Results 1 to 10 of 67

Thread: Matching up scale halves

Threaded View

-

06-02-2014, 11:37 PM #1

Matching up scale halves

Matching up scale halves

A decent old pair of ivory-scaled Sheffields, one with a cracked scale which needs replacement

After disassembly of the damaged razor, a hard look thru the parts bin produces the only viable candidate. I needed something larger, not smaller, so as to match the 3 remaining scale halves.

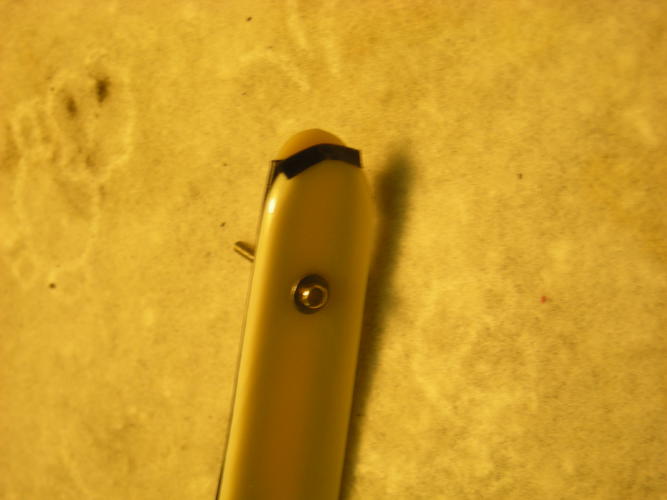

Finding a donor with the exact pin hole spacing is a dream. As you can see, they were off by about a half-hole. Best it was going to get!

A small, pointed jeweler's file slightly slotted all 4 holes in the right directions until the holes aligned.

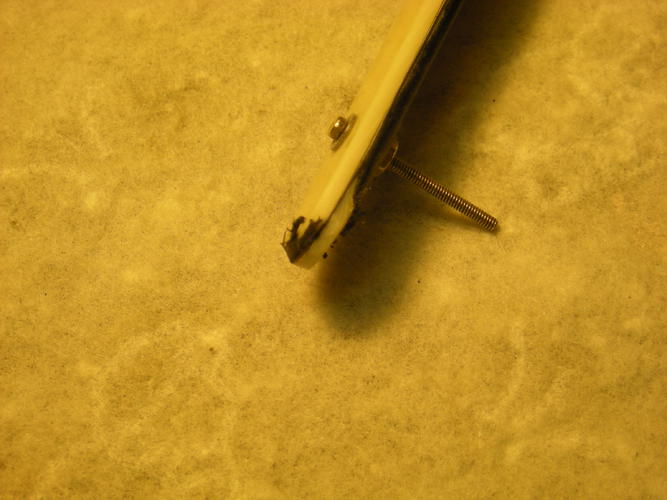

Back apart, the parts to be sanded down to were taped. most on the original scale, the tip of the replacement scale. Then, bolted back together.

Using a Dremel fine drum sander, Low speed sanding smoothly as possible till the tape was hit evenly everywhere. I do this with a fan blowing across the work, taking the stinky dust away!

Unbolted the halves again, removed tape. Looking pretty decent!

Bolted back together. Here is where the hand sanding, matching contours, polishing, more contour sanding comes in!

After doing my best, unbolted, smoothed a bit and polished!

The tips of the original-scaled razor are slightly taller at top at this point.

A good match for the other set of scales, save a bit shorter on the top. The other razor will be completely disassembled and the tips matched to the repaired set using the same technique. Probably best to have unpinned everything as my collarless peens never quite seem to match the factory ones!

No more ivory is being made, so saving and using scale halves is the only way I have to replace them. As long as the halves last, that is!

This works well for me as trying to do more exact work such as in pairs. I have used it on bone and Bakelite as well.

Blue masking tape works great too. On single razors, sanding some here on one side, there on the other, usually makes a slightly different scale than either started as, but more often, turns out pretty good!Last edited by sharptonn; 06-02-2014 at 11:39 PM.

"Don't be stubborn. You are missing out."

I rest my case.

-

The Following 26 Users Say Thank You to sharptonn For This Useful Post:

bongo (06-03-2014), Cangooner (06-03-2014), carrolljc (06-04-2014), Chevhead (06-03-2014), cudarunner (06-07-2014), engine46 (10-01-2014), Geezer (06-03-2014), gugi (06-05-2014), JimmyHAD (06-04-2014), Martin103 (06-04-2014), MikeB52 (07-15-2015), Neil Miller (06-03-2014), nipper (06-04-2014), onimaru55 (06-03-2014), RezDog (06-03-2014), RickyBeeroun222 (06-08-2014), silverloaf (06-04-2014), spazola (06-03-2014), Splashone (06-03-2014), Steel (06-03-2014), Tarkus (06-04-2014), Trimmy72 (06-03-2014), Wolfpack34 (06-02-2014), WW243 (06-06-2014), xiaotuzi (10-20-2016), Zephyr (06-03-2014)

139Likes

139Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote