Results 11 to 20 of 27

-

04-23-2014, 12:30 PM #11

I ended up ordering this one

machine (click)Last edited by miha; 04-23-2014 at 08:23 PM.

-

04-23-2014, 09:55 PM #12

That looks like it would do the job but the buffing wheels are pretty small, perhaps they are for

smaller pieces of metal jewellery rather than bigger jobs ?

I was originally going to buy something similiar to this from an Aussie seller, but he

did not recommend it for extended periods of continuous work polishing straight razors.

He may have been over-cautious though !!

As long as your choice has variable speed control and you let it "rest" frequently and

don't overwork it, you should be fine http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

-

05-08-2014, 11:46 AM #13Member

- Join Date

- Jul 2013

- Location

- Netherlands

- Posts

- 50

Thanked: 3

Never tought of dentistry equipement, gonna look into a mini buffer/grinder as soon as my shed is complete.

-

05-08-2014, 11:59 AM #14

mine arrived,.. form what i had an opportunity to test it (had to buy 100w 220V to 110V "adapter" first) it looks like nicely done. The only problem is that I bought 2 types of buffing wheels (see the pic below) one the more "fluffy" one has a small hole, sewn with leather and it stays on nicely, but the more dense one with a 1/2" hole (without the leather, the wheel on the left) is almost too big for the conical screw thingy that holds it in place, temporarily I put on the machine side a plastic tie and some rubber bands on the right in order to stabilize it at least a little (kind of a macGiver solution

just more dangerous

just more dangerous  ) , I plan to sew the thick leather circles on and hope it will do the work (I'll add some epoxy glue in there as well probably).. if some one has a preposition how to solve this it'd be great

) , I plan to sew the thick leather circles on and hope it will do the work (I'll add some epoxy glue in there as well probably).. if some one has a preposition how to solve this it'd be great

-

05-08-2014, 12:54 PM #15

If I'm not badly mistaken the wheel on the left is designed to go onto a round mandrel with washers on either side to fasten it and a nut to tighten it down. It is not a tapered leather reinforced hole because it is made for a different system of mounting.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

05-08-2014, 01:27 PM #16

you are of course right, and I knew it (well sensed it

) and it is all my fault, buuuut as I was extremely limited with the time of delivery (3 days from order to delivered) I only used amazon items for which I was sure would arrive in time, as a result of this I ordered the wheels on the left as well, knowing they have a bigger hole and hoped it'd work as well (they were app 10 euro I think, so I would still live if they wouldn't work :d ).

) and it is all my fault, buuuut as I was extremely limited with the time of delivery (3 days from order to delivered) I only used amazon items for which I was sure would arrive in time, as a result of this I ordered the wheels on the left as well, knowing they have a bigger hole and hoped it'd work as well (they were app 10 euro I think, so I would still live if they wouldn't work :d ).

At the moment I'm trying to save the situation of having 3 wheels that I'd use the most (denser) that aren't really fixed on the system I have at the moment as they should be...

As far as I understand I have 2 options: 1. buy the attachment with the washers (that I don't really know what it's called in english if I'm honest) and 2. try to reinforce the hole with leather and maybe some epoxy on the inner edge and hope it'd stay on the spindle, or maybe a variant of the point 2, I just get another, a bit bigger conical threaded spindle (any advices where to buy a cheap one?) that would work with a bigger (leather reinforced) hole?

-

06-12-2014, 08:09 PM #17

hey guys,... I am thinking of order some more 4" buff wheels, with the smalled leather reinforced hole this time

... can someone recommend me a good cheap US online resource for these wheels, I was thinking of getting like 2 coarse, 4 medium and 4 soft wheels (excuse my absence of knowledge for the proper naming of the buffs) .. do not get this as me being lazy it is just to avoid any mixups, but if someone wouldn't mind posting links of the wheels I am asking that would be very helpful (I'm going to order online to a friend in US probably).. thanks to a (for now) unknown helper

... can someone recommend me a good cheap US online resource for these wheels, I was thinking of getting like 2 coarse, 4 medium and 4 soft wheels (excuse my absence of knowledge for the proper naming of the buffs) .. do not get this as me being lazy it is just to avoid any mixups, but if someone wouldn't mind posting links of the wheels I am asking that would be very helpful (I'm going to order online to a friend in US probably).. thanks to a (for now) unknown helper

-

06-12-2014, 08:31 PM #18

Miha no real idea but I thought the buff wheels are different hardness & materials types & the grit is from applying pastes etc to them for different effects

note I have no current buff myself but looking for an option for the future & love this thread for the infoSaved,

to shave another day.

-

06-12-2014, 08:53 PM #19

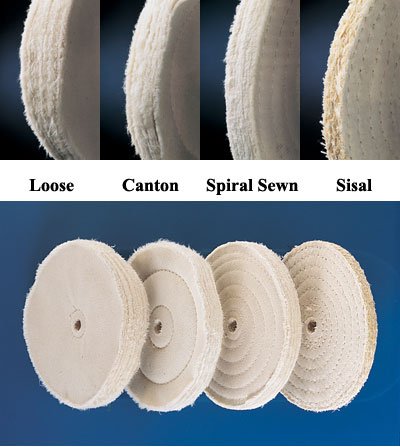

hey Substance... that is correct, but than on the other hand you have different density and different fabrics of the wheels, and this is what my question is about,.. i am adding a pic from the net for better understanding .. for now i am only having polishing compoundy, but owuld probably be a good idea to get some greasless compounds (those go on sisal wheels).. an this is also another (I know stupid) question, which would be the eg starter kit for greasless compounds you would recommend?

the different wheels.. mind that there are also different fabrics option not shown here..

-

The Following User Says Thank You to miha For This Useful Post:

Hirlau (06-12-2014)

-

06-12-2014, 11:09 PM #20

I do remember there was a recent thread about just this, where to get compounds & what buff to use with what compounds etc & I am sure Casewell was in the list as an was an option as well as some other sources and info

not sure which tread it was but a search should find it as it was only in the last couple of months I am sureSaved,

to shave another day.

32Likes

32Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote