Results 71 to 80 of 156

Threaded View

-

01-05-2015, 10:58 PM #1

Show The World How You've Modified Your Tools To Work For What You Needed/Razors etc

Show The World How You've Modified Your Tools To Work For What You Needed/Razors etc

Hi All,

I had once again recommended GSSIXGUN'S Wonderful Video on Pinning for a newbie wanting to learn more about pinning a razor and even though I've seen it many times this time when he talked about his 'Modified Tack Hammer' as his final pinning hammer I decided to start this thread so that others can show how something either never designed for working with straight razors were transformed so that they would

Here's a few of mine.

Since the chasing hammer would be mostly used with the Ball end it didn't feel right in my hand so I removed the head and reattached it 180 degs from where it was originally.

The 8 oz ball peen hammer was too long while tapping on a pin punch so I shortened it and the factory rubber end piece was placed in very hot water and then quickly dried and slid on. It now fits Very tightly and so far hasn't given any indication of coming off very easily.

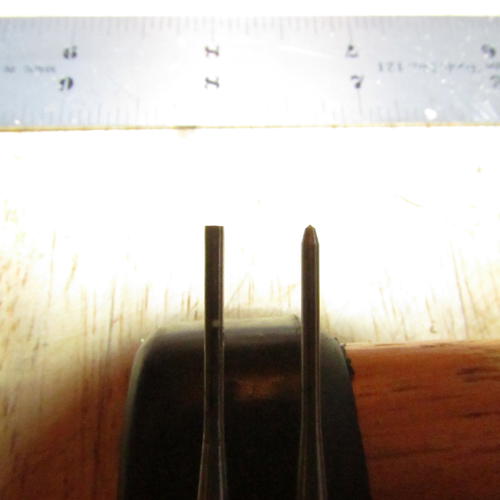

The 1/16" pin punch would skid while trying to drive an old pin out so I made it into a self centering punch. It also helps to start a 5/32" drill and keeps it from wondering. I have another pin punch that is unaltered so you can see the difference.

I'm sure that I'm not the only one out there that has modified a tool to work on a certain application.

I believe it was Kris Kristofferson who wrote: You Show Me Yours and I'll Show You Mine. Well I've shown you some of mine, now show us yours.

Any takers? Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following 5 Users Say Thank You to cudarunner For This Useful Post:

jnats (02-12-2016), MikeT (08-02-2015), Utopian (02-01-2015), walleyeman (01-08-2015), Willisf (01-06-2015)

616Likes

616Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote