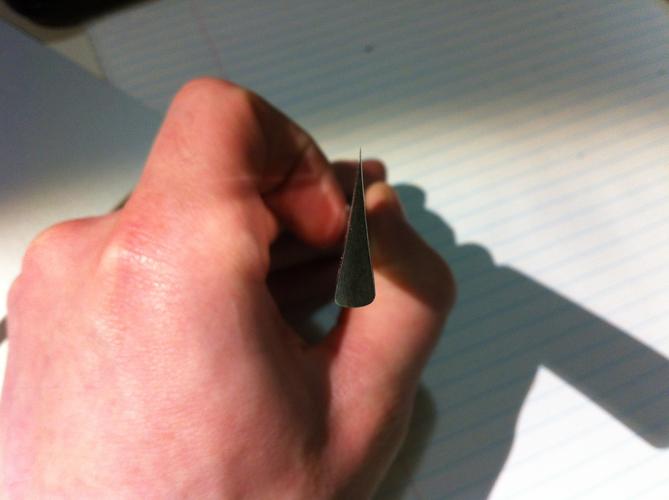

Ok, so I didnt really drop it, so much as my bench grinder caused it to vibrate off the bench it was resting on while I was grinding away on the scales... regardless, when it hit the floor it must have hit a small rock or something... here are some pictures:

Ok so this picture isnt to show the dent but to show what the grind looks like.

My question is whether or not you guys will think I will run into a problem honing this razor in terms of whether or not I am able to hone below the point of the dent. Im concerned the metal at the edge will be so thick that the razor will have to be reground in order to salvage it, due to it being a near wedge. The geometry will all be messed up Im afraid. Do you think its worth even trying?

If the my question is unclear, I will attempt to clarify it. Thanks in advance!

-

03-19-2014, 05:09 AM #2Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

Needs a new bevel is all. Read up on bevel repairs/set. You will have to hone out the dent but it's fixable yes.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

03-19-2014, 06:39 AM #3aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

What I do is take one like that to my well worn DMT 325 and "sharpen" it like I would a pocket knife. What your goal is is to get both sides of the bevel to fresh steel. Take a marker and mark it in the hollow and "sharpen" it with the spine lifted like you freehand a pocket knife until it's almost gone. Pay attention to not change any geometry of the blade and that you are taking equal amounts at the toe and heel of the blade. Tape the spine and set the bevel, then hone as you normally would.

YOU GOT LUCKYSoutheastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

03-19-2014, 06:55 AM #4Member

- Join Date

- Jul 2013

- Location

- Calgary, AB

- Posts

- 74

Thanked: 3

-

03-19-2014, 06:58 AM #5aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

If you wish, however you must note that your blade is how it was designed, not worn. I would keep the original geometry personally. That's a nice old blade by the way, great shavers.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

03-19-2014, 11:10 AM #6

And take a top side look from the spine. Usually you'll see that near the toe is is a little bit wider than at the heel, which means that the natural geometry for the blade is to be wider near the toe than at the heel. If you make the edge parallel to the spine, you're basically screwing up the geometry of the blade. And you'll see it in the bevels because then the bevels will get wider, the closer to the toe you look. Geometry should always be considered in 3D, not in 2D. There is a reason why those big W&B meat choppers are thicker near the toe: it's because they are also wider at that point.

In other words: don't.

This razor was ground by a master craftman and ended up with that shape. Changing the shape will not make it a better razor. If it did, it would have been ground that way.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote