Results 1 to 3 of 3

-

01-28-2015, 05:22 AM #1Junior Member

- Join Date

- May 2014

- Location

- United States

- Posts

- 11

Thanked: 1 Restored/Re-scaled H.M Christensen

Restored/Re-scaled H.M Christensen

I got luck on this Ebay purchase (cheap!). I had been looking for an H.M. Christensen because from what I understand H.M Christensen was a Danish immigrant as are both sides of my family. Found this and when it showed up it was in much better shape than I expected. Nice geometry and no deep pitting. I really only cared about the blade as I wanted a razor to work on for my first restore/re-scale.

Here is what it looked like upon arrival.

I un-pinned it and polished the blade with a progression of 400-800-1000-1500 wet/dry sand paper using WD-40 as a lubricant. It cleaned up relatively well but does still have some patina. After sanding I rubbed with Mothers Mag & Aluminum polish.

I honed it with a Norton 4K/8K. Ideally I would have had a 1K, but at the time I don't. It took some work with the 4K, but I got it to a point where it would easily pop arm hairs. More work back and forth from 4K to 8K and I felt it was close to ready.

Scales cut and started finishing. I used Bocote wood planed to 3/16" thinckness. For the finish I used 2 coats of Shellac followed by Minwax Fast Drying Polyurethane. The Shellac was to allow proper adhesion and drying of the poly since Bocote is such an oily wood. The wedge was made from Walnut.

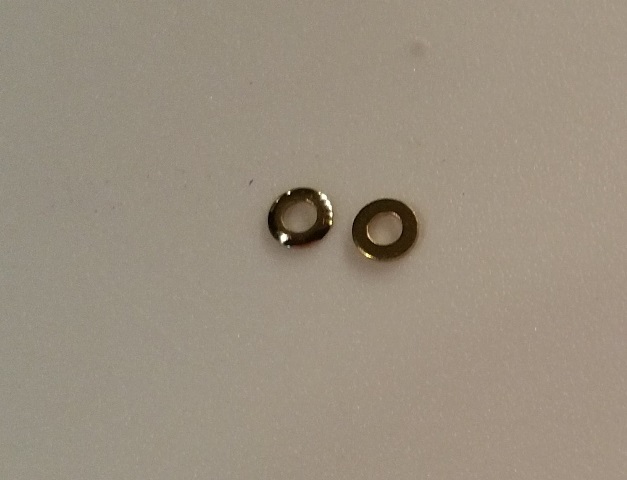

Polished my Brass #0 washers using the suggestion from this thread. Polished on the left, original on the right.

Pinned and ready for the strop!

I shaved with it Sunday and it gave a great shave! I love the 11/16 blade, it is much heavier than the 4/8 Wosty I had been using and feels better in the hand.

Things I will do differently next time:

1. Buy a 1K hone

2. Use a scale thickness of 1/8" rather than 3/16"

3. More attention to detail on the wedge, it doesn't fit exactly flush with both scales.

4. Test different finishes, not sure how I feel about this poly yet...it feels thick and plasticy.

Thanks for reading!

-

01-28-2015, 05:51 AM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

The top view picture is fairly dark and it is hard to see all the details in it. Is the blade to one side? I think you are right with using thinner stock for your scales. I have not done many wood scales, in part because I am fixated on horn and because I don't have a lot of selection where I live. I have to say for a first project this one looks like it came out pretty darn good. Like everything else in life we get better with practice. Good job!

It's not what you know, it's who you take fishing!

-

01-28-2015, 05:58 AM #3

Very nicely done!

I have a couple all original HM Christensen's, a 5/8 round point and a 6/8 square point in really nice condition. Both are excellent shavers but what else would you expect from US steel. The best thing about razors made in the USA is they are readily available and can be bought at very reasonable prices especially for a quality razor.

FYI, Tung Oil works great on oily woods like Bocote and Cocobolo.Last edited by DoughBoy68; 01-28-2015 at 06:03 AM.

"If You Knew Half of What I Forgot You Would Be An Idiot" - by DoughBoy68

2Likes

2Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote