Results 1 to 9 of 9

Threaded View

-

04-08-2014, 04:24 PM #1

First set of epoxy coated scales (wip)

First set of epoxy coated scales (wip)

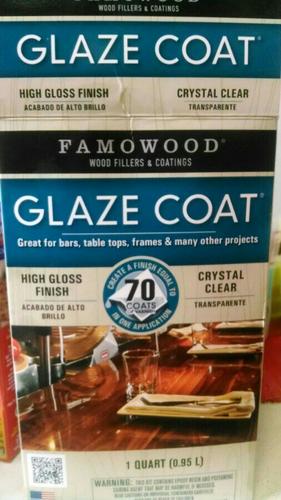

I started my first set of epoxy coated scales Sunday. They are still curing but I really like how they are coming along. They're made from quilted maple with a bar top epoxy. I have a little sanding to do to even out the finish and will apply polycrylic as the final finish.

As always any tips and critique are welcome.

5Likes

5Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote