Results 1 to 10 of 13

Thread: Carbon fiber drilling problem

-

04-01-2015, 06:04 PM #1Member

- Join Date

- Feb 2015

- Location

- Ireland

- Posts

- 42

Thanked: 8 Carbon fiber drilling problem

Carbon fiber drilling problem

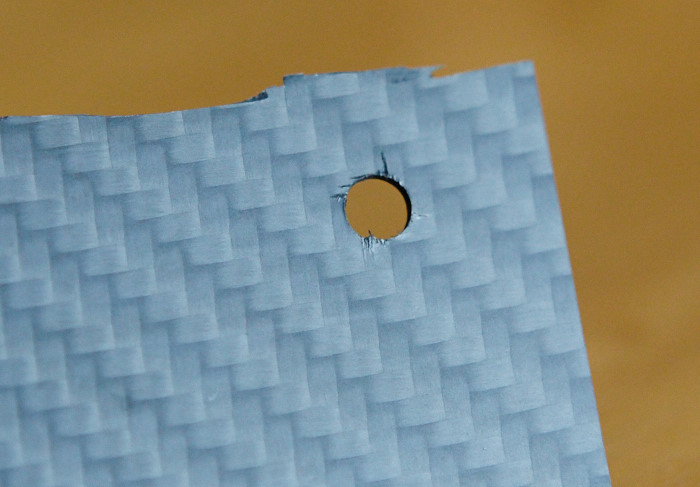

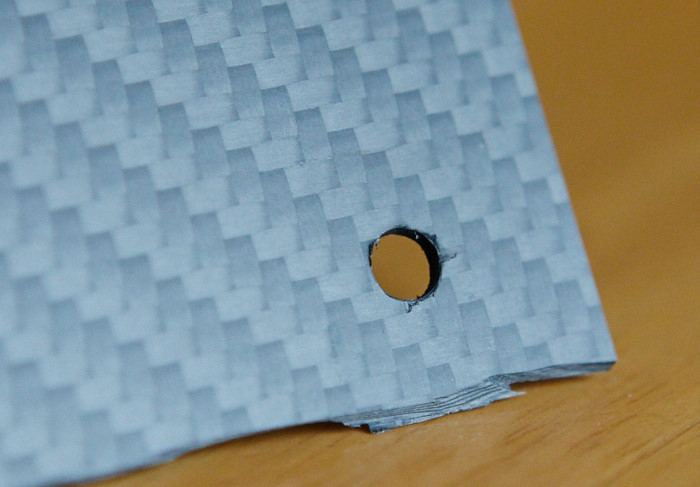

My first attempt to make carbon fiber scales. Please have a look at these photos (both scales, both sides).

Drilled in two stages first 2 mm diameter and second time 5 mm. Hand held drill (only have this one) low speed and low pressure. Fibers looks like they are torn.

Both drills was brand new, sharp and a good quality ones, these drills are for metal.

Any tips how to avoid it?

-

04-01-2015, 06:19 PM #2

I use masking tape on the top and bottom where I'm going to drill. Backing the CF with a piece of wood helps a lot. I drill through the CF and the wood. Clean cut. A manual reamer does also a very good job.

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

The Following User Says Thank You to Maximilian For This Useful Post:

cthulhu (04-01-2015)

-

04-01-2015, 06:51 PM #3

Agreed, tape it and use a backer.

-

04-01-2015, 07:03 PM #4Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Try a split point bit,Carbon fiber comes in many diff,grades and weaves.The cheap stuff will do the above every time.

CAUTION

Dangerous within 1 Mile

-

The Following User Says Thank You to pixelfixed For This Useful Post:

cthulhu (04-01-2015)

-

04-01-2015, 07:37 PM #5Member

- Join Date

- Feb 2015

- Location

- Ireland

- Posts

- 42

Thanked: 8

Guys, many thanks for advice

Tomorrow I'll try taping and drill on wood, if that fails then probably split point bit.

-

04-01-2015, 08:50 PM #6

Definitely tape on both sides.

Drill the hole on high speed with very light pressure and one bit size smaller than the hole size you need. Then use a countersink on high speed to go to the final hole diameter.

If you get tear out then you are using too much pressure.Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

The Following User Says Thank You to criswilson10 For This Useful Post:

cthulhu (04-02-2015)

-

04-02-2015, 01:59 AM #7

Here is a link to a webinar discussion about different composites.

Drilling and Trimming of Carbon Fiber and Composites: https://youtu.be/Xh0VJOW5kps

From what I've seen and worked, tape,high speed, drill from shinny side (this minimizes delamination of finished side topcoat), come in with a countersink to break edges after drilling to clean up.

-

The Following User Says Thank You to lethalgraphix For This Useful Post:

cthulhu (04-02-2015)

-

04-02-2015, 09:22 AM #8

I would personally look at trying a regrind on your drill bit to a steeper angler from the standard 135 degrees to something closer to 100 degrees to help cut the fibre edges better

With the same drill speed but a slower feed speed when drilling

JmoSaved,

to shave another day.

-

The Following User Says Thank You to Substance For This Useful Post:

cthulhu (04-02-2015)

-

04-02-2015, 02:33 PM #9Member

- Join Date

- Feb 2015

- Location

- Ireland

- Posts

- 42

Thanked: 8

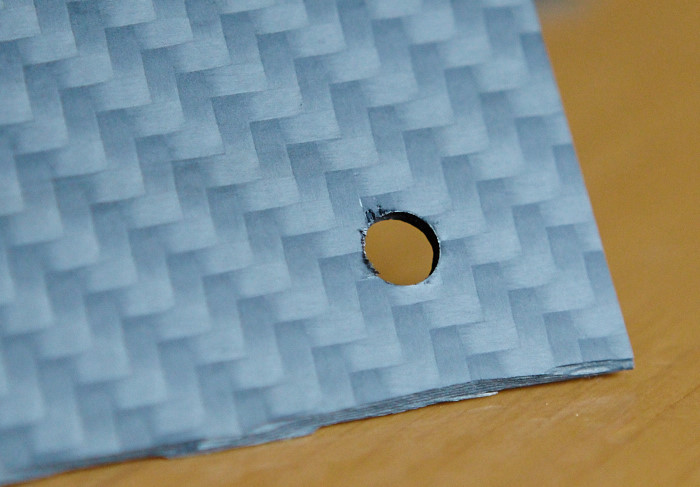

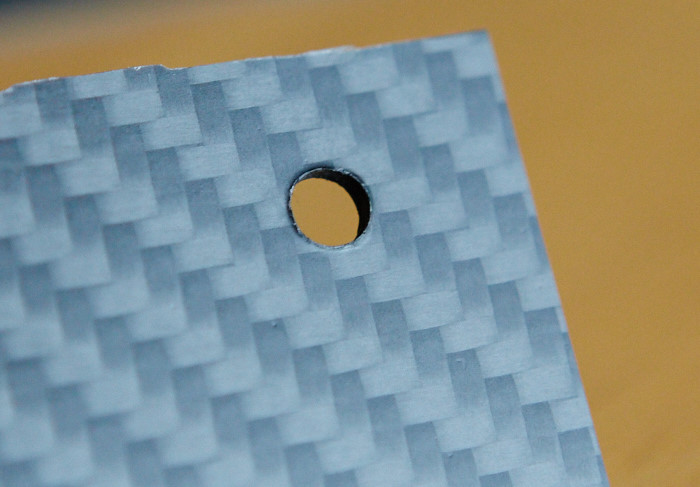

A quick test done. Masking tape and wood behind. Max speed on my drill and very slow progression. Everything else the same. Results are much better. Will upload photos later.

-

04-02-2015, 05:59 PM #10

Start with 4 minutes. Just need more speed. Sorry for the Russian language.

6Likes

6Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote