Results 1 to 4 of 4

-

05-14-2015, 09:35 PM #1Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315 Stamping Bullseye & Support Washers

Stamping Bullseye & Support Washers

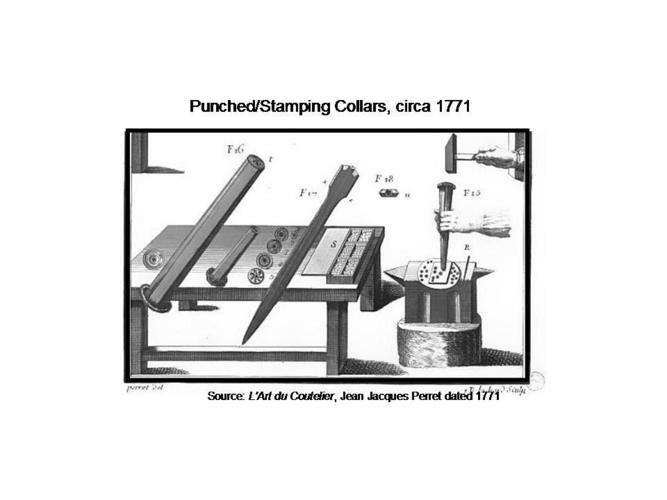

Is there anyone who could provide the dimensions for a punch used to make bullseye washers. I found a thread where ScienceGuy made one that produced nice washers, but I didn't see anything about its' dimensions. I know the bullseye washers were not all the same size, but it would be helpful to know the dimensions of a punch that someone has used successfully. I'm hoping I can eventually have a machinist make one for me, so I'm trying to get the information that they would need.

Also, a question about how the original bullseye washers were made. Were the punches used by cutlers of the time also made with a protruding shape on the end, or were they recessed?

Thanks

-

05-15-2015, 10:40 AM #2

You could try to reinvent the wheel or you could buy what ajkenne (a member here) has already made. I've bought some from his eBay store but have yet to receive them. There are four types and look perfect.

Than ≠ Then

Than ≠ Then

Shave like a BOSS

-

05-15-2015, 10:53 AM #3

Well You could give them a finished washer/collar and have them make a punch to fit it.. you'd be surprised what a good machinist can work from

-

05-16-2015, 10:32 PM #4Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

Thanks for the input so far guys.

I've already ordered some. They look nice, but they are not as large as what I want, and the hand stamped ones seemed to be smoother in the pictures.

I've considered that. The only thing is, with the stretching that occurs when you stamp the sheet metal, I'm not sure you can measure everything from the finished product. If I can save the machinist some of the trial & error for them to come out right, I think that would be helpful.

3Likes

3Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote