Results 1 to 9 of 9

Thread: cant do buffalo horn flat :)

-

02-14-2015, 09:47 PM #1

cant do buffalo horn flat :)

cant do buffalo horn flat :)

i have many buffalo horn that they are not flat, i did search on net, i read on this forum, i did have them i oven, i boiled them in water and in oil, they dont want to be flat, can someone give me a good advice.

-

02-14-2015, 10:05 PM #2Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

I have two g10 blanks that I ordered too thick (3/8). I boil the horn until it is soft, place it between the g10 blanks and clamp it down. Not too hard because the horn will split with too much pressure. I then put it into the freezer, then after it is frozen I take it out and leave it long enough to thaw to room temp, still clamped. This has worked multiple times for me, but there are several methods that are available.

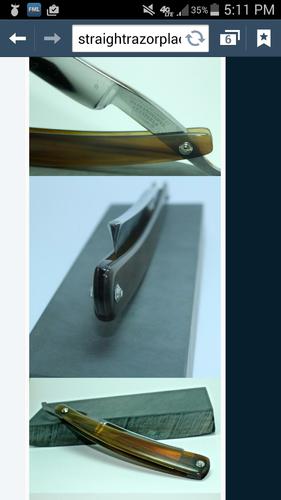

These scales were from a very warped blank...

Last edited by prodigy; 02-14-2015 at 10:10 PM.

-

The Following 2 Users Say Thank You to prodigy For This Useful Post:

Geezer (02-15-2015), HARRYWALLY (02-14-2015)

-

02-14-2015, 10:16 PM #3

first of all thanks for answer, did u boil i water or oil?

-

02-14-2015, 10:24 PM #4Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

Yes boiling water is the method I used. Do you have pictures of your blanks? Mine were 6 in long x 2 in wide x 3/8 in thick. I boiled them in water until they became soft, usually less than 1-2 minutes. The key is to quickly get them in a straightened position with slight pressure. Once they have been straightened they can warp again so I try to make sure I can take them from being straightened to being finished with a razor in the same day.

-

02-15-2015, 12:35 AM #5

ok u mean that u try to pin the scales at once after straightened , what do u do if they get wrap after u pined the scales, its not better to wait and see if they will warp or not and then pine them.

-

02-15-2015, 12:41 AM #6Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

I think there are just factors that make them warp, like humidity and temperature. I'm not really an expert so maybe one will chime in soon. I feel that if you pin it properly, while the horn is straight, the tension will prevent it from warping. I only had one set warp after I initially straightened them, and that was because I left them out for several days. Every razor is different, it just depends. Sometimes the blades are not straight, and a slightly warped scale might help it center better than a perfectly straight one.

-

02-15-2015, 12:56 AM #7Senior Member

- Join Date

- Dec 2011

- Location

- I'm Gonna Spend Another Fall In Philadelphia

- Posts

- 2,002

Thanked: 498

I've often come across many a warped horn panel. I also realized early on its better to straighten them after the initial cutting of the pattern. For me its easier to straighten a scale then a whole panel. Less surface area to deal with. I steam then in a pot with a vegetable steamer. I'll then clamp them to a plate and quench them in cold water. sometimes I'll even place a clothes pin half underneath to reverse over bend it for the stubborn scales..

-

02-15-2015, 02:57 AM #8Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

True, I've done it with the scale after its been shaped. Depending on how bad the warp is though it might be necessary to flatten the blank to get a good scale. I use an orbital sander on the 3/8 blank until it's the right thickness, and if it's really warped it's best to try and flatten first, IMHO.

-

02-15-2015, 03:01 AM #9Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

Horn can be fun :<0) I heat mine with a hair dryer until they are almost hard to hang onto and then clamp flat. Toss in the freezer for a couple of hours and when I take them out I leave clamped until they are room temp. If they are twisted several different ways I shim with paper to sort of over straighten them. They key is the deep freeze. Seems to lock them in place.

Heat is what makes them flat in the first place or warps them later, or they just didn't stay flat from the first process. Sanding and cutting is heat. Sometimes concentrated in one place.

My buddy Zak put all this in a neat little tutorial for you guys. Surprised your search didn't turn it up.

http://straightrazorpalace.com/works...rn-scales.html

Sometimes you just have to do this more than you would ever want but like I said,,,,Good judgment comes from experience, and experience....well that comes from poor judgment.

12Likes

12Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote