Results 1 to 10 of 13

-

10-06-2014, 01:30 AM #1

From Bowie knife to Kamisori razor

From Bowie knife to Kamisori razor

I decided to try a simple fun project using what I had laying around the workshop today. I had a beat up old rusty Bowie knife that I bought as a kid and wanted to see if it would make a usable razor.

Here's what I started with:

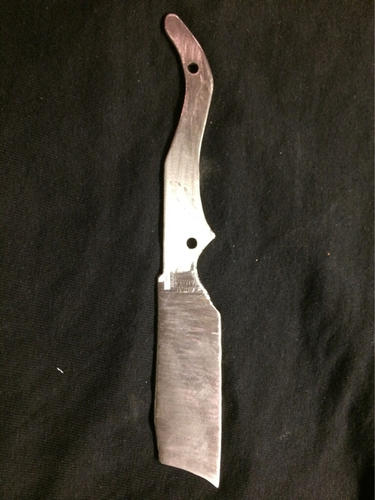

And after removing the handle and drawing on the pattern:

Finally, after some judicious grinding and initial polishing:

So, now I just need to find me some larger grinding wheels because I want a full hollow ground blade...

After that I will hone it and try it out!-Brian

-

10-06-2014, 01:58 AM #2

,,,,,,,,,,,,,,,,

Somebody call the Bowie Abuse Hotline !!!!

-

10-06-2014, 03:21 AM #3Senior Member

- Join Date

- Feb 2014

- Posts

- 225

Thanked: 36

lol. cant wait to see the final product

-

10-09-2014, 02:11 PM #4aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Wow, interesting re-sourcing of material. After you get this razor better profiled, smoothed up with sandpaper, and hollowed out you will need to have it properly heat treated and HOPE that the steel has enough carbon in it to be hard enough to hold up to a razor edge. You see, knives are made to not be as hard as a razor as they have different tasks assigned to them. A knife as hard is just too hard and brittle & a razor as hard as a knife can't hold an edge as it's too soft...speaking in general terms.

Next thing is that you can't grind your blade too thin at the edge or it will warp during heat treatment, you have to do a final grind after heat treatment...this can't be done with a conventional 6 or 8" grinder that's spinning over 3k rpm's. I have used a grinder to do an initial and final grind, but it was a wet grinder from Sears: http://straightrazorpalace.com/forge...ake-razor.html . To give you an idea of my final grinding speed with fine sandpaper, my 2x72 grinder is turning an estimated 5 feet per second.

I'm not saying your project is a loss and you destroyed a perfectly good bowie (I thought it though), I'm just saying you have a lot more work in store to make it a useable razor. I will help you the best I can if you will follow my lead. The unknown is: Will the blade get hard enough to take a razor edge.Last edited by ScottGoodman; 10-09-2014 at 02:13 PM.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

edhewitt (10-09-2014)

-

10-09-2014, 02:14 PM #5aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

By the way, you are just a couple hours away from me...I live north of Paris, TX about 20 miles off hwy 271

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

10-09-2014, 02:32 PM #6Senior Member

- Join Date

- Nov 2010

- Location

- Pequea, Pennsylvania

- Posts

- 2,290

Thanked: 375

I think you just sucked the fun right out of this project Scott HA! LOL

CHRIS

-

10-09-2014, 03:38 PM #7aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

yes and no. If we were to get together at my place we might be able to both educate him and save that RSO

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

10-09-2014, 04:29 PM #8

Project update

Project update

Thanks all, for your comments, and especially Scott for the detailed advice. I was hoping to get just such info as you provided, so again, I appreciate it.

Now, let me share where I am at with this project... I only have an hour or two here and there to work on such things, so this is what I do to blow off steam after the kids are in bed. If I lose an ancient bowie knife that wasn't doing anything but rusting in the bottom of my tool box, then it's no big deal. If I gain a workable razor and have that good feeling that comes from using something home-made, so much the better!

After rough-shaping I polished the body of the razor to a satin finish (about 800 grit), and then I cut jimps on the handle for better grip. I then honed the edge to a bevel of about 12 degrees or so and all the way to a 3 micron grit, so it was fairly mirror smooth.

Not having much in the way of tooling I haven't been able to grind the hollow yet, but I was anxious to try it out anyway before investing any more effort in this curiosity. I paid special attention to the sparks during grinding to get a rough idea of the carbon content of my steel. Based on published charts I very roughly estimate the carbon is about 0.5 to 1%. If I look up similar knives by the Colonial Company I guess that mine has 440 c stainless steel, Rockwell 58-60, which has a minimum 0.95% carbon, but no doubt hardened more for durability than for shaving purposes. In any case, it shaved well this morning, but I realize without the hollow and without hardening it's probably not going to be much use for very long.

Now, for some pics...

This first pic shows one side of the razor at it's current stage of completion.

This is the other side,

and this is the spine.

Finally, an edge-on view shows that it is a simple, thin wedge, at this point, not a hollow.

But, of course, that's what you get when you grab an old knife like this rather than the thicker steel of a real razor.

So, if I feel ambitious and no other project intrudes I may take this to the next level and actually harden it further by building some kind of a home forge, probably involving a coffee can with some plaster inside and a propane torch, or a forge made from some fire bricks, charcoal, and a bellows that I have for my fire place. I will need a magnet handy to tell when I've reached the austenite phase around 1500F or so, and then quench in oil, followed by tempering in my kitchen oven around 350C for a couple of hours. I will then need to buy an old used belt sander or build a grinder that can turn slowly, as advised by Scott, and return to the honing process again because by then I will have lost my edge and oxidized to a depth of a few mils.

Alright, this is fun stuff. I may post more... Cheers ya'll, and thanks for the invitation to pay a visit and learn even more about the craft of DIY razors. I've seen some really nice ones on here.-Brian

-

10-09-2014, 05:59 PM #9

Sorry, one correction... My honing angle is really about 20 degrees.

-Brian

-

10-09-2014, 06:06 PM #10

Yep I was going to say that's a really big bevel

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

20Likes

20Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote