Results 11 to 13 of 13

-

08-28-2014, 10:28 AM #11Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

Blimey - 5/64ths is so close to 1/16th that there isn't an issue - 1/16th rod is so commonly available!

Ignore the tiny extra 1/64th of an inch and say it is 4/64ths for a sec, that's the same as 2/32nds which is the same as 1/16th, so you have a hole that is 1/64th of an inch wider than 1/16th of an inch. That 1/64th is a tiny fraction - just one part of an inch that has been divided up into 64 equal pieces.

In metric, 1/16th is not even 1.6mm - quite - it is 1.5875mm. 5/64ths is 1.9844. That's a difference of 0.3969mm. Impressively large to a gnat, maybe...

Fully anneal the rod and you can get a wider than usual flare/mushroomed end - no problem.

As for the damascus pattern being printed on, I too have quite a number like that. I also have a lot of the pattern hammer welded type. With an early le Coultre or one of the other makers - several used twisted steel wire (ie hawser type braid) - then it is a proper pattern, not an etched one.

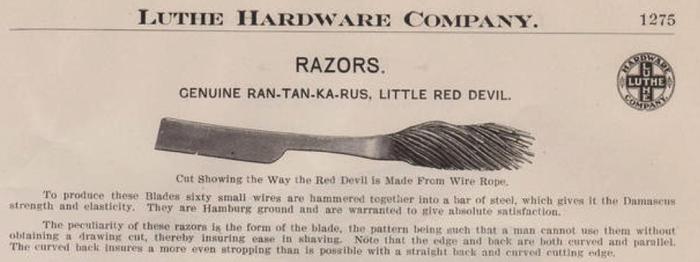

After some time even le Coultre stopped using his special watch springs to make razors, and later ones were stamped finest Sheffield Steel. However, the practice of using steel wires in the form of 'steel rope' remained, as withness this ad for the Ran-Tan-Ka-Rus razor"

Like Pixel hints, there is a world of difference between an etched pattern and a formed in the steel pattern, but visibility is not one of those differences. True, an etched pattern will disappera for ever, but without the proper treatment and just normal grinding and polishing, a made-in-the-steel pattern is pretty invisible too - the difference is that the latter can be brought back (with the use of certain acids) whilst the former cannot.

Regards,

NeilLast edited by Neil Miller; 08-29-2014 at 12:58 AM. Reason: typo

-

-

08-28-2014, 10:11 PM #12

Useless fact, in Japanese they call the wavy lines nioi and the signature of the sword smith is the hamon which is wavy line above the fold pattern.The way they do it is amazing, they take finely ground slurry and make the pattern free form on the blade before it has its final firing.This slurry protects the edge from damage in the final firing, it is a bit thinner on the edge side and thicker as it goes toward the spine.This varies the proving of the steel through the length and width of the blade giving the Katana its unique properties.Now how do we get this to apply to a straight?

A good lather is half the shave.

William Hone

-

08-28-2014, 10:39 PM #13

-

The Following User Says Thank You to Substance For This Useful Post:

Crackers (08-29-2014)

27Likes

27Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote