Results 1 to 8 of 8

24Likes

24Likes

Thread: Need Help with a C-MON/FILA restore

-

09-26-2014, 08:44 PM #1

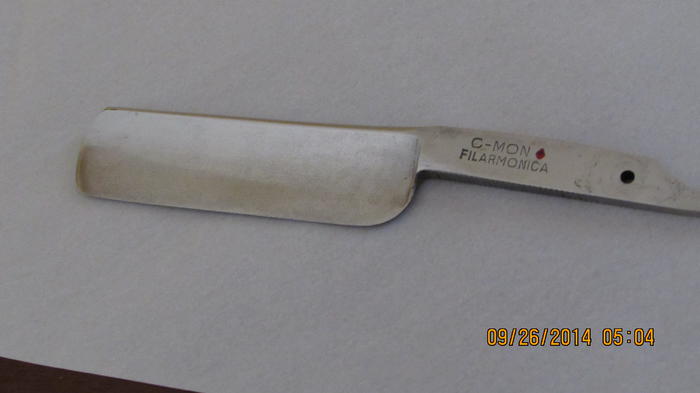

Need Help with a C-MON/FILA restore

Need Help with a C-MON/FILA restore

Here is what I got. I am thinking I need to sand more get down to clean metal. I am too scared to try greaseless on a full hollow. Any input would be helpful. I just see pits and residual rust left overs .My thoughts are I didnt go down deep enough to remove all the gunk.

-

09-26-2014, 10:11 PM #2

It might be one the find the limit of enough is enough

I'm sure other can give real advice on how to go but I would probably leave as it my self in fear of buggering it up alsoSaved,

to shave another day.

-

The Following User Says Thank You to Substance For This Useful Post:

ultrasoundguy2003 (09-26-2014)

-

09-26-2014, 10:43 PM #3

Fine sandpaper and lots of rubbing. You seem to have some slashes from lower grits still, so stay with the finer stuff, up and down.

The wet/dry and WD40 seems to work best. You have come a long way! It will be worth it! "Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

The Following User Says Thank You to sharptonn For This Useful Post:

ultrasoundguy2003 (09-26-2014)

-

09-27-2014, 12:11 AM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

the progress is looking really good, I'm with the others and think hand sanding is best. I might just be saying that because I don't have a lot of buffer experience, so it makes me extra careful about when to stop buffing. I may also cry if I messed up that blade. I mostly hand sand and actually use the buffer very little. You can work the last little bit of black out with steel wool and polish, it does leave the pits because it doesn't remove the steel. I did mess up an extra hollow hand sanding too, you can still go to thin. Some blades don't really have a lot extra to play with.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

ultrasoundguy2003 (09-27-2014)

-

09-27-2014, 05:24 PM #5Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

You have to use the force Luke :<0) If your worried about going to far then stop with the heavy grits. The lengthwise lines have got to go but I would use as light a grit as you can going up and down the blade. Doing little circles with the next fine grit to make sure you got alllll the previous grit marks out. I find those length wise scratches harder to get out for some reason so I avoid those strokes after I am sure I have gone as far as I want with pit removal. They don't look so bad if you get all your scratches out. The finer grit you go to the easier to get to shiny which means less time on the buffer for that phase.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

The Following User Says Thank You to 10Pups For This Useful Post:

ultrasoundguy2003 (09-27-2014)

-

09-27-2014, 06:31 PM #6

Thank-you Sir, I will do as you recommend.I appreciate you weighing in. I want to try shaving with this one first, then back to the workshop it goes. I couldnt ask for a better mentor. Oh Obe Wan . I must learn the way to shiny clean metal. The light saber sanding stick is been getting a work-out.

-

10-13-2014, 12:11 PM #7Junior Member

- Join Date

- Sep 2014

- Location

- Slovenia

- Posts

- 27

Thanked: 7

Wow, you have done a good job so far! Thumbs up! Looks awesome.. like others said, just get the previous marks out and do it by hand...slowly ..steady and a little at a time..it's a hard job but the end result will be so rewarding. I had to left some black spots on my vintage ones that i restored because they were to deep, but your razor looks like you could make it mirror finish. Let us know how it turned out. Best of luck, Stick

-

The Following User Says Thank You to Stick For This Useful Post:

ultrasoundguy2003 (10-13-2014)

-

10-13-2014, 12:53 PM #8

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote