Results 11 to 16 of 16

Thread: Box joint jig.....

-

06-12-2015, 02:58 AM #11illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

Well Randy, if you need inspiration, I managed to tap two, that's right two, holes tonight!

I look forward to your finished product. I too hope to make a box some day.

-

06-13-2015, 01:41 PM #12Junior Member

- Join Date

- Apr 2014

- Posts

- 15

Thanked: 2

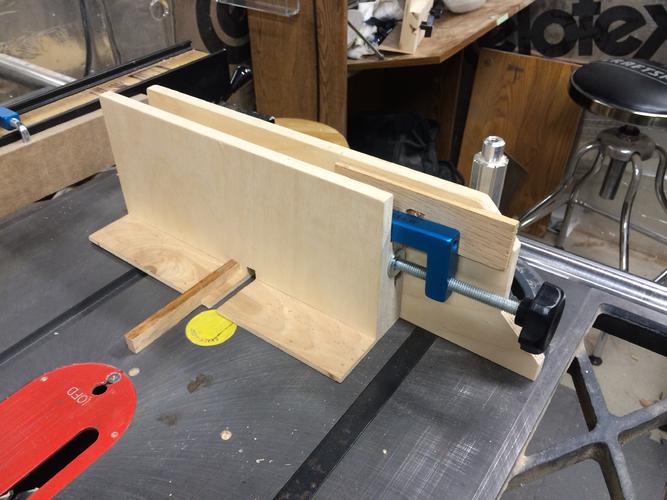

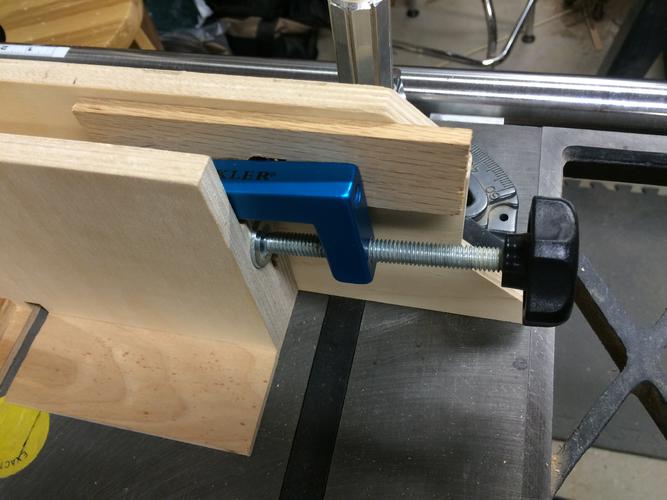

Here are some pics of my jig. This is only for a 3/8 joint and can be used on the table saw OR the router table. I worked the adjustment idea over and over in my head and arrived at the simplest solution I could find - a Rockler universal fence clamp. One hole in the back of the jig holds the pin and the adjustment knob moves the front half. The downside of this arrangement is that it only adjusts one way. I'd love to find a simply way to adjust it backwards and forwards. One step at a time.

-

The Following User Says Thank You to Padre For This Useful Post:

randydance062449 (06-13-2015)

-

06-13-2015, 02:12 PM #13Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

That is pretty close to the same design that I use too

It's not what you know, it's who you take fishing!

-

06-13-2015, 03:43 PM #14Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

-

06-13-2015, 05:17 PM #15Junior Member

- Join Date

- Apr 2014

- Posts

- 15

Thanked: 2

Yes, I think I could do that. I'll look into it. It needs some more tweaking, but could be done fairly easily.

-

06-13-2015, 05:31 PM #16Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I was thinking some more about this and may have a better idea. I will talk with you about this next week. It is a simple idea that would allow back and forth adjustments with the turn of a single knob, a threaded shaft that runs the full length of the back piece thru a threaded nut that is attached to the back side of the front piece of the jig. I am sure that something is missing but it is a start.

Last edited by randydance062449; 06-13-2015 at 05:49 PM.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

32Likes

32Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote