Results 1 to 10 of 10

Threaded View

-

12-12-2014, 06:43 PM #1

Almost everything you ever wanted to know about working with horn scales.

Almost everything you ever wanted to know about working with horn scales.

First and foremost, I never would have done any of of the things I describe in this post if it weren't for discussions and encouragement from my friends here.

In particular, Neil Miller's excellent posts about historical horn dyeing lead directly to my recent dye experiments.

- Neil's overview of horn work

- Detail on dyeing processes in the past

- Some more about caustics in horn work

- Bleaching horn

The scale vise technique I'll discuss is a slightly modified version of what Wolfpack34 uses.

And finally, my method for centering a problematic razor came as a result of discussions with Wolfpack34 and 10Pups while sitting around and talking razor stuff. It was generally considered to be crazy.

Now, without further ado:

Fun tricks with horn: flattening warped scales!

One of the most common problems you'll run into with old horn scales is bad warping.

Using this method, it's possible to flatten even badly warped scales.

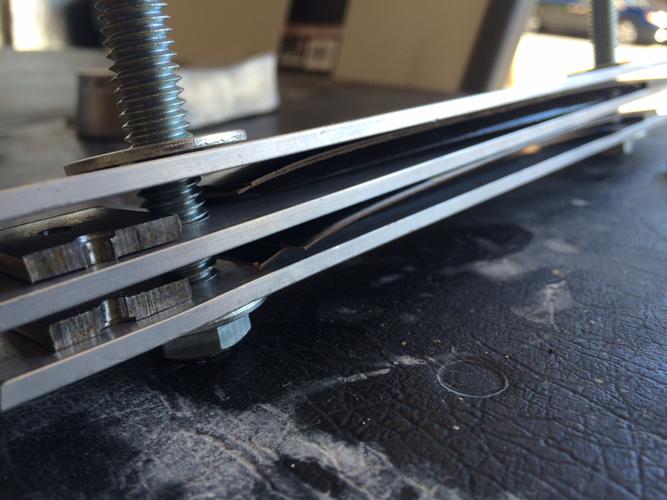

Here's a picture of what I use:

In the picture are three long strips of relatively thick aluminum bar, two bolts, some pieces of steel bar used as spacers, large washers, nuts, and some strips of cardboard from a box of soda.

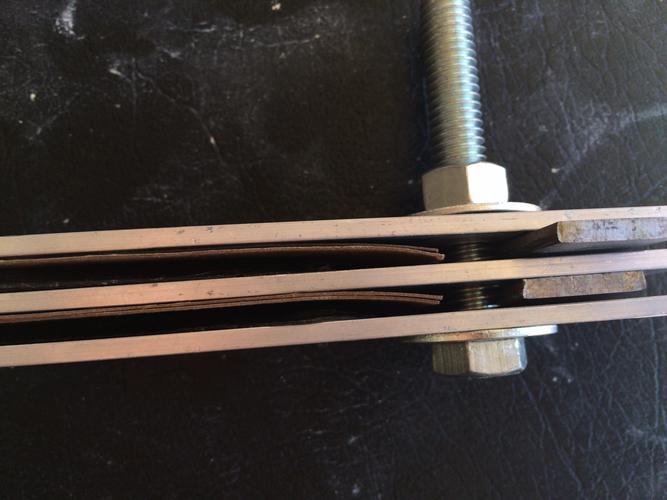

It all gets sandwiched together like this:

The horn scales are placed with the inward facing surface flat on the aluminum. I put two strips of cardboard on top of that, then the next layer of aluminum bar, the other scale, more cardboard, etc.

Here's where the ideas at work are useful to understand.

We're going to be baking this.

The goal is not to exert a great deal of pressure on the scales -- doing that would put dents in them. Instead, it's to use just enough pressure to get them to lay flat. The steel spacers are doing most of the work here, and the cardboard provides a little bit of 'soft pressure'. It won't press into the scales, but it will provide just a little bit of extra-gentle pressure.

Once it's sandwiched, I bolt the whole thing together, like this:

After that, I take the whole vise and put it in my toaster oven. I set the temperature to 240 degrees, turn on convection and run it on a 10 minute timer. I suspect this works best if you put the vise and scales in while the oven is heating so that it's brought to-temp a little more gradually.

240 degrees (that's Fahrenheit) isn't significantly warmer than boiling water. My automatic hot water pot for coffee and tea dispenses water at 220. It's not hot enough to scorch the paper.

But it is hot enough to make the horn a little more plastic.

Once I take it out of the toaster oven, I put it immediately into the freezer for a some variable amount of time. Working on the 'for a while' principle, basically I take it out of the freezer when I remember to -- typically about 2 hours later.

Then I let it sit for 12-24 hours at room temperature before taking the vise apart.

This technique has been effective every time I've used it (probably 10 times now). Occasionally, a set of scales will require a second run through, but none have needed a third (and I've done this to some very badly warped scales).

This technique even works on ornately pressed scales without damaging the design.-Zak Jarvis. Writer. Artist. Bon vivant.

-

The Following 22 Users Say Thank You to Voidmonster For This Useful Post:

32t (03-10-2015), Baxxer (12-13-2014), criswilson10 (12-12-2014), DoughBoy68 (12-12-2014), engine46 (02-16-2015), Geezer (12-13-2014), Hirlau (12-13-2014), jfk742 (07-02-2021), JimmyHAD (12-13-2014), Lynn (12-13-2014), manah (01-27-2017), MattCB (12-12-2014), Ranzor (12-13-2014), rolodave (12-12-2014), ScienceGuy (12-19-2014), sharptonn (12-13-2014), Splashone (12-12-2014), sqzbxr (02-07-2016), Substance (06-21-2015), Thaeris (12-15-2014), tintin (08-20-2017), Wolfpack34 (12-13-2014)

39Likes

39Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote