Results 1 to 10 of 16

-

01-29-2015, 02:27 AM #1

Need help on best route to go with removing a chip from 200 year old straight.

Need help on best route to go with removing a chip from 200 year old straight.

I recently just picked up and old straight from a certain auction website. The thing is amazing. I just won it so it won't be here any time soon but I am already planning on how to tackle it. I've honed chips out before but never on this shape of a razor and this old of a blade. I currently have a 325/1200 Duosharp, Norton 4k/8k, and a Naniwa 12k. I'd hate to breadknife but due to the flush tang I'm not sure I could just hone it out. Any help and guidance is greatly appreciated. I'm not sure if this is allowed but does anyone know about how much it'd cost to get this honed and the scales taken care of? Would hornoxy work for this? Thanks greatly! I'm literally drooling about the thought of shaving with this thing.

-

01-29-2015, 02:57 AM #2

Welcome to SRP. Cool stub tail. That is circa 1790s or so. I got a chip out of this one honing it like a pocket knife, with the spine off of the stone. When the chip was about gone I put a layer of tape on and began setting a proper bevel. If you want to send it out here is member services where you can inquire as to cost ;

http://straightrazorpalace.com/class...wcat.php?cat=4

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

The Following User Says Thank You to JimmyHAD For This Useful Post:

StraightOverload (01-29-2015)

-

01-29-2015, 03:07 AM #3Senior Member

- Join Date

- May 2014

- Location

- Bryan, TX

- Posts

- 1,251

Thanked: 228

Nice catch!

Mike

-

The Following User Says Thank You to mglindo For This Useful Post:

StraightOverload (01-29-2015)

-

01-29-2015, 03:12 AM #4

I'd rather do it myself but I am certainly open to sending it out to someone more experienced if deemed necessary. I don't really enjoy working on scales so it may make it out for at least that. The thing that worries me the most is how close the chip is to the transition into the tang. It seems like it would be easy to take it down too much and ruin the profile of the blade.

-

01-29-2015, 04:44 AM #5Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yes, nice find.

I never understood the hesitance of bread-knifing an edge. You will remove exactly the same amount of material, no matter how it is done. You have to get to the bottom of the chip.

Actually I think you have more control by bread-knifing to almost the bottom of the chip.

I hold the razor edge up, spine on a piece of foam, to keep from dancing, then run a 300 grit diamond file or plate, (I have some EZE lap 2X6 in plates that work well for this) and run the file at 90 degrees to the edge to remove steel. As thin as the bevel is, it goes quickly, you have a lot of control and most importantly, you can see what you are doing, as the edge is visible at all times.

I then do 45 degree, spine off the stone honing, to start a bevel on a 1K diamond plate, and get the edges to almost meet, then hone normally on a 600 or 800 stone with 2 layers of tape and switch to a 1K stone, once the edge begins to come together.

Once the chip is completely removed you can go to 1 layer of tape, if you wish.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

StraightOverload (01-29-2015)

-

01-29-2015, 06:50 AM #6

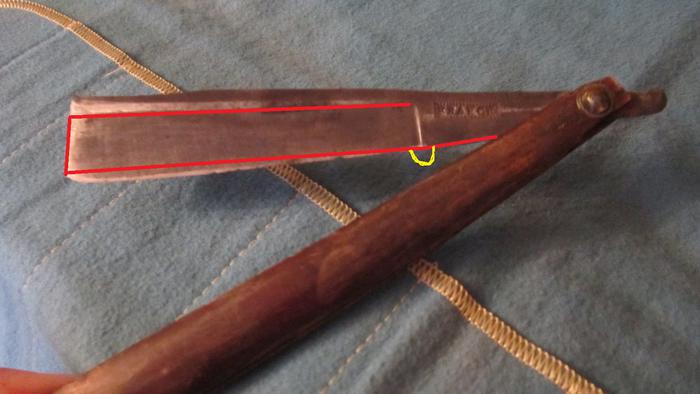

Thanks so much for all the help. There's one thing I still want to to clear up though. How should I approach the shoulder? I'd hate to mess up the profile of the razor. It has that distinct triangular shape and I'd like to keep that but I'm having a hard time wrapping my head around how I would keep the crisp lines and not round them. I'll attach pictures in case what I am saying is unclear. Green is the original blade profile and the way I'd like to keep it. I drew the first after picture to demonstrate how I would have to grind into the shoulder/tang to keep original profile. The second pic in red is showing where if it was ground while avoiding the tang the shape it would take. As you can see the face of the blade would be more rectangular and the transition line to the tang wouldn't be so straight. Should I just take a little bit off the tang in order to ensure the transition stays straight? I may be over thinking things here. Thanks again!

-

01-29-2015, 01:33 PM #7Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yea, overthinking it a bit.

You have to remember with that blade shape it is not going to hone symmetrically across the bevel anyway, which is why the angle of the edge is not perfectly straight now.

I would remove as little steel as possible and alter the shape, by cutting into the tang. I don’t think you will really take too much off the tang to get it to look straight.

As you will see when you put a straight edge on the edge, it is not very straight now, especially at the tip.

It will have to be a judgment call once you start to remove the chip, and do what it takes to make it look straight, even though it may not be perfectly straight.

I would remove as little steel as possible.

How cool is that, to shave with something that old?

-

The Following User Says Thank You to Euclid440 For This Useful Post:

StraightOverload (01-29-2015)

-

01-29-2015, 03:21 PM #8

I began removing large chips breadknifing. I call it 'the nuclear option.' By attacking the blade in the same fashion you would a pocket knife, IOW honing it at an angle with the spine raised off of the hone, you are creating a bevel while you are removing metal to get past the chip.

Breadknifing leaves you with the chip gone but now you have to create the bevel and there is a hell of a lot of metal to take off. My way may not take less time, but IME it works better. I guess it is a pay me now, or pay me later situation, as far as the time it takes is concerned.

I know that, having done more than a few, I prefer the pocket knife method to the breadknife method without exception. Like everything else in this sport ....... YMMV ......... Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

The Following 2 Users Say Thank You to JimmyHAD For This Useful Post:

ScottGoodman (01-30-2015), StraightOverload (01-29-2015)

-

01-29-2015, 06:15 PM #9

That's what I was sort of thinking. I'm not too concerned about the bevel. I would like to keep the transition of it into the tang as straight as possible but we'll see. On the other hand, I'd hate to ruin the patina on the tang. Whatever course this takes, it should be a great learning experience. I've only honed chips out of a couple blades and the worse was a Torrey that was a full hollow or half. To put the final nail on the coffin, the blade was terribly warped at the toe. Took a heck of a lot of learning to get that razor shaving. That razor taught me about honing chips and warps! I have a lot to thank that old razor for.

This will be by far the oldest razor I have. It just makes me all giddy imagining myself shaving with!Last edited by StraightOverload; 01-29-2015 at 06:17 PM.

-

01-29-2015, 11:33 PM #10

I say send the old boy off to someone who knows how to hone properly & remove only the chips as needed & keep the original shape as much as possible

Just my 2 cents hate to see a awesome old blade get bread knifedSaved,

to shave another day.

12Likes

12Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote