Results 1 to 9 of 9

Thread: Wostenholm options?

-

03-23-2014, 01:39 PM #1Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169 Wostenholm options?

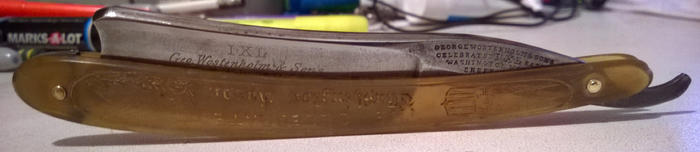

Wostenholm options?

Full album here:

Wostenholm2 Photos by kcb5150 | Photobucket

It weirdly feels very strong still. It obviously isn't ideal. Losing the front scale is completely out of the question. Apart from a duplicate rear using it as a template, any options?

-

03-23-2014, 02:08 PM #2

If you really want to keep them, you must bond them eventually. Use will cause the crack to get bigger. I have unpinned such a razor and encased them in epoxy resin for a friend. I just re-drilled the hole and repined them when they dried. Those scales are virtually indestructible now. Couldn't even tell they were cracked. Another option is to just fix that part of the scale. I would use epoxy resin on it if it were me. Last option is replace, and there are a lot of way to go about doing that

-

03-23-2014, 07:58 PM #3

That's A LOT of work to try to save a scale. I don't know what your rationale is but new

scales would look so much better on that blade. Fixing a crack thru the pivot pin is iffy

even with resin ... and the thickness of the scales i would think, would be greatly increased.

If you want to keep the original scales, wouldn't you want the original pins as well?

Just my 2 cents.

-

03-23-2014, 08:12 PM #4

As mentioned before, superglue is a valid option. It did an amazing job for me on these scales that I broke in half. If it is too awkward to hold together try a mini clamp like one of these:

I got a three pair set, the 4, a 6, and 12 for under $30. The small ones have come in very handy a few times now.Than ≠ Then

Shave like a BOSS

-

03-23-2014, 08:32 PM #5

Am I correct in thinking the scales are pressed horn? If so, I think the epoxy suggestion will work well and is much easier than trying to replicate the colour and texture with a new scale. If you wanted to guard against it opening up you could even cut a channel and insert a peg into the inside scale, bridging the two sides of the crack.

-

03-23-2014, 09:16 PM #6Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169

It's worth saving as it's not at all common to find the detailed scale in such good nick and it looks fantastic in person. We think alike, I was thinking of a dowel as well.

-

05-01-2014, 06:39 PM #7Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169

Having been provided with a lot of data by Bill Ellis and Glen, I was able to successfully bond them.

-

The Following User Says Thank You to kcb5150 For This Useful Post:

williamc (05-01-2014)

-

05-05-2014, 06:42 AM #8Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169

My pinning materials are arriving tomorrow probably so hopefully this holds through the peening process. Going to give it internal washers to hopefully provide a buffer. I also polished my peening hammer's peen to ludicrous levels to avoid having to introduce any polish or anything to that area to smooth things out.

-

05-05-2014, 09:32 PM #9Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169

This was nerve wracking, but it held fast during peening. To the hones!

9Likes

9Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote